Algae oil microcapsules as well as preparation method and application thereof

A technology of microcapsules and algae oil, which is applied in microcapsules, applications, and capsule transportation, etc., which can solve the problems of easy oxidation, high oil content and embedding rate of algae oil microcapsules, high operating costs and high production costs problems, to achieve the effects of maintaining stability, promoting development and utilization, increasing oil content and embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

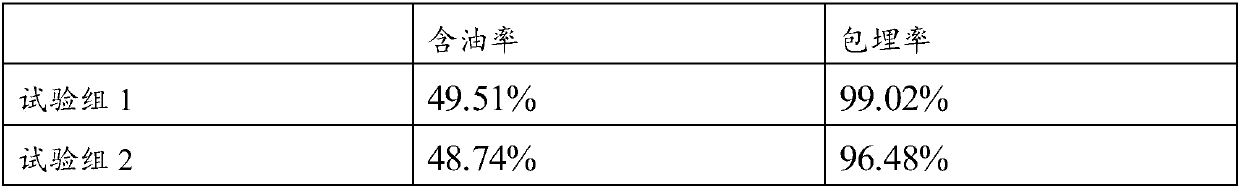

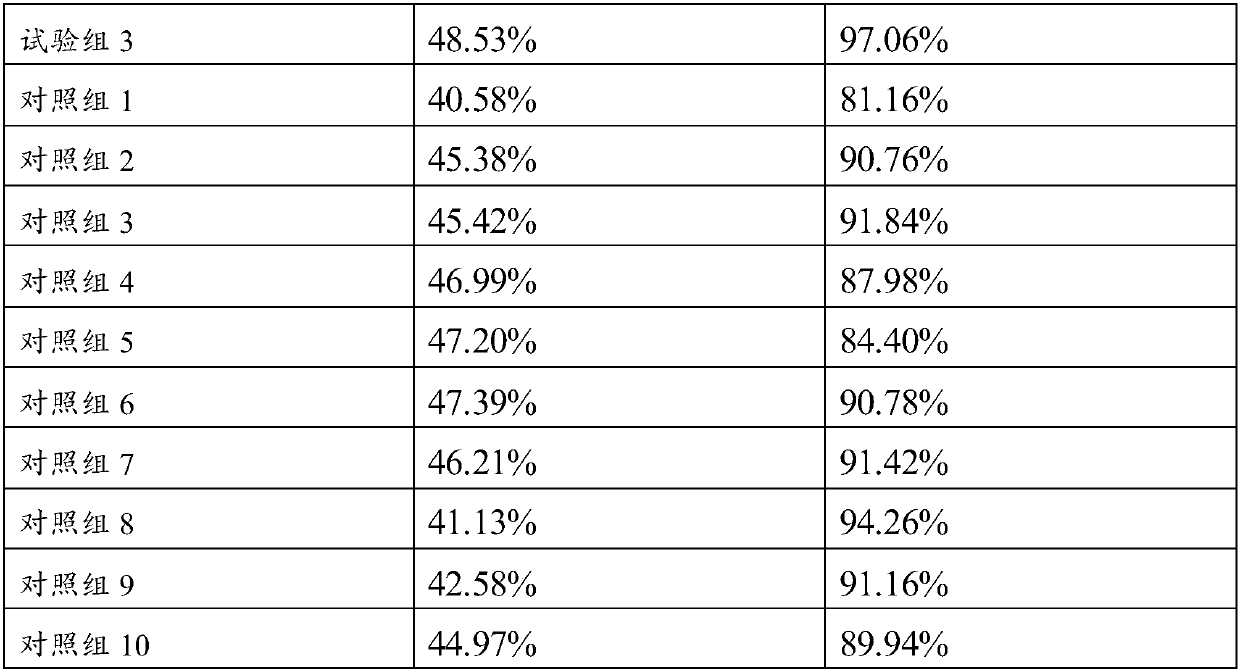

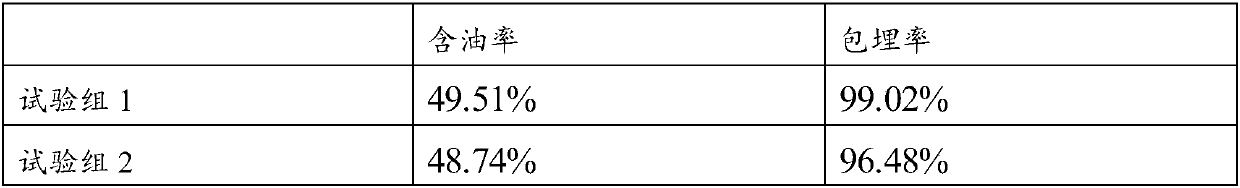

Embodiment 1

[0034] Embodiment 1: Preparation of algae oil microcapsules of the present invention

[0035] 1. Raw material components

[0036] 22.5 parts of algae oil, 7.5 parts of maltodextrin (DE20), 14 parts of octenyl succinic esterified starch HI-CAP100, 0.068 parts of monoglyceride, 0.0135 parts of vitamin E and 0.0036 parts of vitamin C palmitate.

[0037] 2. Preparation method

[0038] Weigh HI-CAP100 and maltodextrin (DE20) and mix evenly, add 500g of deionized water at 60°C, stir at 60°C at 300r / min until completely dissolved and uniform, and prepare an aqueous phase liquid;

[0039] Then weigh algae oil and place it in another container, stir at 300r / min at 60°C, then weigh monoglyceride, VE and VC palmitate and add it, continue to keep warm and stir until completely dissolved, and prepare an oil phase liquid ;

[0040] Slowly add the oil phase to the water phase liquid, and keep stirring at 60°C for 10 minutes, then emulsify twice at 12000r / min high-speed shear, 10 minutes e...

Embodiment 2

[0042] Embodiment 2: Preparation of algae oil microcapsules of the present invention

[0043] 1. Raw material components

