Preparation method of piezoelectric sensor assembly

A technology of piezoelectric sensors and piezoelectric elements, applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve problems such as poor stability, low manufacturing efficiency of piezoelectric sensor components, and unsuitability for large-scale production, and achieve Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a piezoelectric sensor assembly, such as Figure 5 As shown, the specific steps include the following:

[0044] S1. Use the mold to press the low-melting-point tin-brazing powder into tin-brazing rings with dimensions of Φ4.5×4.0×4mm and Φ8.0×7.5×4mm to obtain low-melting-point metal layers in different sizes. 12 and outer low melting point metal layer 18;

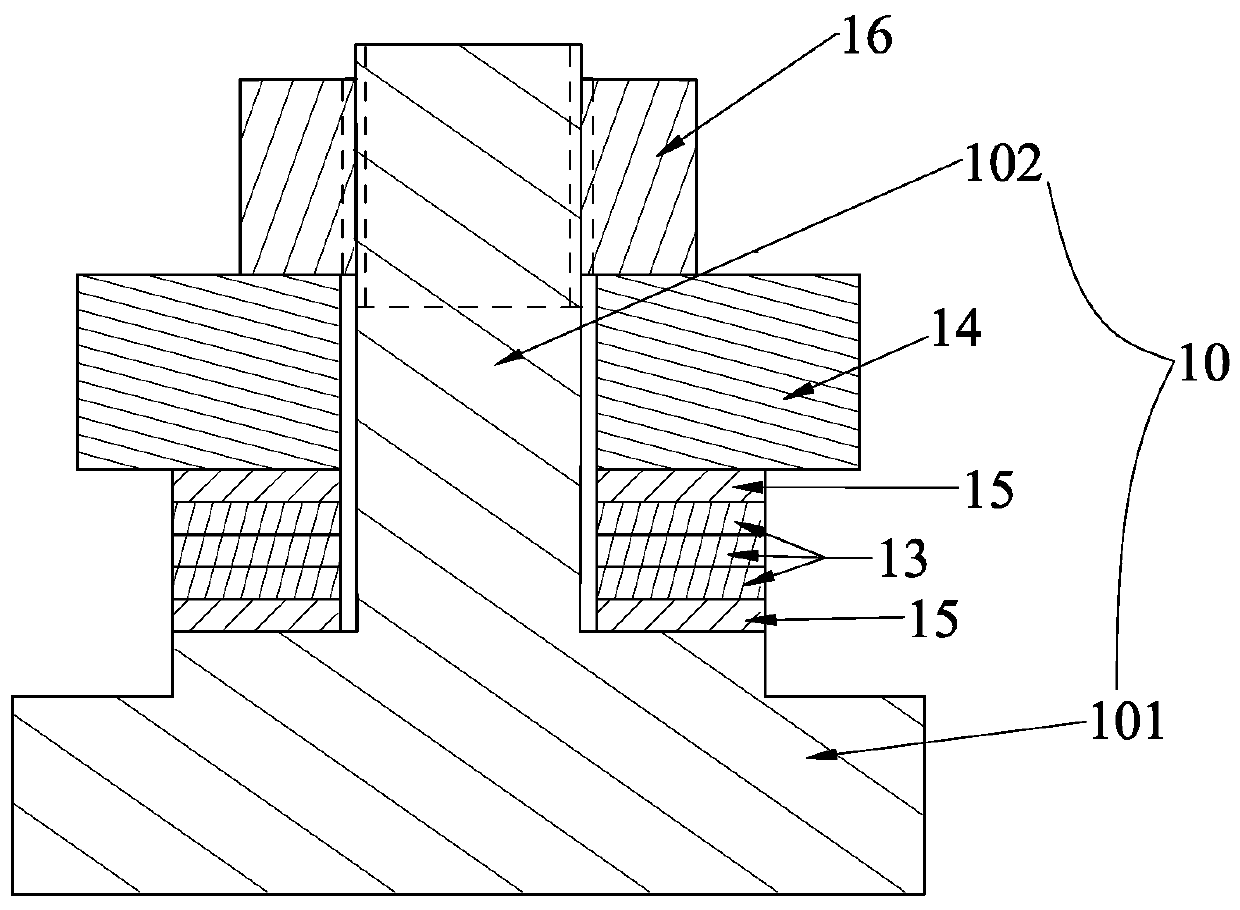

[0045] S2. Put the jig 11 of a certain thickness into the bottom of the sleeve rod 102 of the base 10, and the outer diameter of the sleeve rod 102 is Φ4.0mm;

[0046] S3. See Figure 5, put the Φ4.5×4.0×4mm inner low-melting-point metal layer 12, Φ7.5×4.5×4mm piezoelectric element 13, Φ8.0×7.5×4mm outer low-melting-point metal around the sleeve rod 102 on the jig 11 layer 18, and then put the Φ12.5×8.0×5.5mm mass block 14 into the sleeve rod, so that the inner low melting point metal layer 12, the piezoelectric element 13, and the outer low melting point metal layer 18 are sandwiched betwe...

