Electrode assembly and plasma source for generating a non-thermal plasma, and method for operating a plasma source

A non-thermal plasma, plasma source technology, applied in the direction of plasma, ion source/gun, particle separator tube parts, etc., can solve the problems that hinder the miniaturization of equipment, take a lot of time, hard, etc., and achieve uniform distribution, the effect of uniform output distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

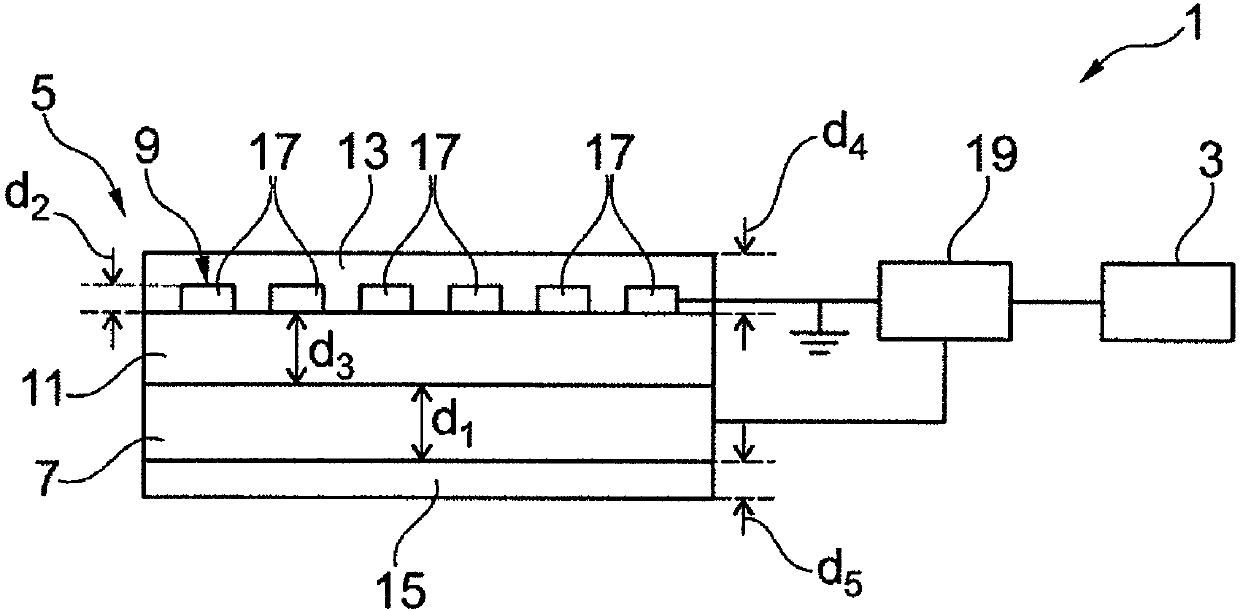

[0080] figure 1 A schematic diagram of an exemplary embodiment of a plasma source 1 arranged to generate a non-thermal plasma is shown. The plasma source 1 has a voltage source 3 electrically connected to an electrode arrangement 5 . As such, the electrode arrangement 5 is arranged to generate an athermal plasma.

[0081] It has a first electrode 7 and a second electrode 9 , between which a dielectric element 11 is arranged such that the two electrodes 7 , 9 are electrically insulated from and spaced apart from each other by the dielectric element 11 . The two electrodes 7 , 9 and the dielectric element 11 form a stack, wherein the dielectric element is arranged on the first electrode 7 and the second electrode 9 is arranged on the dielectric element 11 as seen in the stack direction.

[0082] Viewed in the stacking direction, the first electrode 7 has a first thickness d of at least 10 μm 1 , wherein the second electrode 9 also has a second thickness d of at least 1 μm to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com