Deoxidizing piece for steel production and preparation method of deoxidizing piece

A technology of deoxidation block and deoxidizer, which is applied in the field of metallurgical industry, can solve the problems of slow diffusion deoxidation and poor deep deoxidation effect, and achieve the effects of low cost, environmental protection and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method includes the steps:

[0023] 1. Separate the waste mortar from silicon wafer cutting into solid and liquid, and dry the solid components to obtain deoxidizer.

[0024] 2. Prepare a pig iron block with multiple holes.

[0025] 3. Put the deoxidizer and the pig iron block into a ball mill to rotate together, so that the deoxidizer is filled in the hole column to obtain the deoxidizer block.

[0026] The preparation method of the deoxidizing block utilizes the waste mortar generated in the process of cutting the crystalline silicon to realize resource recycling and utilization, which is beneficial to environmental protection. The prepared deoxidation block can allow silicon carbide and silicon to enter the inside of molten steel for deep deoxidation. The deoxidation method has high efficiency, low cost and simple operation.

[0027] In a more preferred solution, calculated by weight percentage, the chemical composition of the deoxidizer is: 80% to 90% SiC, 5%...

Embodiment 1

[0032] First, the waste mortar for silicon wafer cutting is subjected to solid-liquid separation, and the solid components are dried to obtain a deoxidizer. In this embodiment, calculated by weight percentage, the chemical composition of the prepared deoxidizer is 87% SiC, 6% Si, and 5% SiO 2 , 2% Fe.

