Solar tracking photovoltaic power generation device

A photovoltaic power generation and sun tracking technology, applied in photovoltaic power generation, photovoltaic modules, solar thermal energy, etc., to achieve the effects of easy maintenance, simple structure, and increased absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

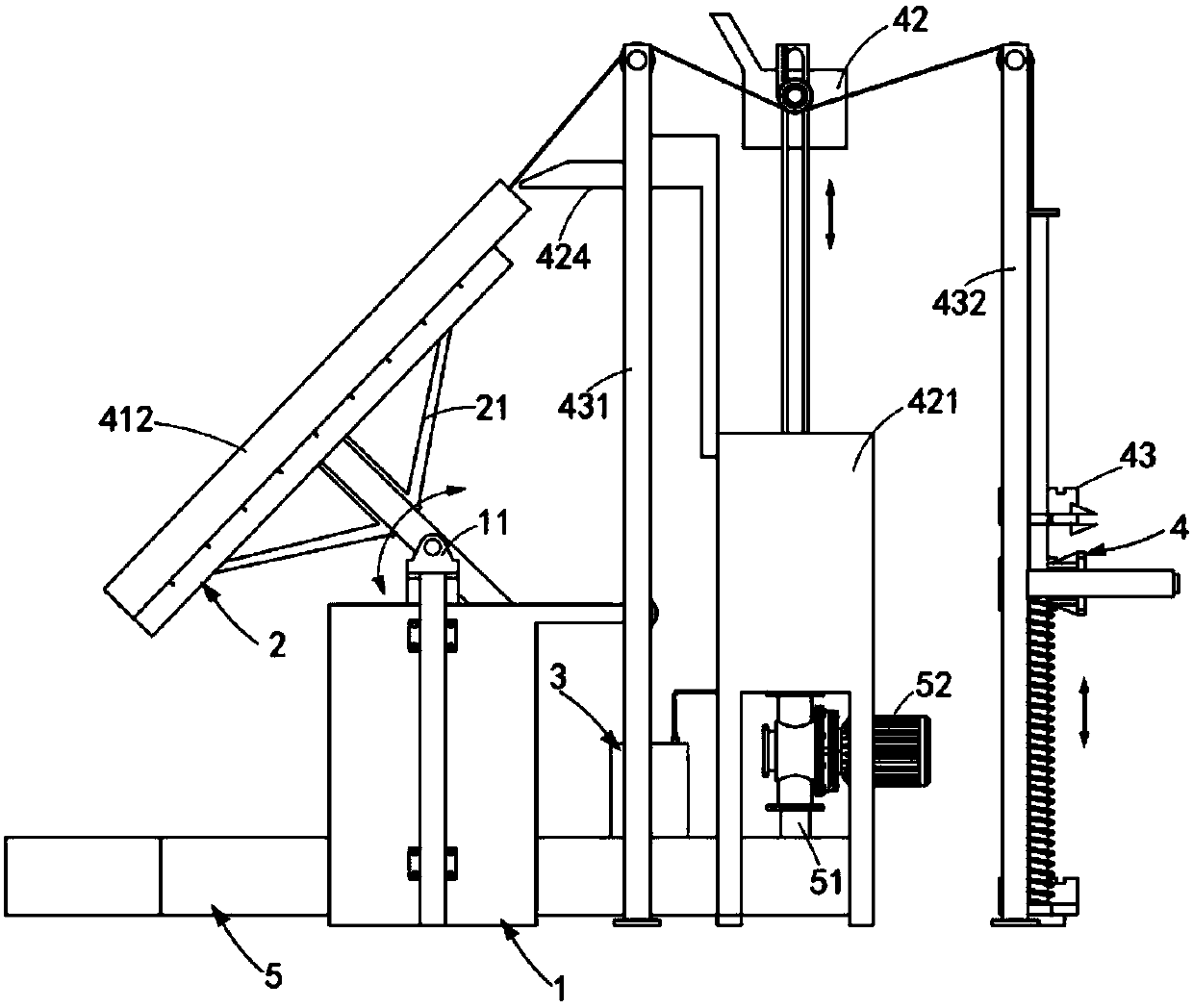

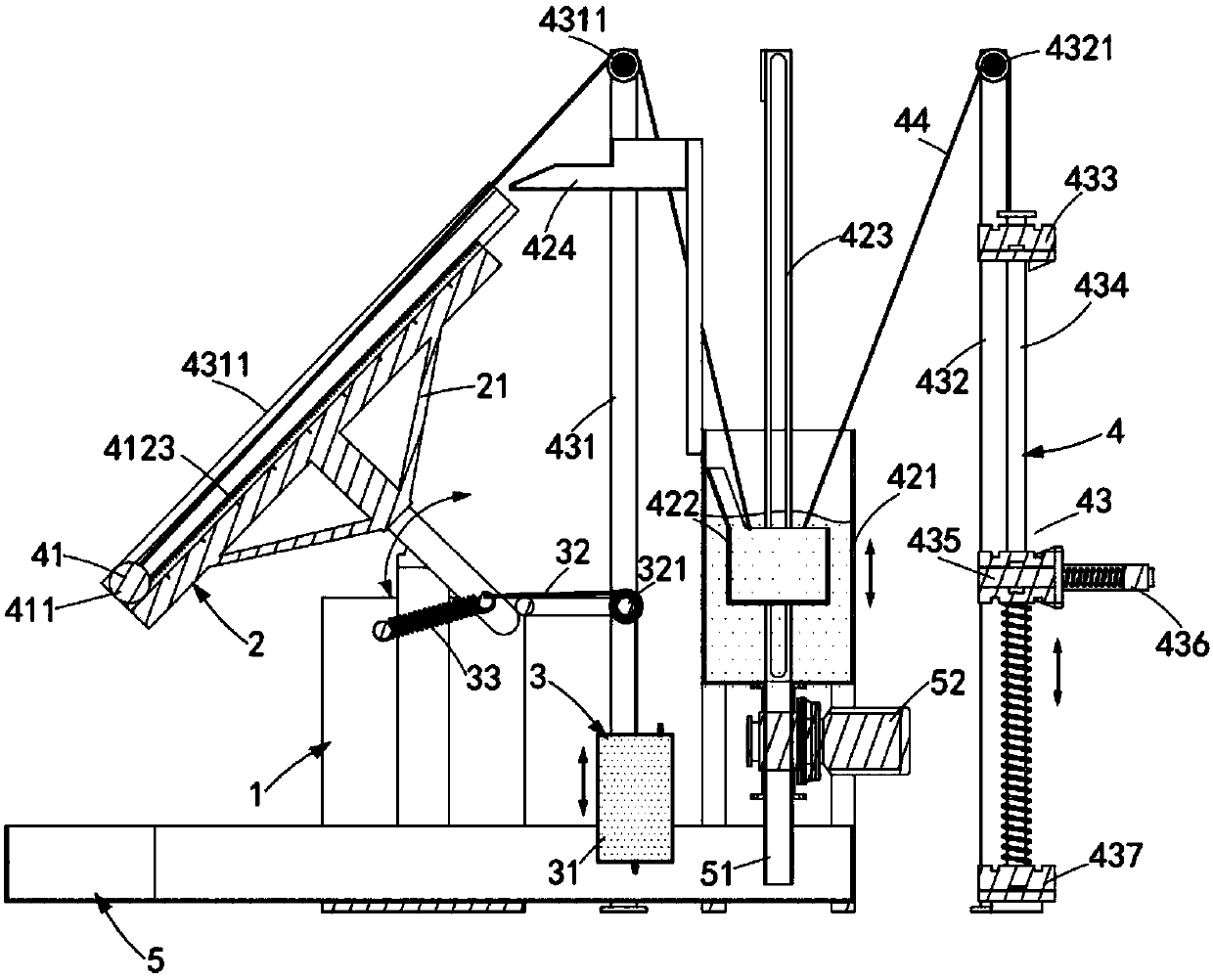

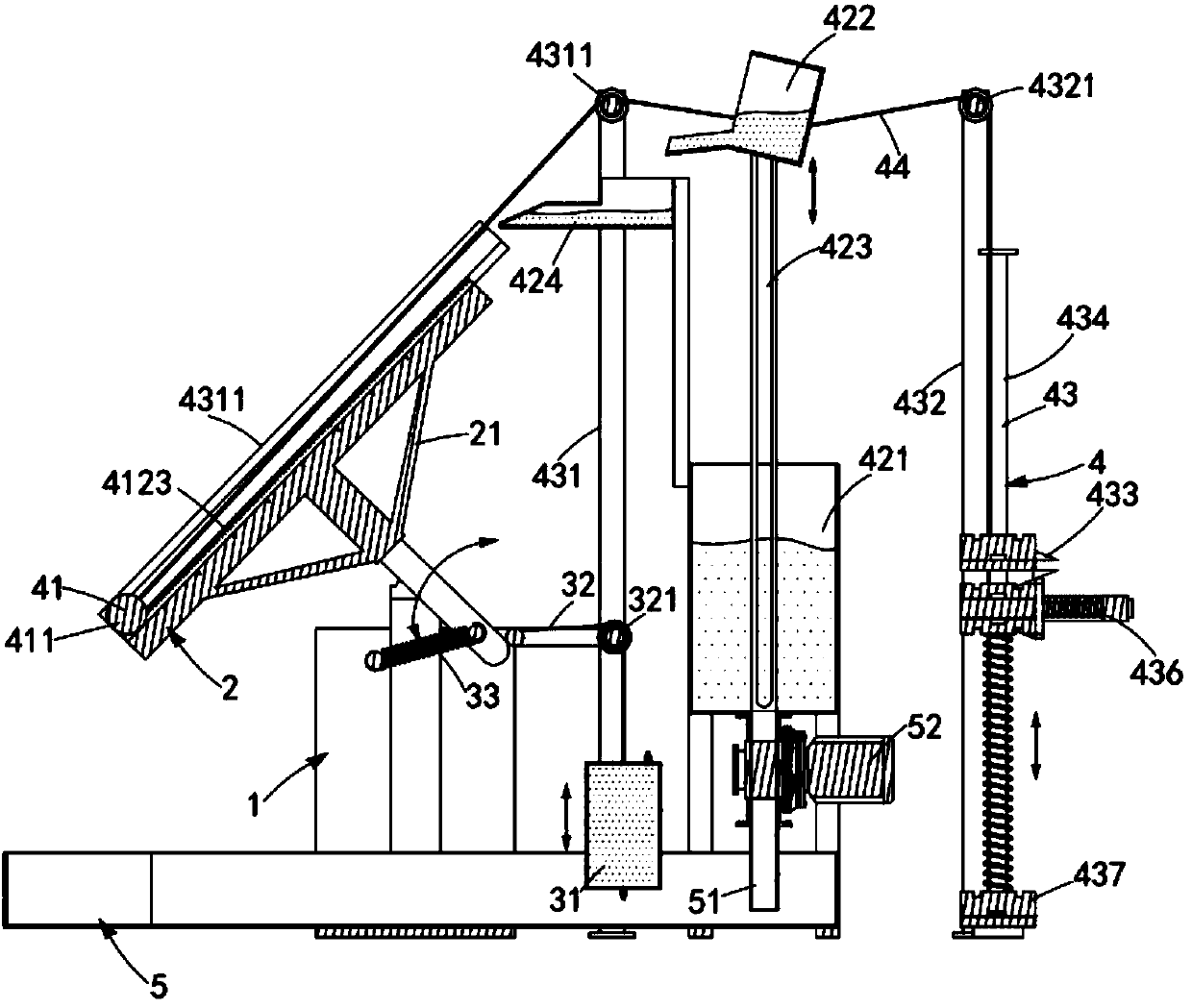

[0064] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a solar tracking photovoltaic power generation device, including:

[0065] Mounting seat 1, the top center of the mounting seat 1 is symmetrically provided with a bearing seat 11;

[0066] A photovoltaic panel 2, the side of the photovoltaic panel 2 facing away from the sun is provided with a bracket 21, and the two ends of the bracket 21 are rotatably arranged on the bearing seat 11;