Embodiment 2

[0051] A method for preparing a piezoelectric sensor assembly, such as Image 6 As shown, the specific steps include the following:

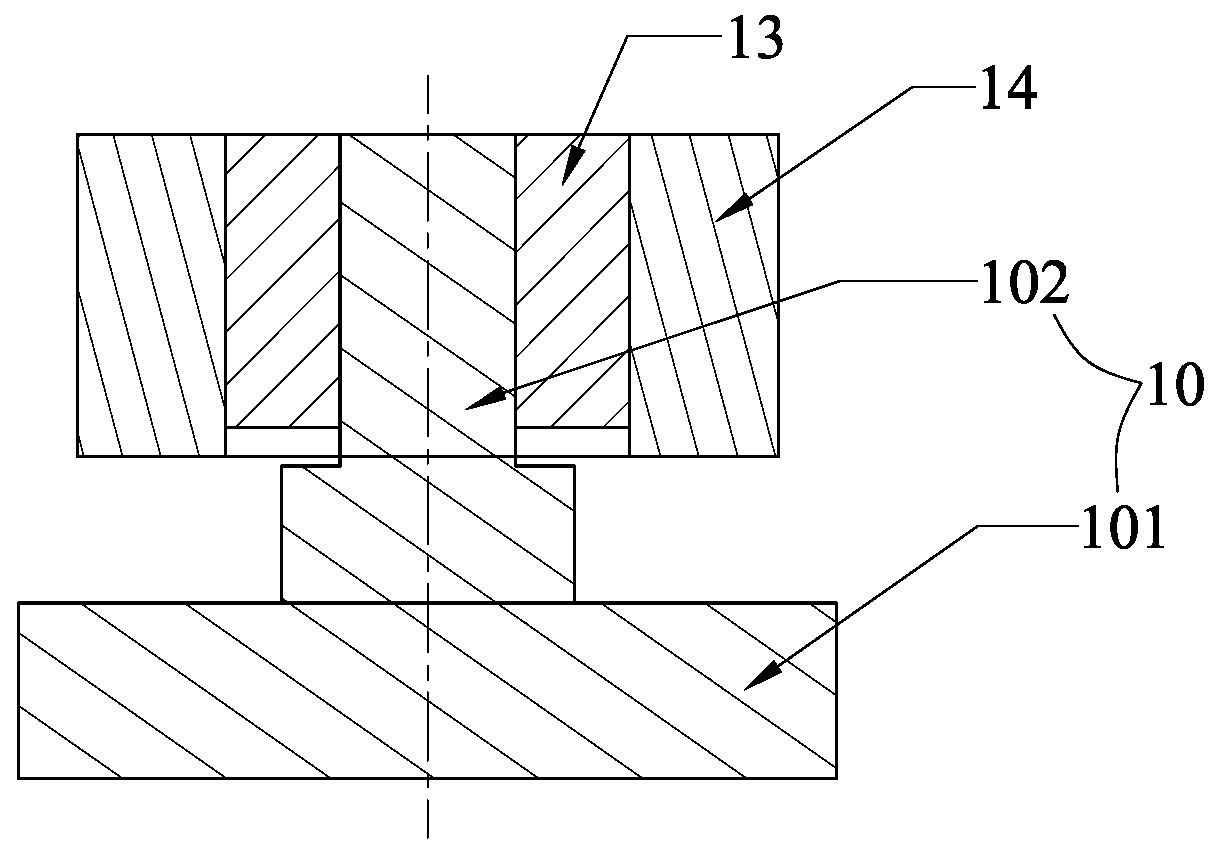

[0052] S1. Use a mold to press the low-melting-point tin brazing powder into two square sheets with a size of 4.0×5.0×4.0 mm to obtain a square inner low-melting-point metal layer 12 and an outer low-melting-point metal layer 18;

[0053] S2. Insert the jig 11 of a certain thickness into the bottom of the rod 102 of the base 10;

[0054] S3. See Image 6 , put the inner low-melting-point metal layer 12, the piezoelectric element 13, and the outer low-melting-point metal layer 18 in order around the sleeve rod 102 on the jig 11, and then put the mass 14 into the sleeve rod 102, so that the inner low-melting-point metal layer 12 1. The piezoelectric element 13 and the outer low melting point metal layer 18 are sandwiched between the sleeve rod 102 and the mass block 14, and the piezoelectric element 13 is sandwiched between the inner low melting...

