An osteoinductive dental implant

A dental implant and osteoinduction technology, which can be used in dental implants, dentistry, dental prosthetics, etc., can solve the problems of insufficient induction ability and stability, weak self-tapping ability, and inability to shorten the operation time, so as to shorten the implant operation time. , the effect of shortening the biocompatibility and accelerating the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

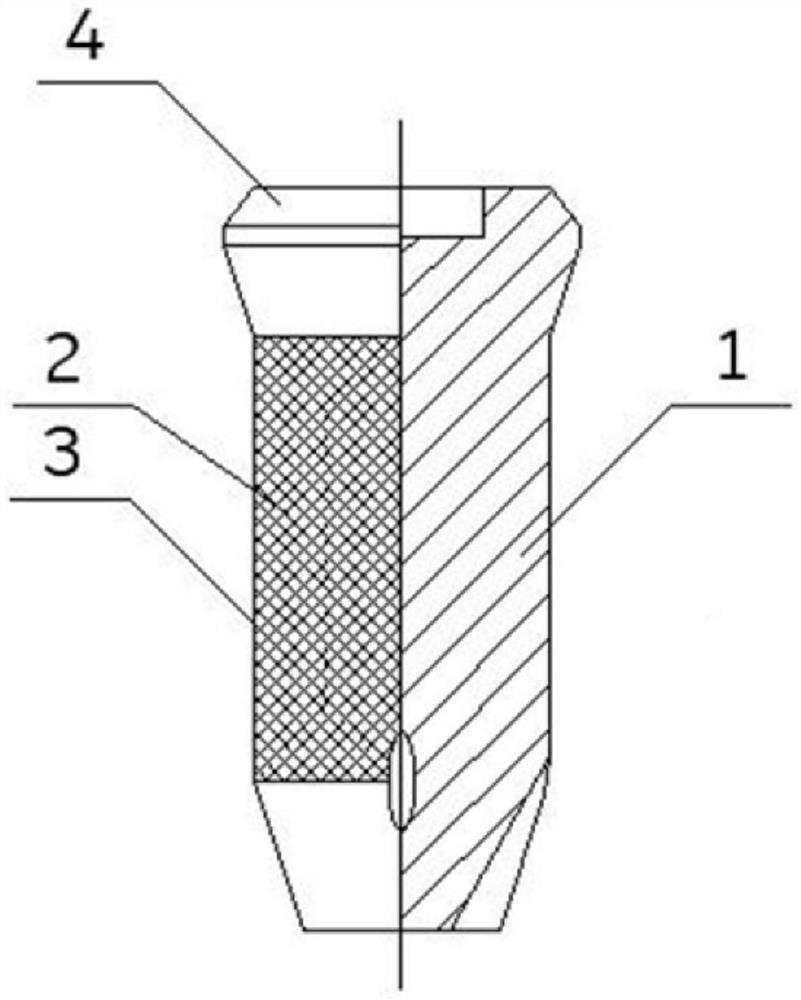

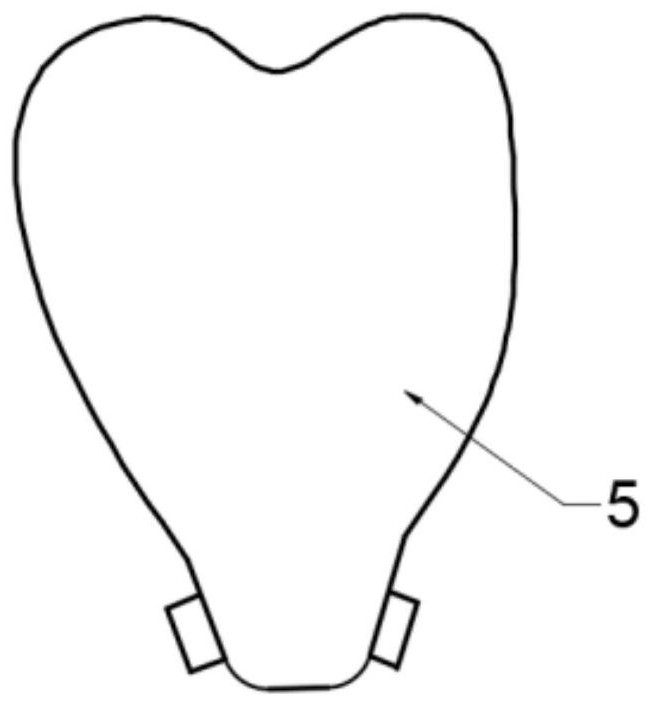

[0028] Please refer to the attached Figure 1-3 , the purpose of this embodiment is to provide a dental implant with an osteoinductive structure, comprising: a solid part 1, a trabecular bone part 2 and a tantalum coating part 3; the solid part 1 has a top and a root, and the top of the solid part 1 The abutment part 4 is integrally formed; the total length from the top to the root of the solid part 1 is 6 mm, the diameter of the cylindrical part of the solid part 1 is 5 mm, and the conical diameter of the root of the solid part 1 is 3 mm. Preferably, the diameter of the abutment part 4 is larger than the diameter of the solid part 1, and the inconsistency between the two diameters can realize stress transfer and avoid stress concentration.

