Feed additive for laying hens, preparation method of feed additive and laying hen feed

A technology of laying hen feed and additives, which is applied in the field of laying hen feed, can solve problems such as cost reduction, and achieve the effects of cost reduction, good detoxification, and improvement of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 prepares feed additive

[0042] (1) First fermentation

[0043] 1) Prepare the first mixed bacterial solution

[0044] The stock solutions of Aspergillus niger, Trichoderma viride and Candida utilis were prepared in a ratio of 1:1:1 to prepare the first mixed bacterial solution.

[0045] 2) Prepare the first fermentation substrate

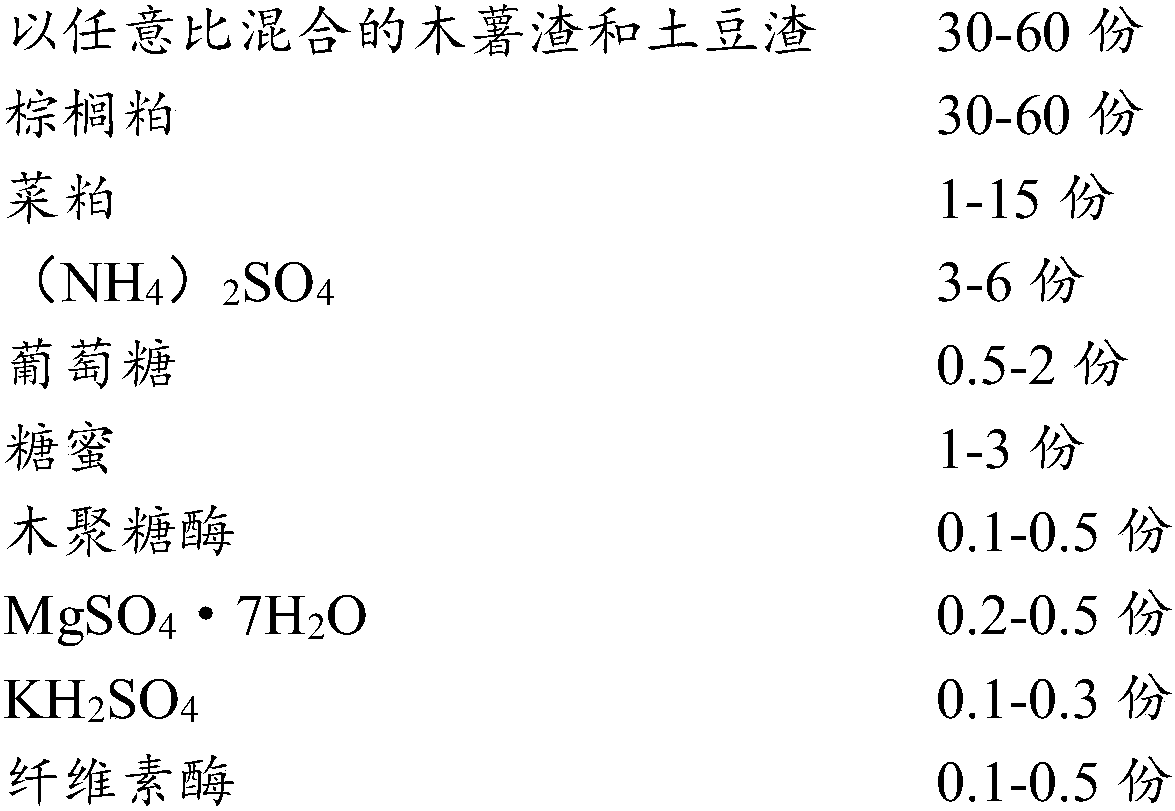

[0046]

[0047]

[0048] Among them, the crude protein content of cassava dregs and potato dregs is about 5-2.5%, the starch content > 30%, and the water content < 80%; the crude protein content of palm is 16.5-20%, and the cellulose content is 12-14%; The crude protein content of rapeseed meal is about 36%.

[0049] 3) First fermentation

[0050] After mixing the above-mentioned fermentation raw materials, adjust the water content to 70%, pH 5, and ferment at a constant temperature of 35°C for 48-54 hours. The fermented product is dried and sterilized to obtain the first fermented product. It is tested that the crude...

Embodiment 2

[0064] Embodiment 2 prepares laying hen feed additive

[0065] (1) First fermentation

[0066] 1) Prepare the first mixed bacterial solution

[0067] The stock solutions of Aspergillus niger, Trichoderma viride and Candida utilis were prepared in a ratio of 1:1:1 to prepare the first mixed bacterial solution.