[0044] 22.5 parts of algae oil, 3.73 parts of maltodextrin (DE10), 18.7 parts of octenyl succinic esterified starch HI-CAP100, 0.068 parts of monoglyceride, 0.0135 parts of vitamin E and 0.0036 parts of vitamin C palmitate.

[0045] 2. Preparation method

[0046] Weigh HI-CAP100 and maltodextrin (DE10) and mix evenly, add 500g of deionized water at 60°C, stir at 60°C at 300r / min until completely dissolved, and prepare an aqueous phase liquid;

[0047] Then weigh algae oil and place it in another container, stir at 300r / min at 60°C, then weigh monoglyceride, VE and VC palmitate and add it, continue to keep warm and stir until completely dissolved, and prepare an oil phase liquid ;

[0048] Slowly add the oil phase to the water phase liquid, and keep stirring at 60°C for 10 minutes, then emulsify twice at 12000r / min high-speed shear, 10 minutes each time, t...

Embodiment 3

[0050] Embodiment 3: Preparation of algae oil microcapsules of the present invention

[0051] 1. Raw material components

[0052] 22.5 parts of algae oil, 4.5 parts of maltodextrin (DE15), 17.9 parts of octenyl succinic esterified starch HI-CAP100, 0.068 parts of monoglyceride, 0.0135 parts of vitamin E and 0.0036 parts of vitamin C palmitate.

[0053] 2. Preparation method

[0054] Weigh HI-CAP100 and maltodextrin (DE15) and mix evenly, add 500g of deionized water at 60°C, stir at 60°C at 300r / min until completely dissolved and uniform, and prepare an aqueous phase liquid;

[0055] Then weigh algae oil and place it in another container, stir at 300r / min at 60°C, then weigh monoglyceride, VE and VC palmitate and add it, continue to keep warm and stir until completely dissolved, and prepare an oil phase liquid ;

[0056] Slowly add the oil phase to the water phase liquid, and keep stirring at 60°C for 10 minutes, then emulsify twice at 12000r / min high-speed shear, 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com