Easily-processed and reinforced nitrile butadiene rubber preparation method

A nitrile-butadiene rubber and easy-to-process technology, applied in the field of nitrile-butadiene rubber preparation, can solve the problems of no reinforcement effect, easy precipitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

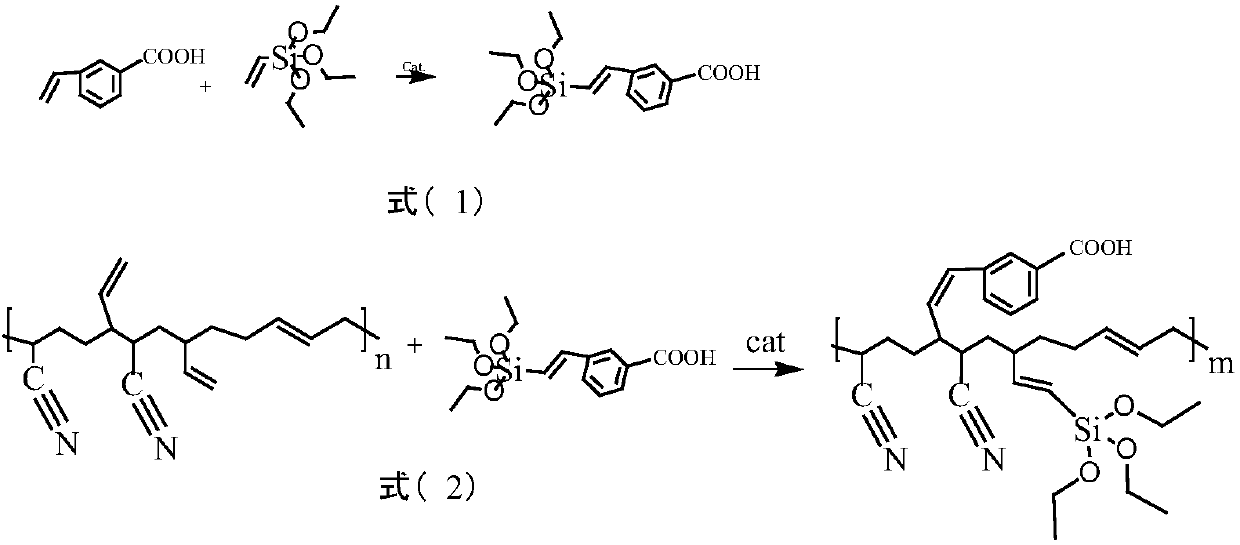

Method used

Image

Examples

Embodiment 1

[0044] Mix anti-scorch agent 2-vinyl benzoic acid and reinforcing agent nitrile vinyl triethoxysilane at a molar ratio of 1.0:5.0, prepare a solution with a mass concentration of 30% with hexane solvent, and add anti-scorch to the solution Olefin metathesis catalysts at 0.1% of the total amount of coking agent and reinforcing agent Air and water were isolated, and after reacting at room temperature for 8 hours, the solvent was removed by a vacuum desolventizer to obtain anti-scorch rubber reinforcing agent 1-1.

[0045] Dissolve nitrile rubber NBR3305 in chloroform solvent to prepare a 1.5%w solution, add 0.53 parts of olefin metathesis catalyst in 100 parts by mass of rubber and 19 parts of anti-scorch rubber reinforcing agent 1-1, isolated from air and water at 15.5°C, reacted for 0.53 hours, and the reacted glue solution was removed by solvent to obtain a reinforced plasticizer product with Mn of 2800;

[0046] Add 100 parts of the prepared reinforced plasticizer product...

Embodiment 2

[0055] Mix anti-scorch agent 3-vinylphthalic acid and reinforcing agent vinyldiethoxymethylsilane at a molar ratio of 1.0:0.1, prepare a solution with 1% mass concentration with hexane solvent, add to the solution Olefin metathesis catalysts accounting for 0.01% of the total amount of anti-scorch agents and reinforcing agents After isolating air and water and reacting at room temperature for 0.5 h, the solvent was removed by a vacuum desolventizer to obtain anti-scorch rubber reinforcing agent 2-1.

[0056] Dissolve nitrile rubber NBR3305 in acetone solvent to prepare a 10%w solution, add 0.98 parts of olefin metathesis catalyst to 100 parts by mass of rubber and 48 parts of anti-scorch rubber reinforcing agent 2-1, isolated from air and water at 48.9°C, and reacted for 4.5 hours. After the reaction, the glue solution was removed by solvent to obtain a reinforcing plasticizer product with Mn of 3200;

[0057] Add 100 parts of the prepared reinforced plasticizer product, 19 ...

Embodiment 3

[0067] Mix the anti-scorch agent 3-vinylphthalic acid and the reinforcing agent vinyltrimethoxysilane at a molar ratio of 1.0:4.0, prepare a 10% mass concentration solution with hexane solvent, add anti-scorch 0.09% of the total substance amount of agent and reinforcing agent for olefin metathesis catalyst Isolate air and water, react at room temperature for 4.5 hours, and use a vacuum desolventizer to remove the solvent to obtain anti-scorch rubber reinforcing agent 3-1.

[0068] Dissolve nitrile rubber NBR2907 in chlorobenzene solvent to prepare a 5%w solution, add 0.54 parts of olefin metathesis catalyst based on 100 parts by mass of rubber and 25 parts of anti-scorch rubber reinforcing agent 3-1, isolated from air and water at 25°C, reacted for 2.5 hours, and the reacted glue solution was removed by solvent to obtain a reinforcing plasticizer product with Mn of 2400;

[0069] Add 100 parts of the prepared reinforced plasticizer product, 10 parts of emulsifier sodium abi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com