Nitrile butadiene rubber reinforcement type plasticizer preparation method

A technology of rubber reinforcing agent and nitrile rubber, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve problems such as easy precipitation and no reinforcing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

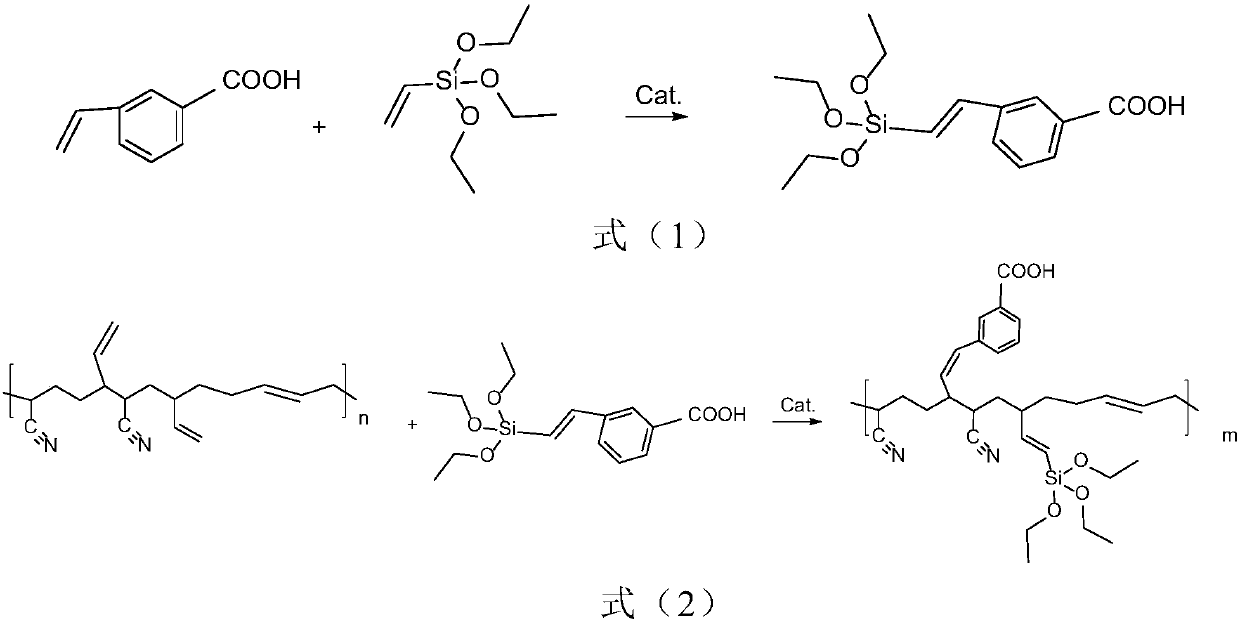

Method used

Image

Examples

Embodiment 1

[0037] Mix anti-scorch agent 2-vinyl benzoic acid and reinforcing agent nitrile vinyl triethoxysilane at a molar ratio of 1.0:5.0, prepare a solution with a mass concentration of 30% with hexane solvent, and add anti-scorch to the solution Olefin metathesis catalysts at 0.1% of the total amount of coking agent and reinforcing agent Air and water were isolated, and after reacting at room temperature for 8 hours, the solvent was removed by a vacuum desolventizer to obtain anti-scorch rubber reinforcing agent 1-1.

[0038] Dissolve nitrile rubber NBR3305 in chloroform solvent to prepare a 0.11% concentration solution, add 0.51 parts of olefin metathesis catalyst and 11 parts of anti-scorch rubber reinforcing agent 1-1, and reacted for 0.5 hours at 15°C without air and water. After the reaction, the glue solution was removed by solvent to obtain a reinforced plasticizer product with an Mn of 7800.

[0039] Add 10 parts of this reinforcing plasticizer to nitrile rubber NBR3305 o...

Embodiment 2

[0044] Mix anti-scorch agent 3-vinylphthalic acid and reinforcing agent vinyldiethoxymethylsilane at a molar ratio of 1.0:0.1, prepare a solution with 1% mass concentration with hexane solvent, add to the solution Olefin metathesis catalysts accounting for 0.01% of the total amount of anti-scorch agents and reinforcing agents After isolating air and water and reacting at room temperature for 0.5 h, the solvent was removed by a vacuum desolventizer to obtain anti-scorch rubber reinforcing agent 2-1.

[0045] Dissolve nitrile rubber NBR3305 in acetone solvent to prepare a 10% concentration solution, add 1 part of olefin metathesis catalyst and 50 parts of anti-scorch rubber reinforcing agent 2-1, and react for 5 hours at 50°C in isolation from air and water. The reacted glue solution is detached by solvent to obtain a reinforced plasticizer product with Mn of 3000.

[0046] Add 10 parts of the plasticizer to the nitrile rubber NBR3305 on the mill. After testing, the Mooney vi...

Embodiment 3

[0052] Mix anti-scorch agent 3-vinyl phthalic anhydride and reinforcing agent vinyl trimethoxysilane at a molar ratio of 1.0:4.0, prepare a solution with 10% mass concentration with hexane solvent, add Zhan Fang to the solution Olefin Metathesis Catalysts 0.09% of the Total Substance Amount of Coke and Reinforcing Agents Isolate air and water, react at room temperature for 4.5 hours, and use a vacuum desolventizer to remove the solvent to obtain anti-scorch rubber reinforcing agent 3-1.

[0053] The nitrile rubber NBR2907 base rubber is dissolved in chlorobenzene solvent to prepare a 19% concentration solution, and 1.4 parts of olefin metathesis catalyst are added and 25 parts of anti-scorch rubber reinforcing agent 3-1, and react for 2.5 hours at 25°C without air and water.

[0054] Add 30 parts of the plasticizer to the nitrile rubber NBR2907 on the mill. After testing, the Mooney viscosity decreased from 75 to 40, the tensile strength increased from 24.3MPa to 27.5MPa, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com