High-selectivity CO2 reduction photocatalyst, preparation method and application

A photocatalyst and high-selectivity technology, which can be used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

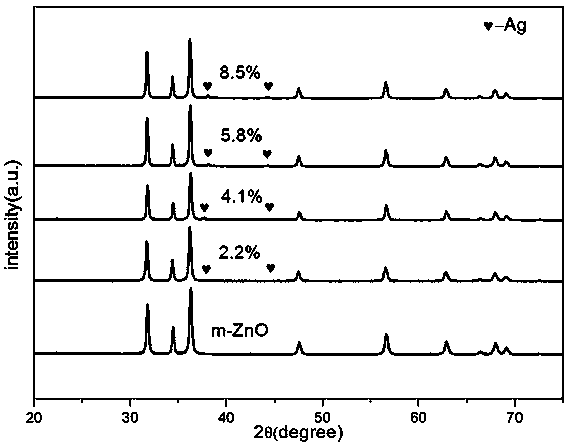

Embodiment 1

[0028] (1) Weigh 0.08g of anhydrous zinc acetate into 60mL of ethanol, and keep stirring for 40 minutes to fully dissolve;

[0029] (2) With the conductive surface of the cleaned conductive glass (FTO) facing up, dip it in the above solution for 20s, then take it out, and dry it with argon gas; repeat the dipping-argon gas drying step 6 times;

[0030] (3) Then transfer the impregnated conductive glass to a tube furnace, control the heating rate, raise the temperature to 350°C at a rate of 3°C / min, and roast it in the air atmosphere for 30min to obtain a conductive glass uniformly covered with zinc oxide crystals. Glass;

[0031] (4) Weigh 0.48g of zinc acetate dihydrate in 30mL of deionized water, stir until clear and transparent to obtain solution A; meanwhile weigh 0.43g of urea in 30mL of deionized water, stir until clear and transparent to obtain solution B; Pour and B into a 100mL polytetrafluoroethylene autoclave at the same time, stir for 10 minutes to make it fully m...

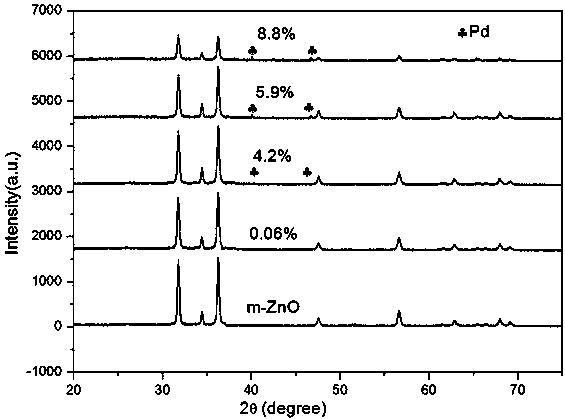

Embodiment 2

[0037] In step (7) of Example 1, 20 μL of 20 g / L silver nitrate was changed to 40 μL of 10 g / L palladium chloride, and the rest of the preparation method and activity testing method were basically the same as in Example 1.

Embodiment 3

[0039] In step (7) of Example 1, 20 μL of 20 g / L silver nitrate was changed to 40 μL of 20 g / L silver nitrate, and the rest of the preparation method and activity testing method were basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com