Slurry concentrating and stirring device

A stirring device and slurry technology, which is applied to the feeding/discharging device of the settling tank, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the concentration effect and overflow water quality, large investment, high energy consumption, etc., to achieve Reduce the cost of daily operation and maintenance, improve the concentration efficiency, and the effect of simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

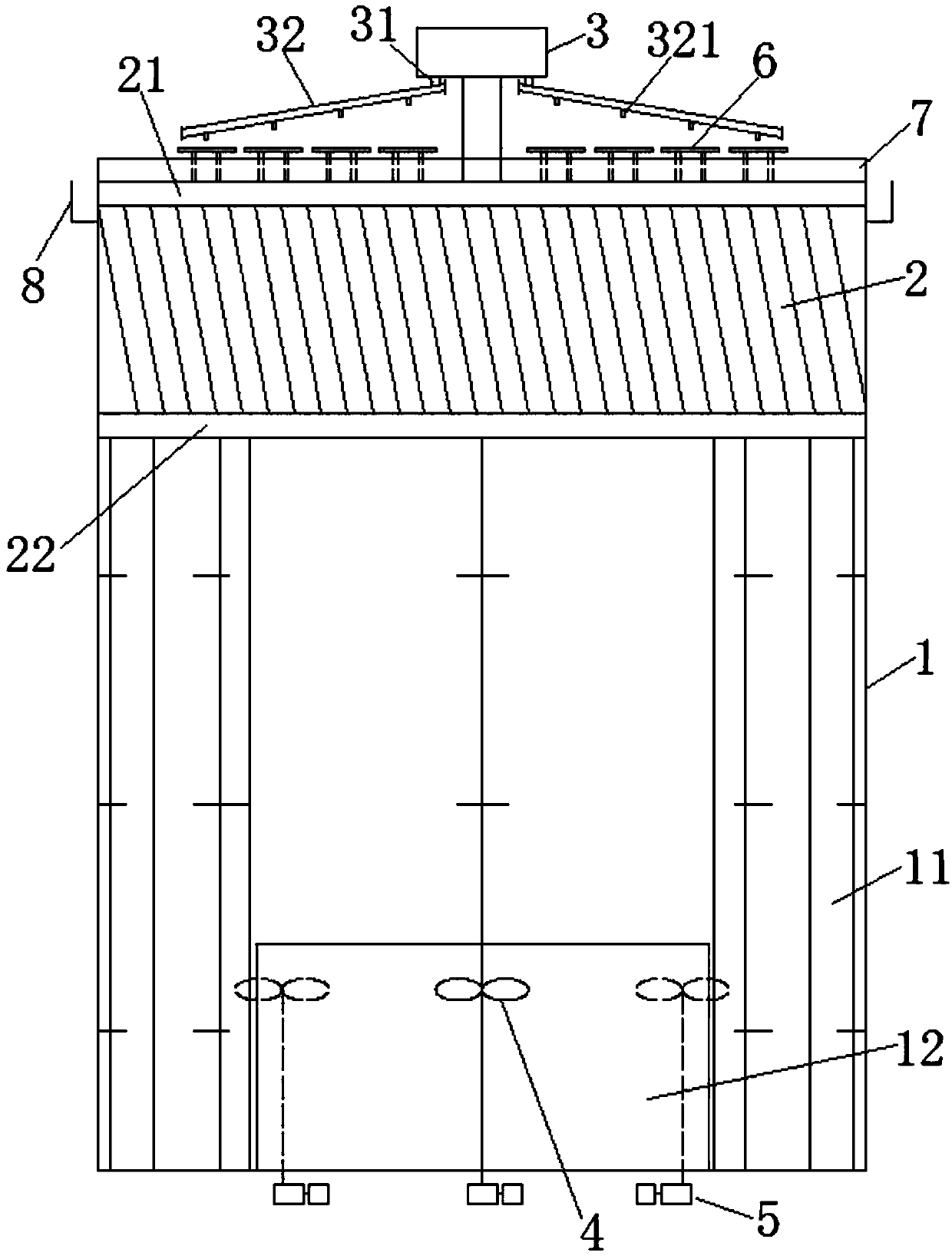

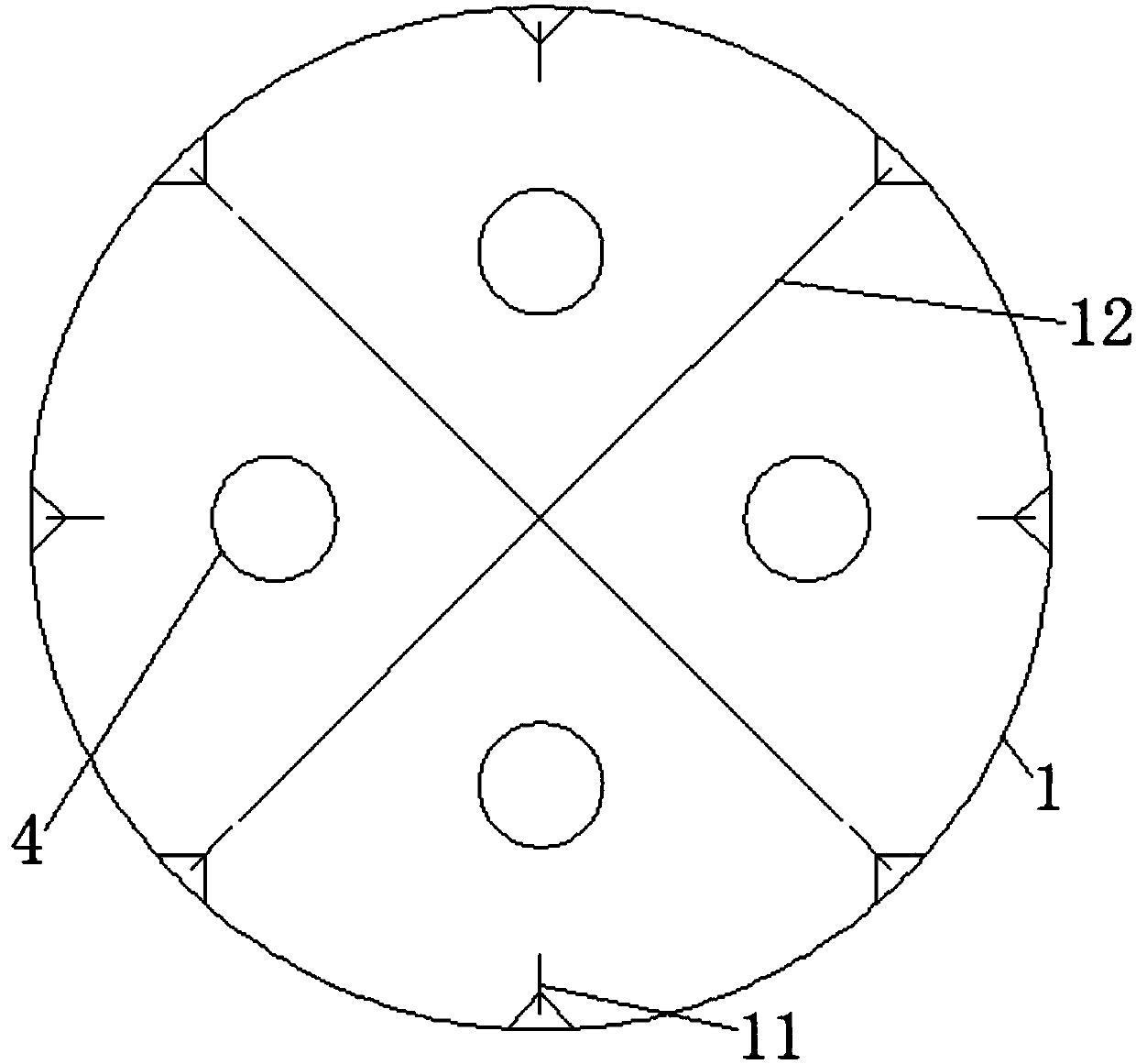

[0035] Example: such as Figures 1 to 3 As shown, the slurry concentration stirring device of this embodiment includes a stirring tank 1, a swash plate device 2 and a distribution tank 3;

