Design method of liquid ring angular accelerometer and modeling method of dynamic-pressure process

An angular accelerometer and modeling method technology, applied in the field of model identification, can solve problems such as large amount of calculation, limited prior knowledge, low modeling efficiency, etc., to achieve high-precision dynamic-pressure process modeling, identification model simplification, The effect of simplifying the modeling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

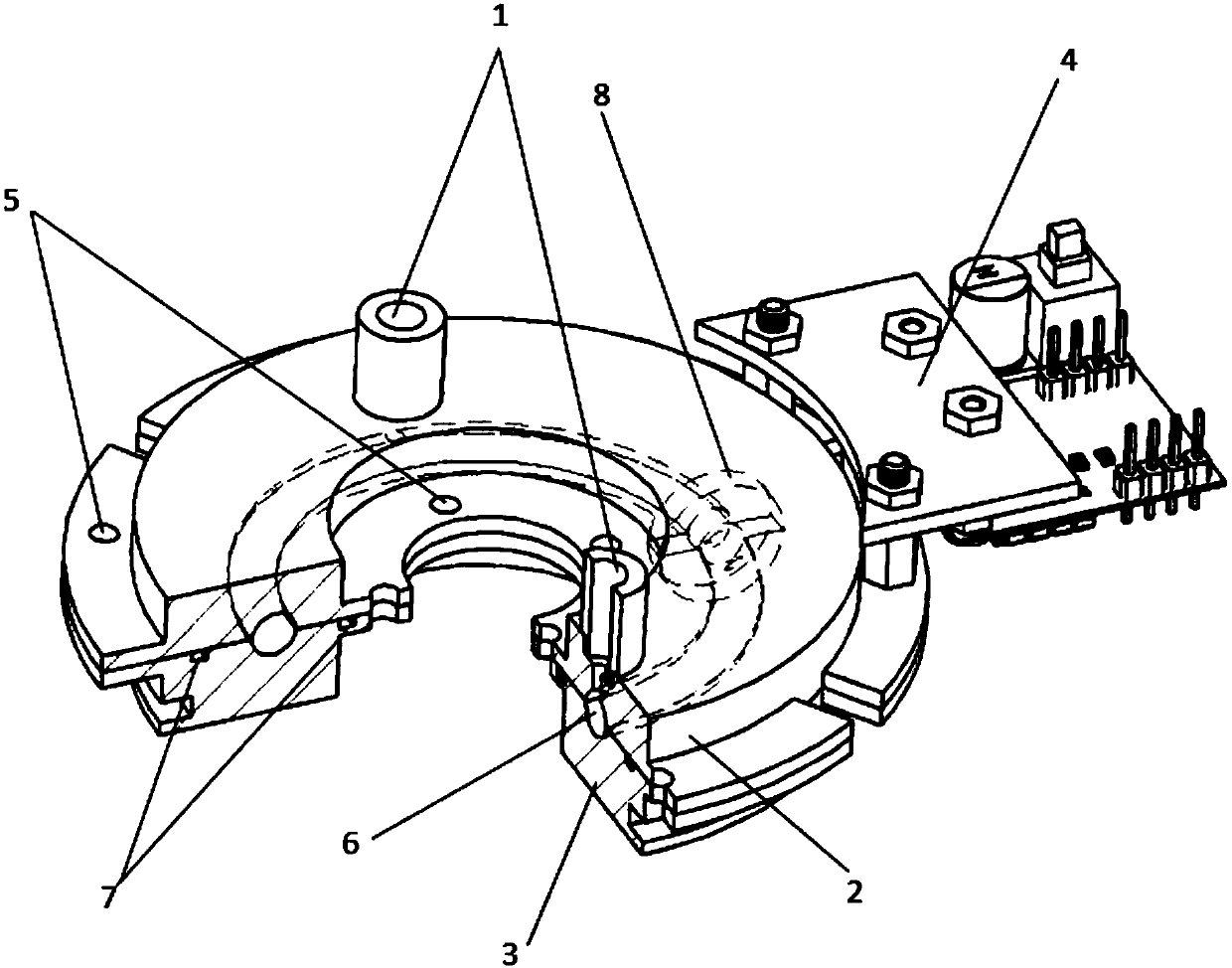

[0044] The present invention will be described in detail below with reference to the accompanying drawings and examples.