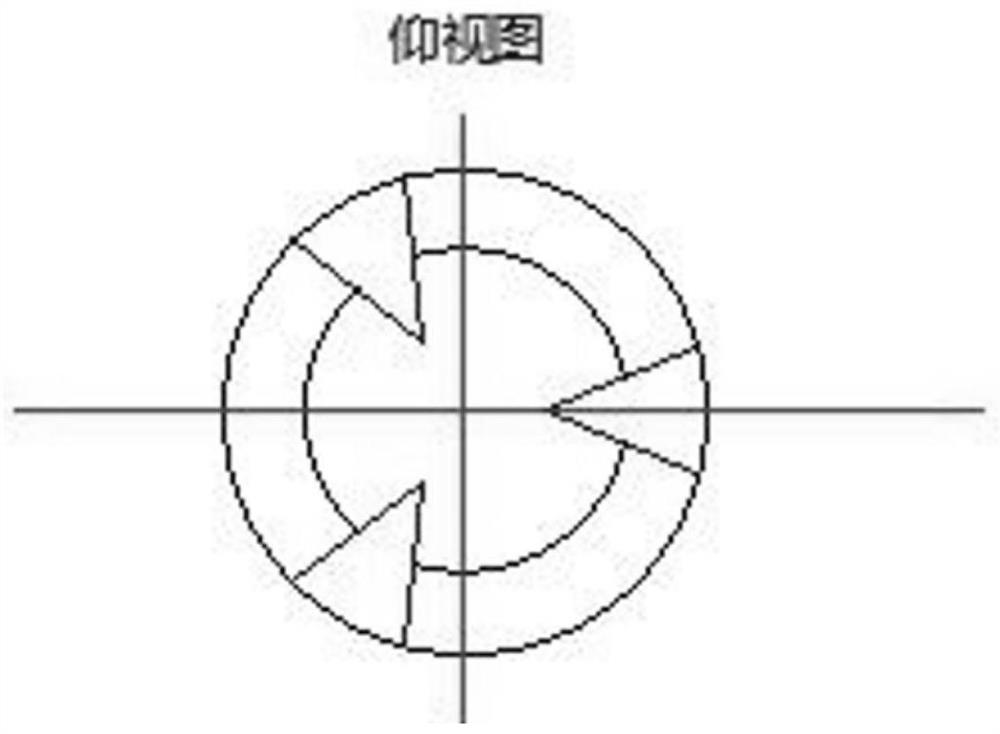

[0029] Specifically, the root of the solid part 1 is conical threaded and has a conical band structure. The root is not only a threaded structure, but the conical band is provided with three cutting edges. The screwing in has a self-tappi...

Embodiment 2

[0034] Please refer to the attached Figure 1-3 , the purpose of this embodiment is to provide a dental implant with an osteoinductive structure, comprising: a solid part 1, a trabecular bone part 2 and a tantalum coating part 3; the solid part 1 has a top and a root, and the top of the solid part 1 The abutment part 4 is integrally formed; the total length from the top to the root of the solid part 1 is 20 mm, the diameter of the cylindrical part of the solid part 1 is 8 mm, and the conical diameter of the root of the solid part 1 is 3-5 mm. Preferably, the diameter of the abutment part 4 is larger than the diameter of the solid part 1, and the inconsistency between the two diameters can realize stress transfer and avoid stress concentration.

[0035] Specifically, the root of the solid part 1 is conical threaded and has a conical band structure. The root is not only a threaded structure, but the conical band is provided with three cutting edges. The screwing in has a self-ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com