Membrane separation method for resource recovery of sorbic acid in sorbic acid wastewater

A technology of sorbic acid wastewater and sorbic acid, which is applied in the field of separation, can solve the problems of large area occupied by resin equipment, reduced resin life, cumbersome post-treatment, etc., and achieves the effects of low operating costs, improved utilization rate, and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

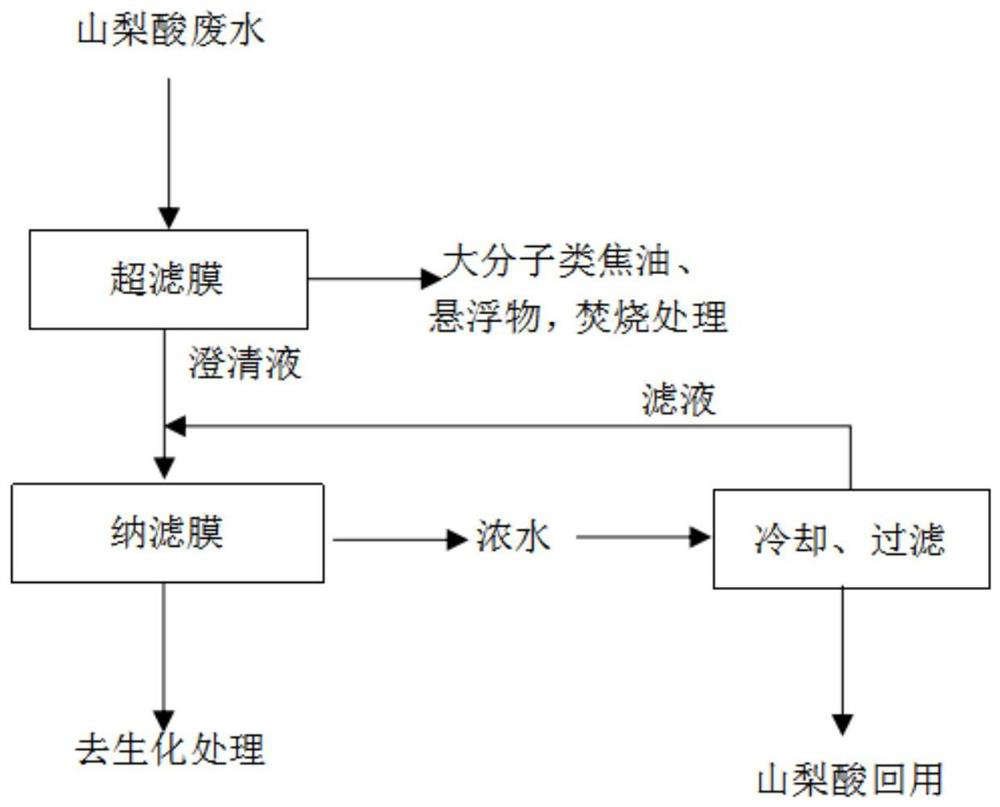

[0054] The wastewater stock solution was first adjusted to pH=2 with liquid alkali, passed through an ultrafiltration membrane device (inorganic membrane retention accuracy 1000Da), controlled pressure 0.1Mpa, temperature 20-30°C, filtered and intercepted solid suspended solids and macromolecular tar substances to obtain Clarify the filtrate; heat the clarified filtrate after ultrafiltration to 90-95°C by heat exchange, and then pass through a nanofiltration membrane concentration device (with an organic membrane interception accuracy of 100Da), control the vacuum degree to -0.1--0.095MPa, and intercept sorbic acid to obtain sorbic acid containing sorbic acid. Acid concentrated water and clear liquid; clear liquid de-biochemical treatment system; concentrated water containing sorbic acid is cooled to 10-15 ° C by cooling water, crystallized, filtered, and sorbic acid is removed from the production system, and the filtrate is incorporated into ultrafiltration. The clear liquid; ...

Embodiment 2

[0056] The wastewater stock solution was first adjusted to pH=3 with liquid alkali, passed through an ultrafiltration membrane device (inorganic membrane retention accuracy 1000Da), controlled pressure 0.25Mpa, temperature 20-30°C, filtered and intercepted solid suspended solids and macromolecular tar substances to obtain Clarify the filtrate; heat the clarified filtrate after ultrafiltration to 80-85°C by heat exchange, and then pass through a nanofiltration membrane concentration device (with an organic membrane interception accuracy of 100Da), control the vacuum degree to -0.095--0.09MPa, and retain sorbic acid to obtain sorbic acid containing sorbic acid. Acid concentrated water and clear liquid; clear liquid to biochemical treatment system; concentrated water containing sorbic acid is cooled to 20-25 ° C by cooling water, crystallized, filtered, and sorbic acid is removed from the production system, and the filtrate is incorporated into ultrafiltration. The clear liquid; s...

Embodiment 3

[0058] The wastewater stock solution was first adjusted to pH=4 with liquid alkali, passed through an ultrafiltration membrane device (with an organic membrane retention accuracy of 2000Da), controlled at a pressure of 0.5Mpa and a temperature of 20-30°C, filtered to intercept solid suspended solids and macromolecular tar substances to obtain Clarify the filtrate; heat the clarified filtrate after ultrafiltration to 70-75°C by heat exchange, and then pass through a nanofiltration membrane concentration device (inorganic membrane retention accuracy 200Da), control the vacuum degree to -0.085--0.08MPa, and retain sorbic acid to obtain sorbic acid containing sorbic acid. Acid concentrated water and clear liquid; clear liquid to biochemical treatment system; concentrated water containing sorbic acid is cooled to 35 ~ 40 ° C by cooling water, crystallized, filtered, and sorbic acid is removed from the production system, and the filtrate is incorporated into ultrafiltration. The clar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com