Vertical transition structure

A vertical transition, ground plane technology, used in fixed connections, printed circuit components, electrical components, etc., can solve the problems of not meeting the high-performance transmission requirements of millimeter-wave, poor transmission performance in the millimeter-wave frequency band, and large application limitations, and achieve reliable performance. High performance, wide operating frequency, and the effect of increasing the area of the welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

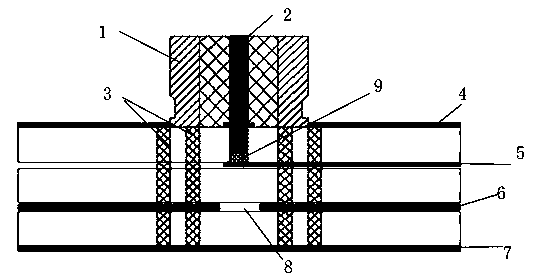

[0017] Such as image 3 Shown is a schematic diagram of the vertical transition structure involved in the present invention. Including radio frequency coaxial connector 1, microwave multilayer printed board.

[0018] The microwave multilayer printed board is respectively a first ground plane 4 , a stripline layer 5 , a second ground plane 6 and a third ground plane 7 from top to bottom.

[0019] A vertical transition blind hole 9 is arranged between the first ground plane 4 and the stripline layer 5; the radio frequency coaxial connector 1 is arranged on the first ground plane 4, and the outer conductor of the radio frequency coaxial connector 1 is connected to the first ground plane 4 Welding to form an electrical connection, where the inner conductor 2 grows appropriately, extends downwards into the vertical transition blind hole 9 and does not exceed the depth of the vertical transition blind hole 9, and welds to form an electrical connection. Since the radio frequency co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com