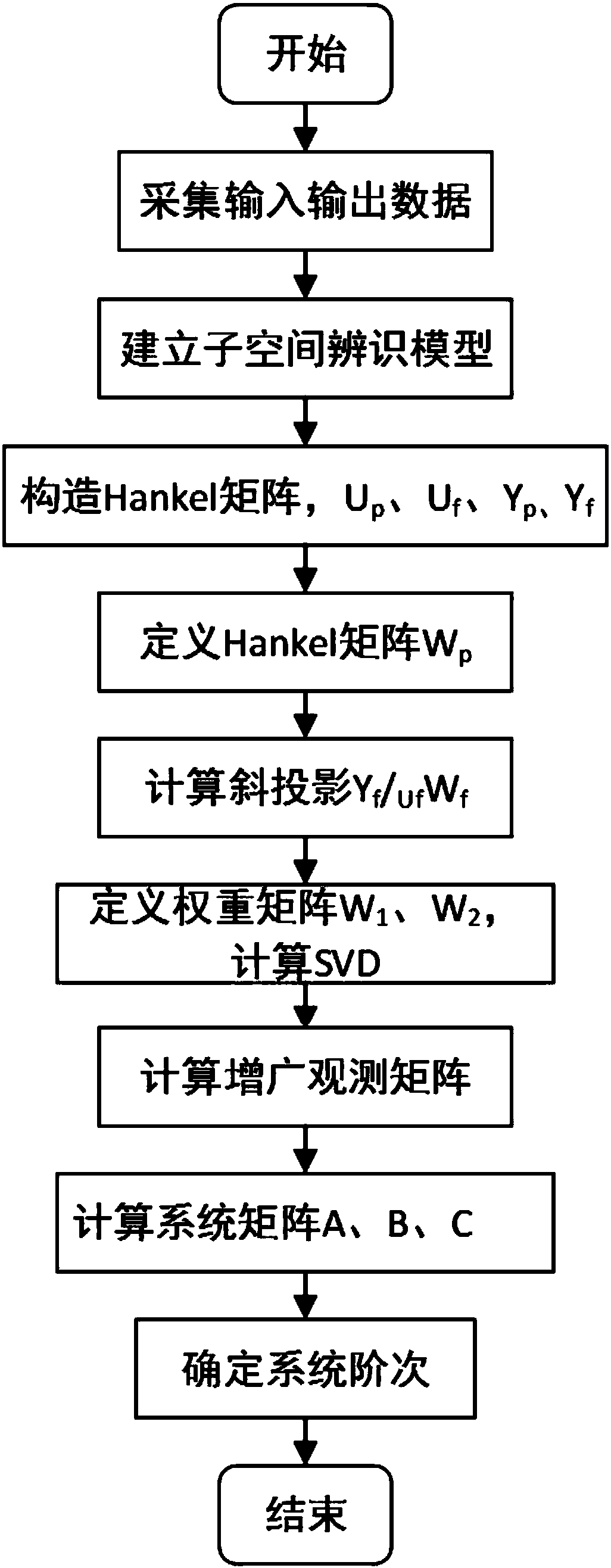

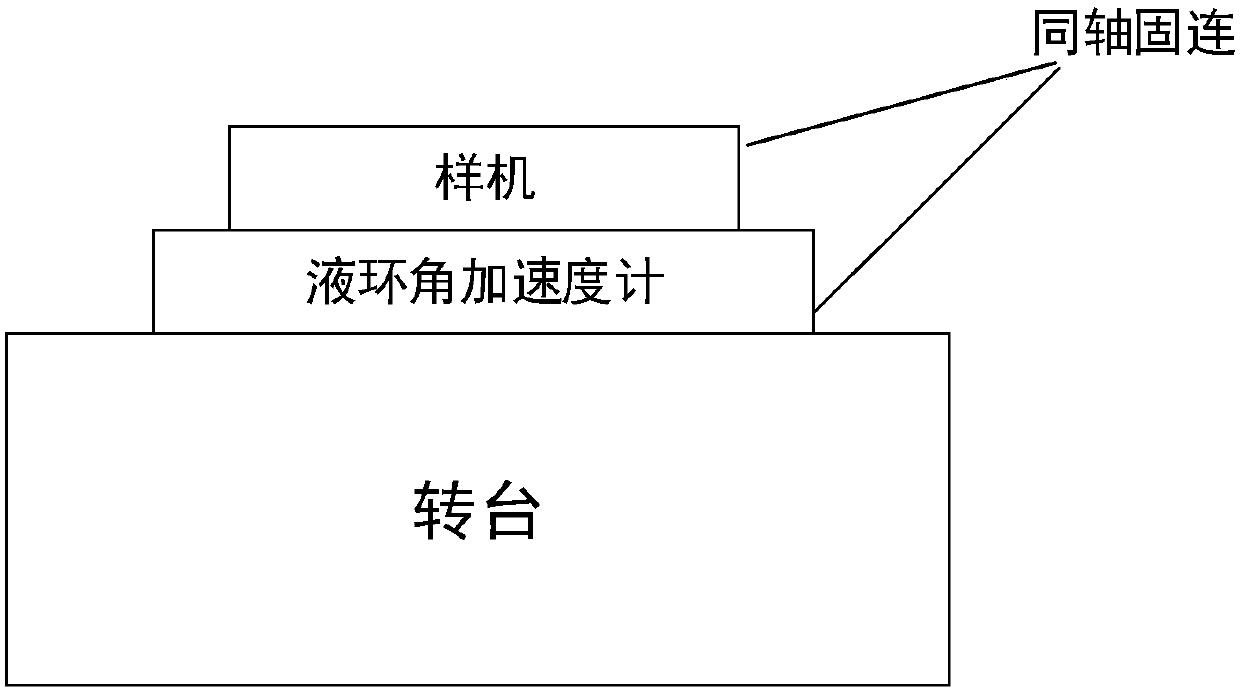

[0045] When the external angular acceleration signal is input, the inertial liquid will move relative to the liquid ring cavity, and a pressure difference will be generated between the two ends of the piezoelectric transducer. The present invention deduces the relationship between the angular acceleration and the pressure difference of the liquid ring angular accelerometer. The relationship between the angular acceleration of the angular accelerometer and the pressure difference simplifies the subspace identification method, and uses the simplified subspace identification method to model the dynamic-pressure process, realizing high-efficiency, high-precision liquid ring angular acceleration Meter dynamic-pressure process modeling, liquid ring angular accelerometer dynamic-pressure process modeling process is as follows figure 1 shown.

[0046] The modelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com