A hydraulically driven modular pump frac skid

A technology for driving modules and hydraulic pumps, which can be applied to machines/engines, wellbore/well components, and production fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

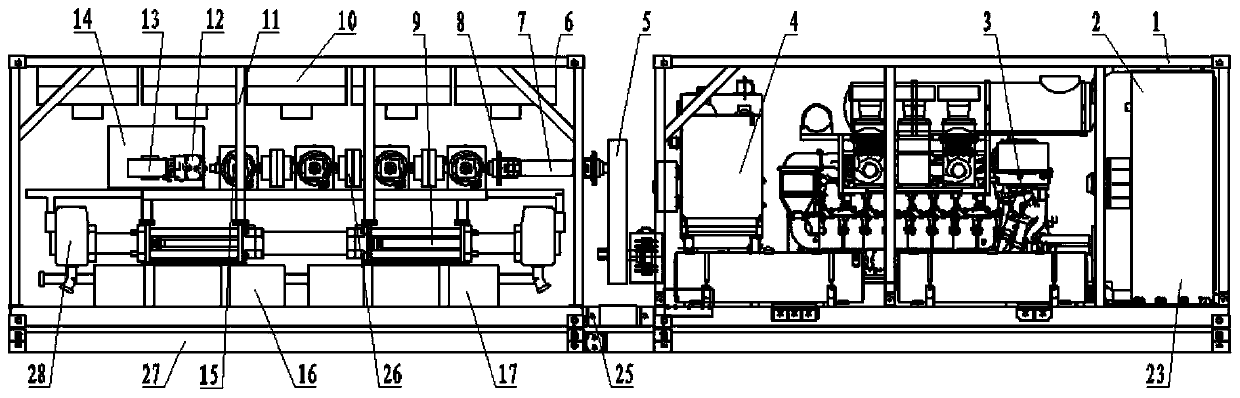

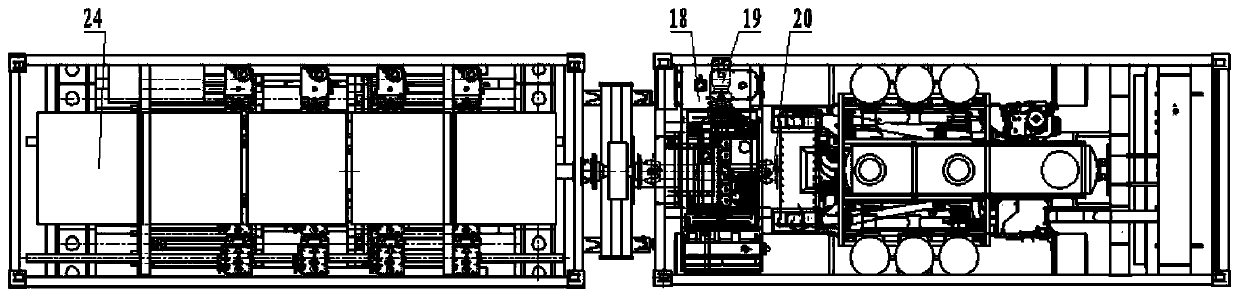

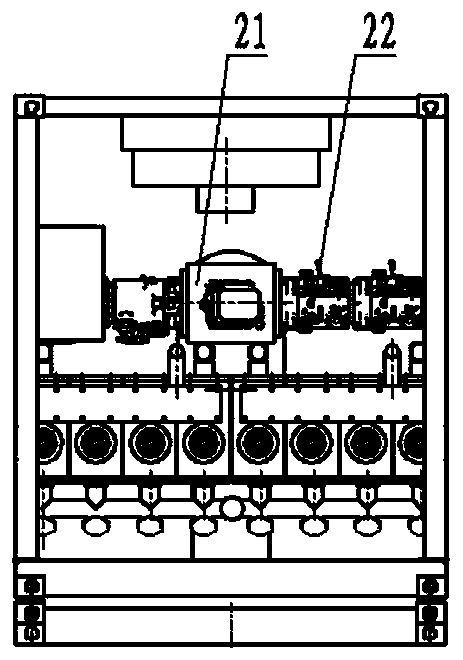

[0027] The present invention is a hydraulically driven modular pump frac skid, such as figure 1 , figure 2 , image 3 As shown, the power skid 1 and the fracturing pump skid 6 are included, and the bases of the power skid 1 and the fracturing pump skid 6 are both provided with V-shaped connecting lugs, which are connected by a pin 25 . The front end of the power skid 1 is provided with a vertical radiator I2, the middle is provided with a main engine 3, and the rear end is provided with an auxiliary engine 4 and a hydraulic system I18. The auxiliary engine 4 is directly connected to the hydraulic pump of the hydraulic system I18 through a shaft coupling and a fixed flange. One way of the hydraulic system I18 drives the radiator I2, and the other way is used for starting the main engine 3 . The main engine 3 is connected to the gearbox 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com