Embodiment 3

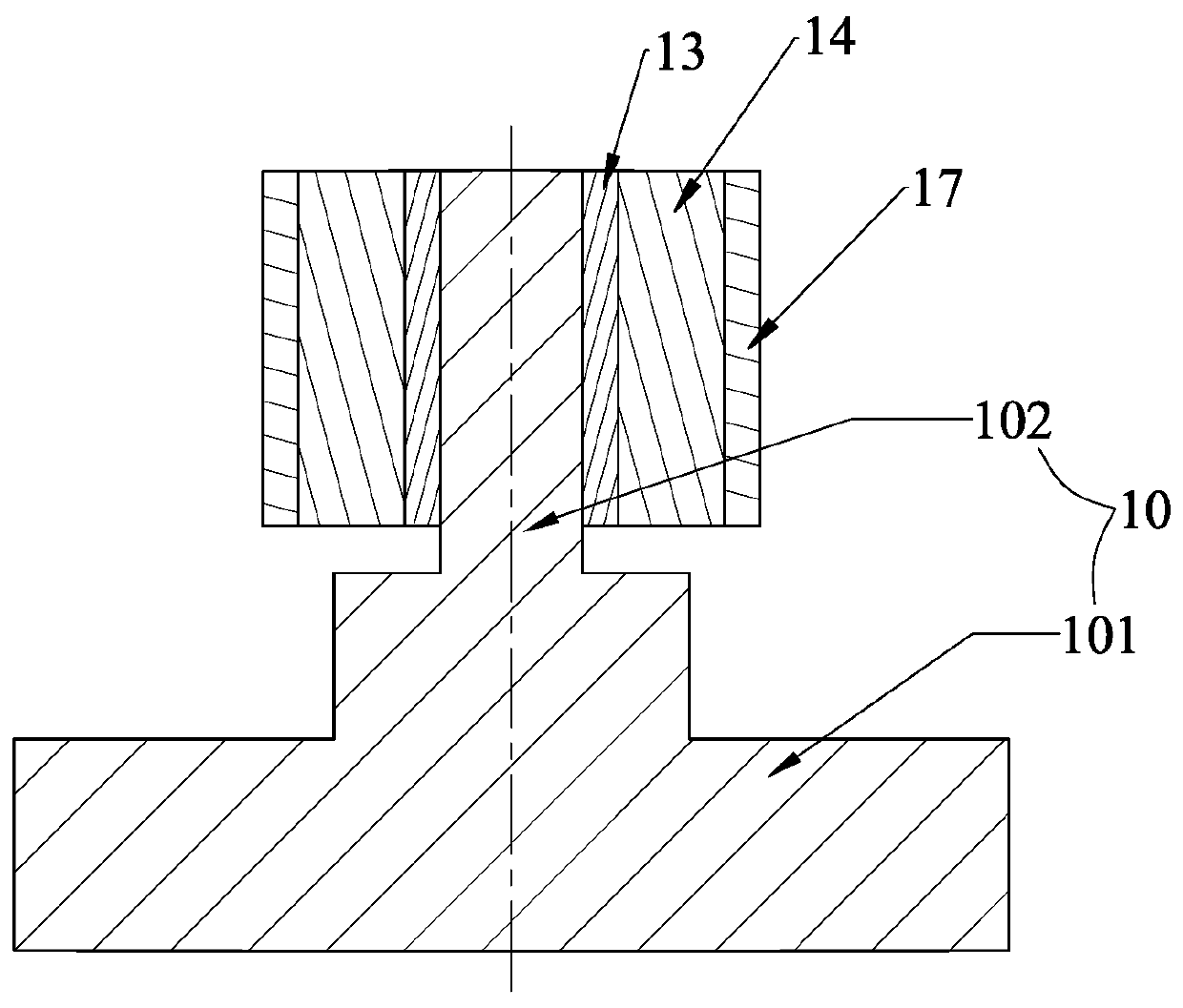

[0059] A method for preparing a piezoelectric sensor assembly, such as Figure 5 As shown, the specific steps include the following:

[0060] S1. Use a mold to melt the low melting point tin brazing powder and pour it into tin brazing rings with dimensions of Φ4.5×4.0×4mm and Φ8.0×7.5×4mm to obtain a circular inner low melting point metal layer 12 and outer low melting point metal layer 18;

[0061] S2. Put the jig 11 of a certain thickness into the bottom of the sleeve rod 102 of the base 10, and the outer diameter of the sleeve rod 102 is Φ4.0mm;

[0062] S3. See Figure 5 , put the Φ4.5×4.0×4mm inner low-melting-point metal layer 12, Φ7.5×4.5×4mm piezoelectric element 13, Φ8.0×7.5×4mm outer low-melting-point metal around the sleeve rod 102 on the jig 11 layer 18, and then put the Φ12.5×8.0×5.5mm mass block 14 into the sleeve rod, so that the inner low melting point metal layer 12, the piezoelectric element 13, and the outer low melting point metal layer 18 are sandwiched...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com