[0036] The above-mentioned stirring tank 1 is a cylindrical structure with a hollow interior and an open upper end, and has a discharge port at the bottom;

[0037] The inner bottom wall of the stirring tank 1 is evenly provided with a plurality of stirring mechanisms 4; the plurality of stirring mechanisms 4 are respectively one-to-one correspondingly connected with the stirring drive device 5;

[0038] The above-mentioned inclined plate device 2 is a cylindrical structure matching the opening end of the above-mentioned stirring tank 1, and is coaxially installed in the opening end of the above-mentioned stirring tank 1;

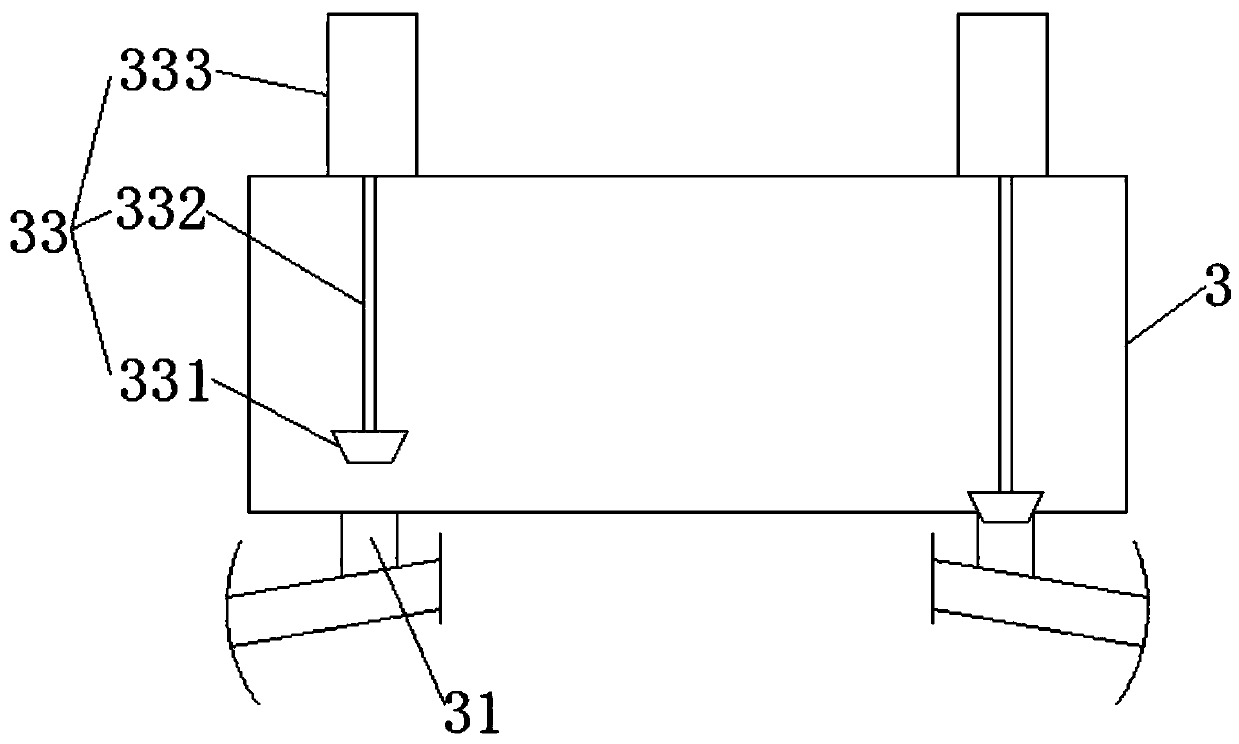

[0039] Above-mentioned dispensing tank 3 is arranged above the middle part of the opening end of above-mentioned stirring tank 1, and its bottom is provided with a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com