Thermal management system of power battery pack and electric automobile with system

A technology of a power battery pack and a thermal management system, applied in the field of electric vehicles, can solve the problems of uneven heating of the power battery pack, large temperature difference of the power battery module, and increased power consumption of the electric vehicle, so as to achieve reasonable energy distribution of the whole vehicle, Good temperature uniformity and temperature stability, and the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

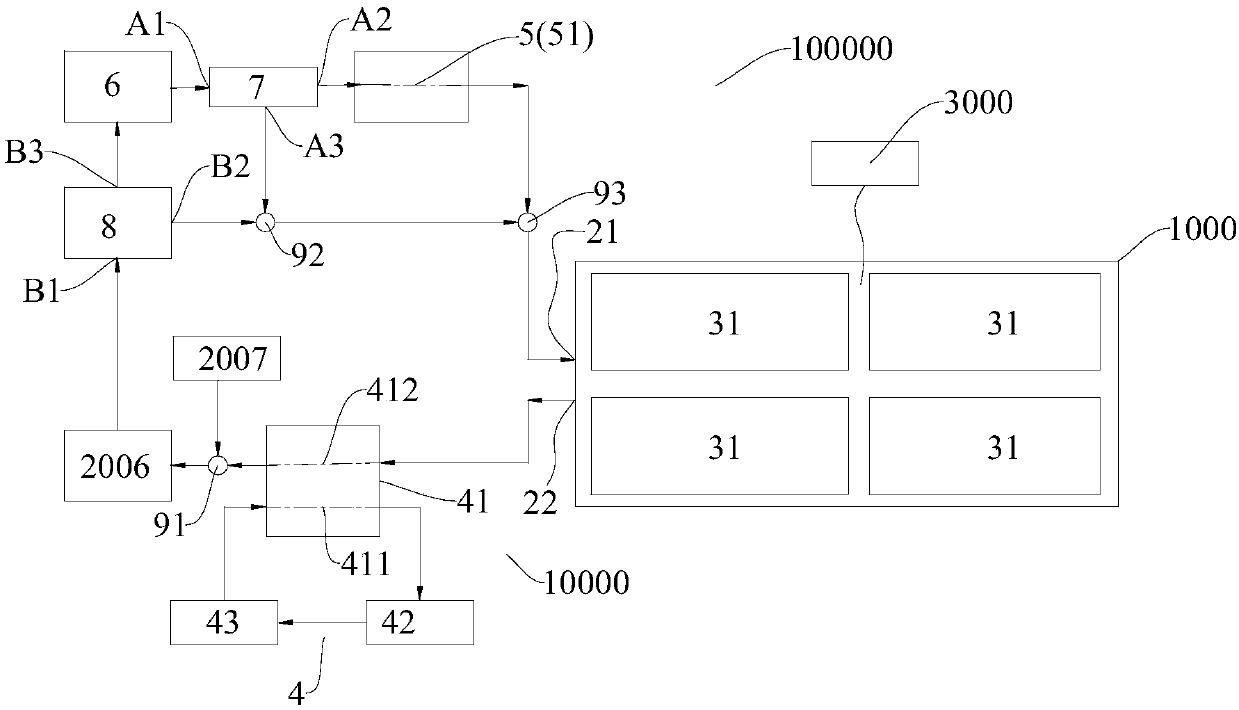

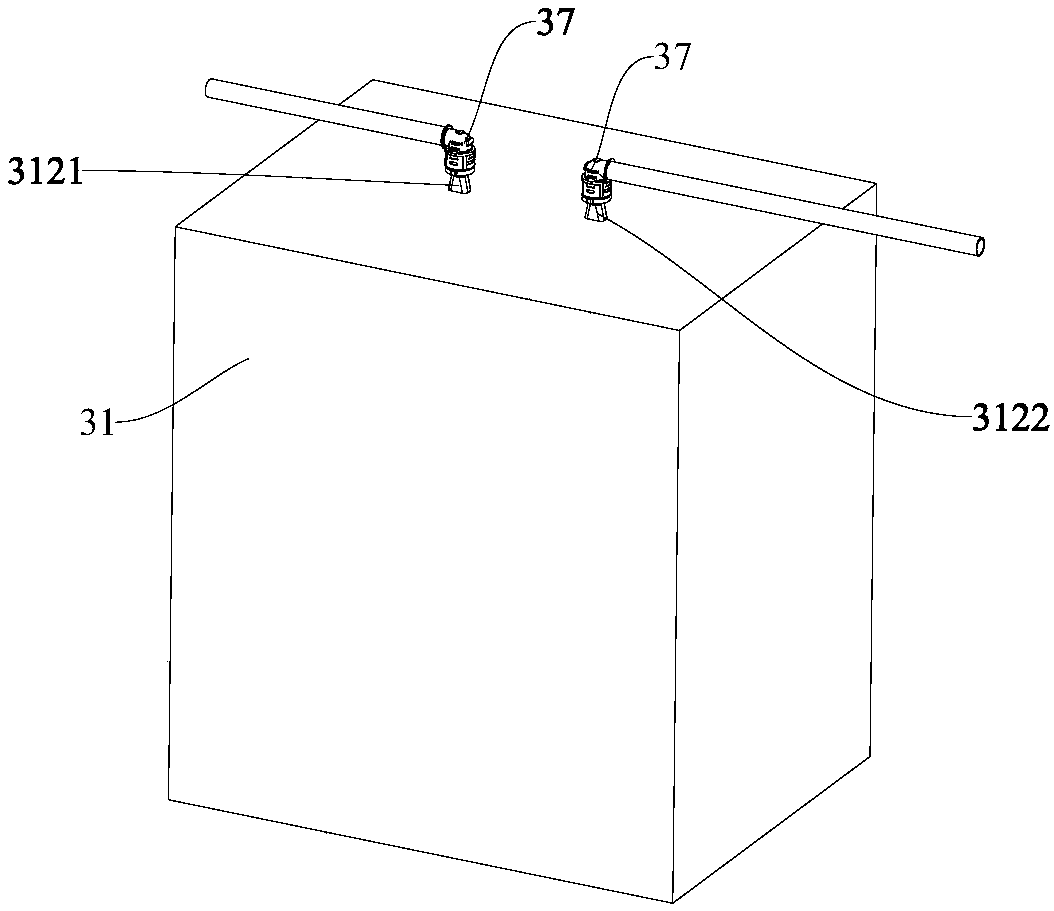

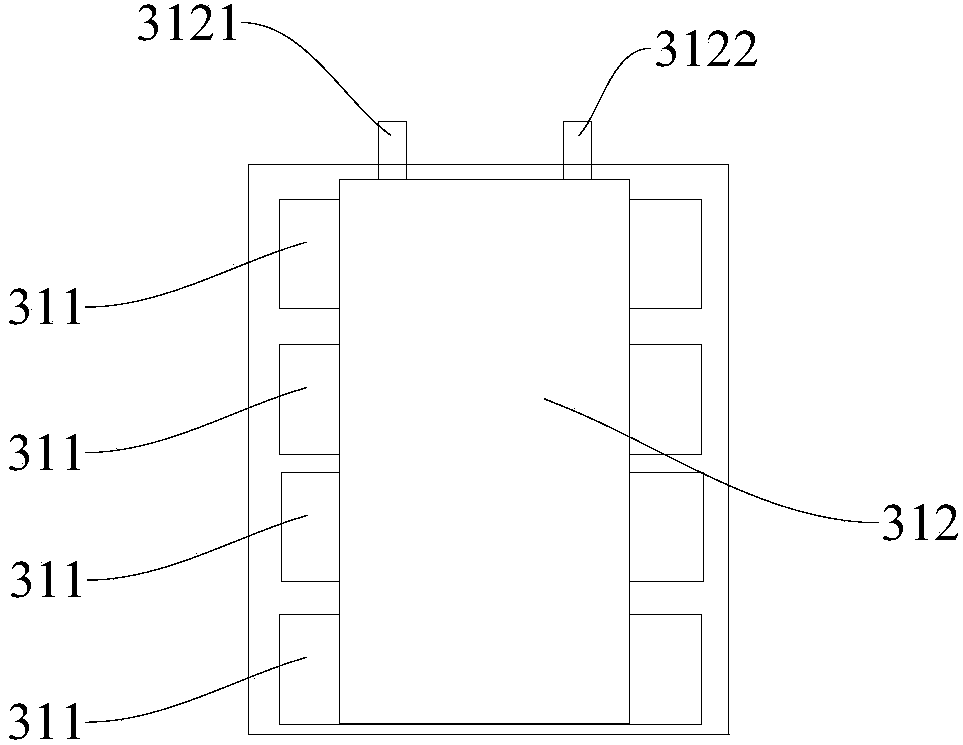

[0022] Refer below Figure 1-Figure 10 The thermal management system 10000 of the power battery pack according to the embodiment of the present invention will be described in detail. like Figure 1-Figure 10 As shown, the thermal management system 10000 of a power battery pack according to an embodiment of the present invention includes a power battery pack 1000 , a heat exchange circulation pipeline, an air conditioning system of an electric vehicle 100000 and a first PTC heater 6 .

[0023] The power battery pack 1000 can be installed on an electric vehicle to provide power output for the electric vehicle and an energy storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com