[0068] 2) Prepare the first fermentation substrate

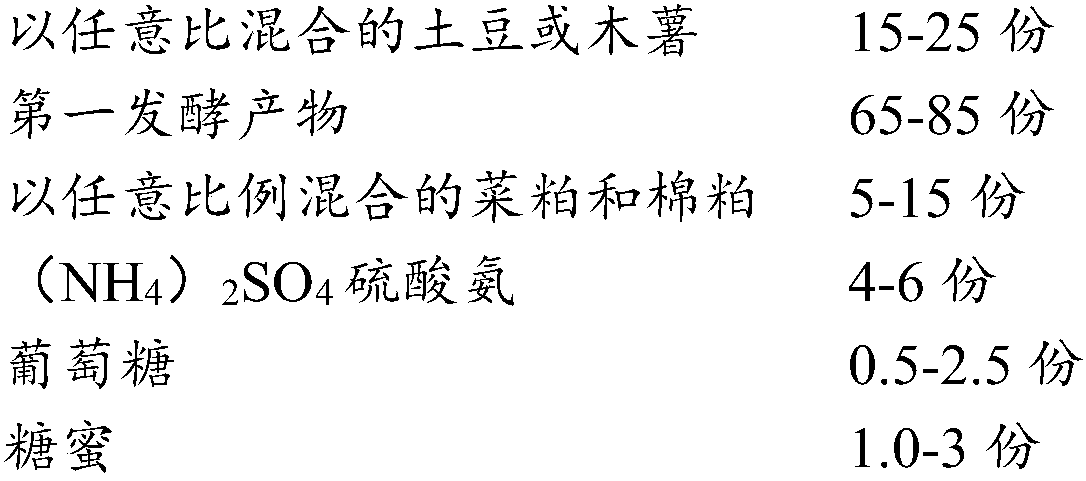

[0069]

[0070] Among them, the crude protein content of cassava dregs and potato dregs is about 5-2.5%, the starch content > 30%, and the water content < 80%; the crude protein content of palm is 16.5-20%, and the cellulose content is 12-14%. ; The crude protein content of rapeseed meal is about 36%.

[0071] 3) First fermentation

[0072] After mixing the above fermentation raw materials, adjust the water content to 60-80%, preferably the optimum water content is 70%, pH5, and ferment at a constant temperature of 35°C for 48-54 hours. The fermented product is dried and sterilized to obtain the first fermente...

Embodiment 3

[0087] Embodiment 3 prepares laying hen feed additive

[0088] (1) First fermentation

[0089] 1) Prepare the first mixed bacterial solution

[0090] The stock solution of Aspergillus niger, Trichoderma viride and Saccharomyces cerevisiae was prepared in a ratio of 1:1:1 to prepare the first mixed bacterial solution.

[0091] 2) Prepare the first fermentation substrate

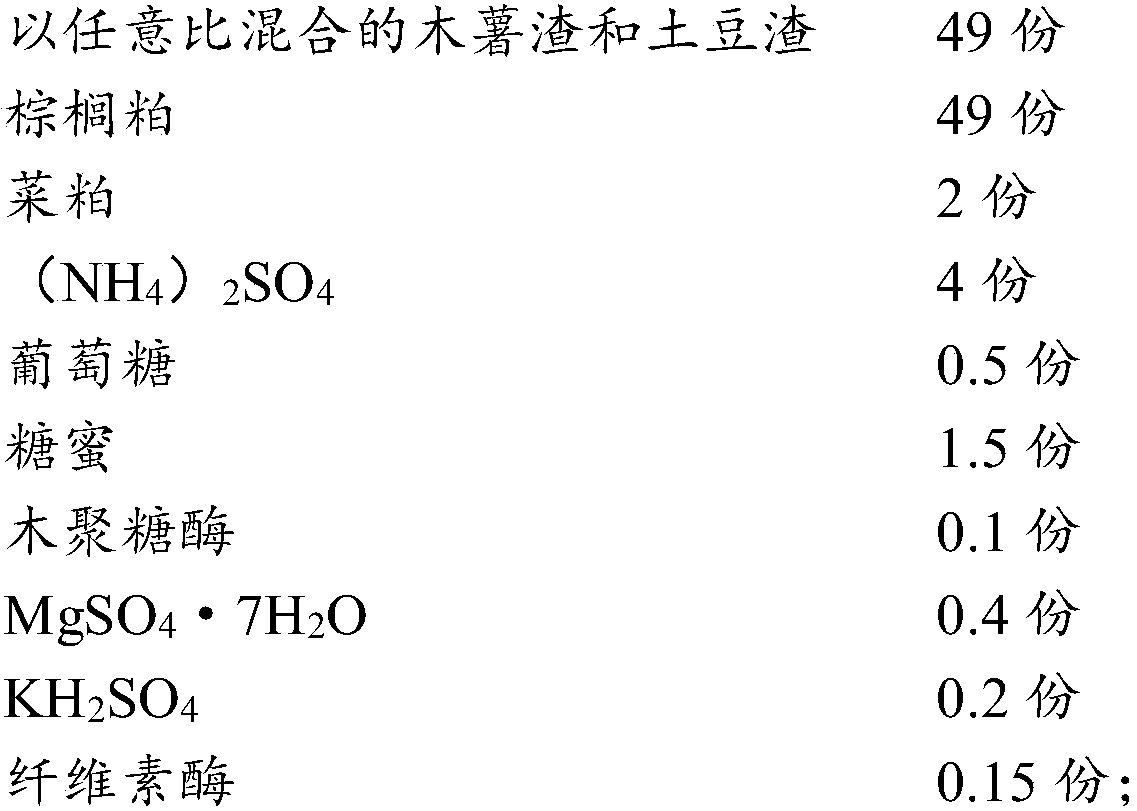

[0092]

[0093]

[0094] Among them, the crude protein content of cassava dregs and potato dregs is about 5-2.5%, the starch content > 30%, and the water content < 80%; the crude protein content of palm is 16.5-20%, and the cellulose content is 12-14%; The crude protein content of rapeseed meal is about 36%.

[0095] 3) First fermentation

[0096] After mixing the above-mentioned fermentation raw materials, adjust the water content to 60%, pH 5, and ferment at a constant temperature of 35°C for 48-54 hours. The fermented product is dried and sterilized to obtain the first fermented product. It is te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com