Pipe joint

A technology for pipe joints and aluminum alloys, applied in the field of pipe joints, can solve the problems of complex aluminum alloys, lack of precision, and insufficient strength, etc., to achieve the effect of weakening the supercooling of components, simple methods, and exacerbating shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

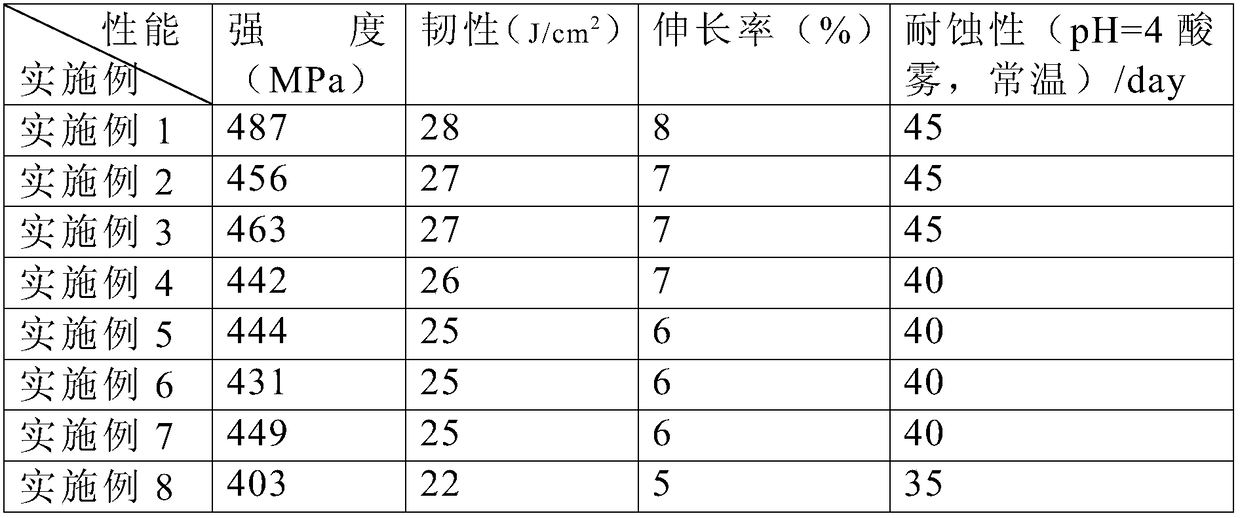

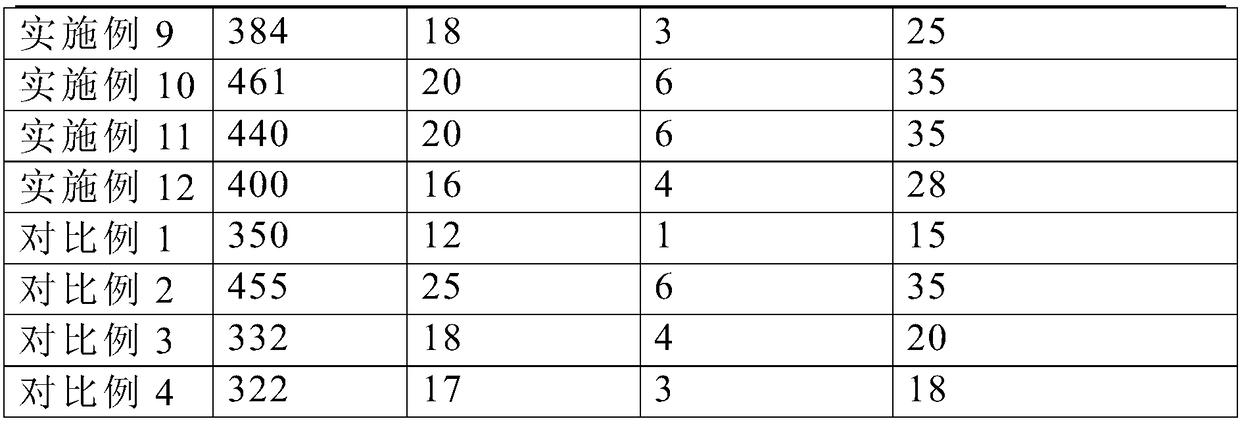

Examples

Embodiment 1

[0029] Ingredients: weighed according to aluminum alloy raw materials, Mg: 0.07%, Mn: 0.12%, Ni: 0.15%, composite carbon: 0.12%, Zn: 0.03%, the balance is Al and impurities, and the composite carbon is composed of C 60 、C 70 , carbon microbeads, single-walled carbon nanotubes and carbon nanomaterials;

[0030] Alloy smelting: weighing the aluminum alloy raw material according to claim 1, mixing and melting all materials except composite carbon to form alloy liquid, adding carbon nanomaterials into chloroform, placing them in a hot water bath, and conducting nanoscale detection Needle ultrasonic crushing treatment, then pour into an open vessel at room temperature to volatilize the solvent to obtain composite carbon powder;

[0031] Refining: Lay the composite carbon powder evenly in the pipe joint mold, pour the alloy liquid into the mold through the curved channel, and cool to form the semi-finished pipe joint. And add a magnetic field outside the curved channel, the magnet...

Embodiment 2

[0034] Ingredients: weighed according to aluminum alloy raw materials, Mg: 0.05%, Mn: 0.09%, Ni: 0.12%, composite carbon: 0.07%, Zn: 0.02%, the balance is Al and impurities, and the composite carbon is composed of C 60 、C 70 Made of carbon nanomaterials;

[0035] Alloy smelting: weighing the aluminum alloy raw material according to claim 1, mixing and melting all materials except composite carbon to form alloy liquid, adding carbon nanomaterials into chloroform, placing them in a hot water bath, and conducting nanoscale detection Needle ultrasonic crushing treatment, then pour into an open vessel at room temperature to volatilize the solvent to obtain composite carbon powder;

[0036] Refining: Lay the composite carbon powder evenly in the pipe joint mold, pour the alloy liquid into the mold through the curved channel, and cool to form the semi-finished pipe joint. And add a magnetic field outside the curved channel, the magnetic field will rotate around the curved channel a...

Embodiment 3

[0039] Ingredients: weighed according to aluminum alloy raw materials, Mg: 0.1%, Mn: 0.15%, Ni: 0.18%, composite carbon: 0.17%, Zn: 0.04%, the balance is Al and impurities, and the composite carbon is composed of C 60 , Single-walled carbon nanotubes and carbon nanomaterials compounded;

[0040] Alloy smelting: weighing the aluminum alloy raw material according to claim 1, mixing and melting all materials except composite carbon to form alloy liquid, adding carbon nanomaterials into chloroform, placing them in a hot water bath, and conducting nanoscale detection Needle ultrasonic crushing treatment, then pour into an open vessel at room temperature to volatilize the solvent to obtain composite carbon powder;

[0041] Refining: Lay the composite carbon powder evenly in the pipe joint mold, pour the alloy liquid into the mold through the curved channel, and cool to form the semi-finished pipe joint. And add a magnetic field outside the curved channel, the magnetic field will ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com