Disposal method of multi-metal coexistence hazardous wastes

A disposal method and technology for hazardous waste, applied in the direction of improving process efficiency, etc., can solve the problems of non-ferrous metal resource recycling, hidden dangers caused by secondary pollution, etc., and achieve resource recycling and environmental reduction. Harm, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

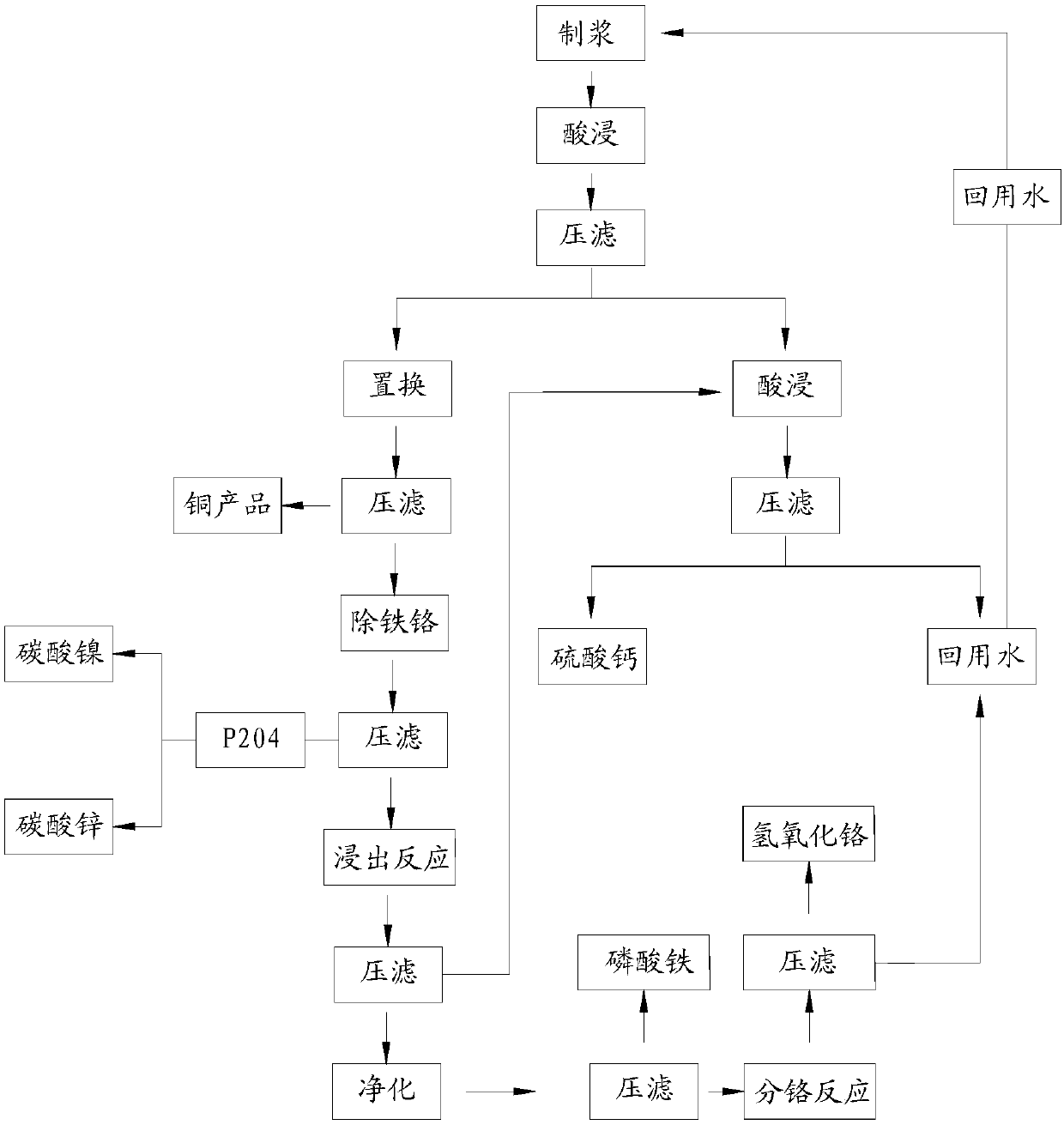

[0022] Such as figure 1 Shown, a kind of disposal method of polymetallic coexistence hazardous waste comprises the following steps:

[0023] First of all, the materials of polymetallic mixed hazardous waste (such as the mixture of HW17, etc.) are explained: because the phenomenon of coexistence of HW17 metal ions in hazardous waste is the most complicated, while HW21 / HW22 / HW23 / HW46 is relatively simple, so we use HW17 as an example) mixed with water according to the weight ratio of 1:3.5-5.5 to make a slurry, the temperature is controlled below 65 degrees (the specific temperature is adjusted according to the specific material of the reactor), and 98% concentrated sulfuric acid is added to the slurry , stirred until fully reacted, the pH value at the end point was controlled between 0.5-1, and the solid and liquid were separated to obtain leachate A and solid.

[0024] Then, extract Zn, Cu, Ni, Fe, Cr, and Ca in polymetallics sequentially from the leaching solution A and the ...

Embodiment 2

[0100] Such as figure 1 Shown, a kind of disposal method of polymetallic coexistence hazardous waste comprises the following steps:

[0101] First of all, the materials of polymetallic mixed hazardous waste (such as the mixture of HW17, etc.) are explained: because the phenomenon of coexistence of HW17 metal ions in hazardous waste is the most complicated, while HW21 / HW22 / HW23 / HW46 is relatively simple, so we use HW17 as an example) mixed with water according to the weight ratio of 1:3-5 to make a slurry, the temperature is controlled below 65 degrees (the specific temperature is adjusted according to the specific material of the reactor), and 98% concentrated sulfuric acid is added to the slurry , stirred until fully reacted, the pH value at the end point was controlled between 0.5-1, and the solid and liquid were separated to obtain leachate A and solid.

[0102] Then, extract Zn, Cu, Ni, Fe, Cr, and Ca in polymetallics sequentially from the leaching solution A and the soli...

Embodiment 3

[0177] Such as figure 1 Shown, a kind of disposal method of polymetallic coexistence hazardous waste comprises the following steps:

[0178] First of all, the materials of polymetallic mixed hazardous waste (such as the mixture of HW17, etc.) are explained: because the phenomenon of coexistence of HW17 metal ions in hazardous waste is the most complicated, while HW21 / HW22 / HW23 / HW46 is relatively simple, so we use HW17 as an example) mixed with water according to the weight ratio of 1:3.5-5.5 to make a slurry, the temperature is controlled below 65 degrees (the specific temperature is adjusted according to the specific material of the reactor), and 98% concentrated sulfuric acid is added to the slurry , stirred until fully reacted, the pH value at the end point was controlled between 0.5-1, and the solid and liquid were separated to obtain leachate A and solid.

[0179] Then, extract Zn, Cu, Ni, Fe, Cr, and Ca in polymetallics sequentially from the leaching solution A and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com