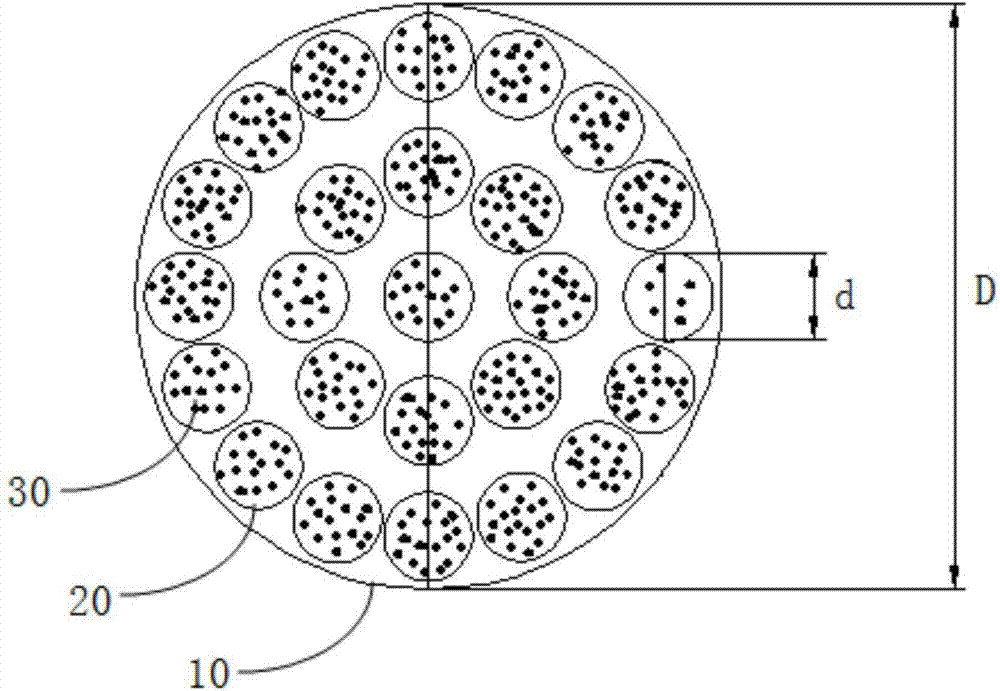

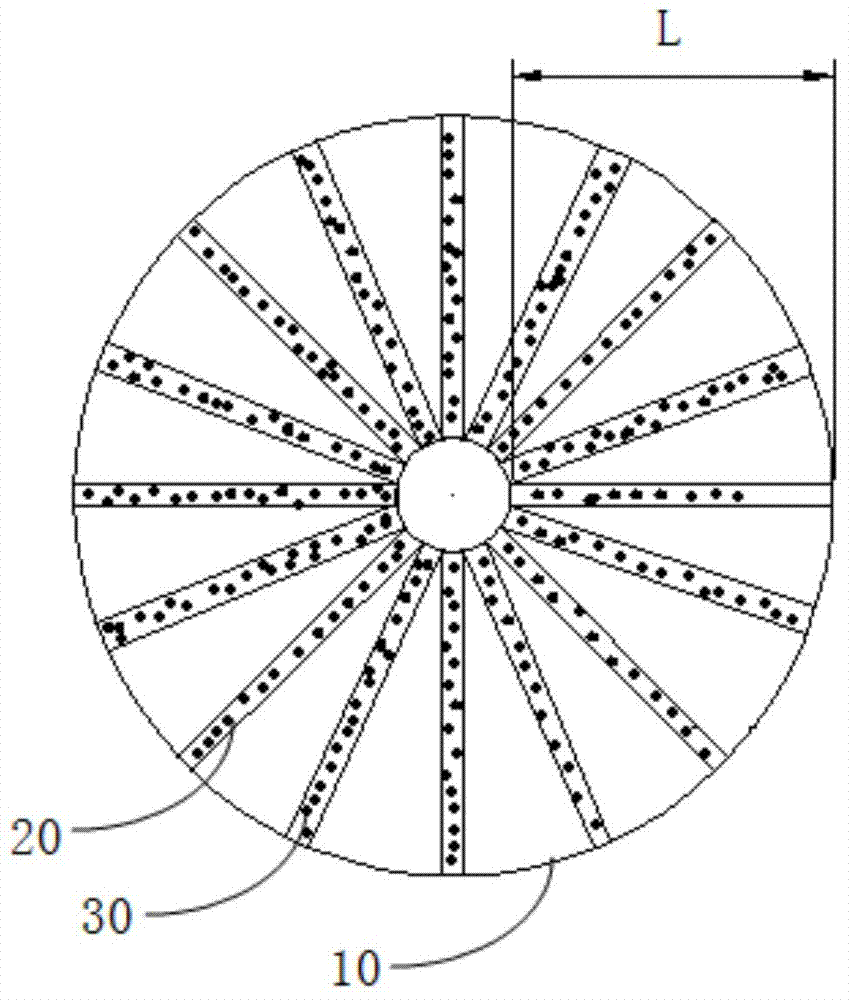

[0033] Then, a pig iron block with a plurality of pore columns is prepared. In this embodiment, such as figure 1 with figure 2 As shown, the pig iron block 10 has a spherical shape with a diameter D of 5 cm. A plurality of hole columns 20 are evenly distributed in the spherical pig iron block 10. The hole diameter d of the hole column 20 is 5 mm, and the length of the hole column 20 is 2.3 cm. The volume of the plurality of hole columns 20 accounts for 40% of the volume of the entire pig iron block 10. In addition, a plurality of hole posts 20 extend from the center of the spherical pig iron block 10 to the surface of the spherical pig iron block 10, and have a radial structu...

Embodiment 2

[0038] The difference from Example 1 is: First, the chemical composition of the deoxidizer prepared in this example is: 80% SiC, 15% Si, 2% SiO 2 , 3% Fe. Next, the diameter D of the spherical pig iron block 10 is 6 cm. The hole diameter d of the hole column 20 is 10 mm, and the length of the hole column 20 is 2.8 cm. The volume of the plurality of hole columns 20 accounts for 45% of the volume of the entire pig iron block 10. The final prepared spherical pig iron block 10 has a density greater than 4g / cm 3 . The deoxidized block prepared in this embodiment is applied to steelmaking and has an effect similar to that in Embodiment 1.

[0039] In summary, compared with the prior art, the deoxidizing block for steelmaking provided by the present invention can make the deoxidizer enter the molten steel for deep deoxidation, with good deoxidation effect, and the final oxygen content in the molten steel can be controlled below 10 ppm. The chemical composition of the deoxidizing bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com