[0067] Tracking assembly 3, the tracking assembly 3 is arranged below the photovoltaic panel 2, it includes a liquid tank 31, the liquid tank 31 is connected to the end of the bracket 21 through a connecting rope 32, the connecting rope 32 and A first fixed pulley 321 is provided at the place where the mounting seat 1 is wound; and

[0068] The cleaning assembly 4, the cleaning assembly includes a cleaning unit 41, a water adding unit 42 and a driving unit 43, the cleaning unit 41 is arranged on the side facing the sun ...

Embodiment approach

[0095] Such as figure 1 , figure 2 , Figure 10 and Figure 11 As shown, as a preferred implementation manner, the drive unit 43 includes:

[0096] The first pulley frame 431, the first pulley frame 431 is arranged between the photovoltaic panel 2 and the water tank 421, the second connecting rope 44 is wound on it, and it is connected with the second connecting rope 44 A second fixed pulley 4311 is provided at the winding part;

[0097] The second pulley frame 432, the second pulley frame 432 is arranged on the rear side of the water tank 421, the second connecting rope 44 is wound on it, and it is arranged with the winding position of the second connecting rope 44 There is a third fixed pulley 4321;

[0098] The first counterweight 433, the first counterweight 433 is connected with the second connecting rope 44, it is suspended directly below the second pulley frame 432, and it slides along the symmetrically arranged optical axis 434 ;

[0099] An electromagnet 435, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com