Tungsten bronze pure-phase room-temperature multiferroic ceramic and preparation method thereof

A room temperature multiferroic and multiferroic ceramic technology, applied in the field of tungsten bronze pure-phase room temperature multiferroic ceramics and its preparation, can solve the problems of poor ferromagnetism, unfavorable improvement of ferromagnetism, and difficulty in obtaining pure equivalence. To achieve the effect of short sintering time, low cost, uniform and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Chemical composition expression Ba 4 SM 2 Fe 2 Nb 8 o 30 (BSFN). with BaCO 3 、Sm 2 o 3 , Nb 2 o 5 , Fe 2 o 3 Electronic-grade powder is the raw material for preparing ceramics. The ingredients are weighed according to the molecular formula, and they are milled with high-energy balls in deionized water for 4 hours. After drying, they are heated at 1150 o C for 4 hours to synthesize tungsten bronze single-phase BSFN powder; the BSFN powder was again high-energy ball milled in deionized water for 2 hours, after drying, 1wt% polyvinyl alcohol binder was added for granulation, and the granulated powder The body was pressed into a BSFN green body under 100MPa. After debinding the BSFN body, at 1250 o C microwave sintering method (2.45GHz) heat preservation for 30 minutes, then cool to room temperature with the furnace.

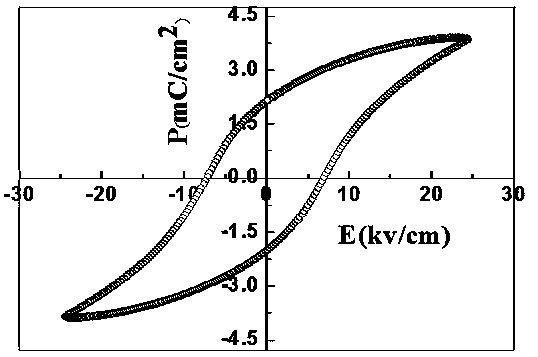

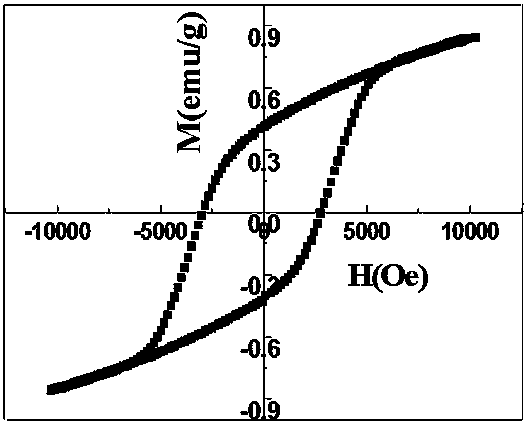

[0023] The obtained BSFN multiferroic single-phase ceramics has a tungsten bronze crystal structure and a microstructure composed of equiaxed g...

Embodiment 2

[0025] Chemical composition expression Ba 4 SM 2 Fe 2 Nb 8 o 30 (BSFN). with BaCO 3 、Sm 2 o 3 , Nb 2 o 5 , Fe 2 o 3 Electronic-grade powder is the raw material for preparing ceramics. The ingredients are weighed according to the molecular formula, and they are high-energy ball milled in alcohol for 6 hours. After drying, they are heated at 1150 o C for 2 hours to synthesize tungsten bronze single-phase BSFN powder; the BSFN powder was again high-energy ball milled in alcohol for 2 hours, after drying, 1wt% polyvinyl alcohol binder was added for granulation, and the granulated powder was Pressed into BSFN body under 150MPa. After debinding the BSFN body, at 1250 o C microwave sintering method (2.45GHz) heat preservation for 30 minutes, then cool to room temperature with the furnace.

[0026] The obtained BSFN multiferroic single-phase ceramics has a tungsten bronze crystal structure and a microstructure composed of equiaxed grains with a size not exceeding 2 micro...

Embodiment 3

[0028] Chemical composition expression Ba 4 SM 2 Fe 2 Nb 8 o 30 (BSFN). with BaCO 3 、Sm 2 o 3 , Nb 2 o 5 , Fe 2 o 3 The electronic grade powder is the raw material for preparing ceramics. The ingredients are weighed according to the molecular formula, and the high-energy ball milling in deionized water is carried out for 16 hours. o C for 4 hours to synthesize tungsten bronze single-phase BSFN powder; the BSFN powder was again high-energy ball milled in deionized water for 4 hours, after drying, 1wt% polyvinyl alcohol binder was added for granulation, and the granulated powder was The body was pressed into a BSFN green body under 100MPa. After debinding the BSFN body, at 1250 o C Microwave sintering method (2.45GHz) heat preservation for 15 minutes, and cool to room temperature with the furnace. The obtained BSFN multiferroic single-phase ceramics has a tungsten bronze crystal structure and a microstructure composed of equiaxed grains with a size not exceeding 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com