A kind of flow guiding nonwoven composite material and preparation method thereof

A composite material and non-woven technology, applied in bandages, absorbent pads, clothing, etc., can solve the problems of blocking liquid diffusion channels, heavy weight, and increasing the cost of absorbent sanitary products, and achieve the effect of thin thickness and small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

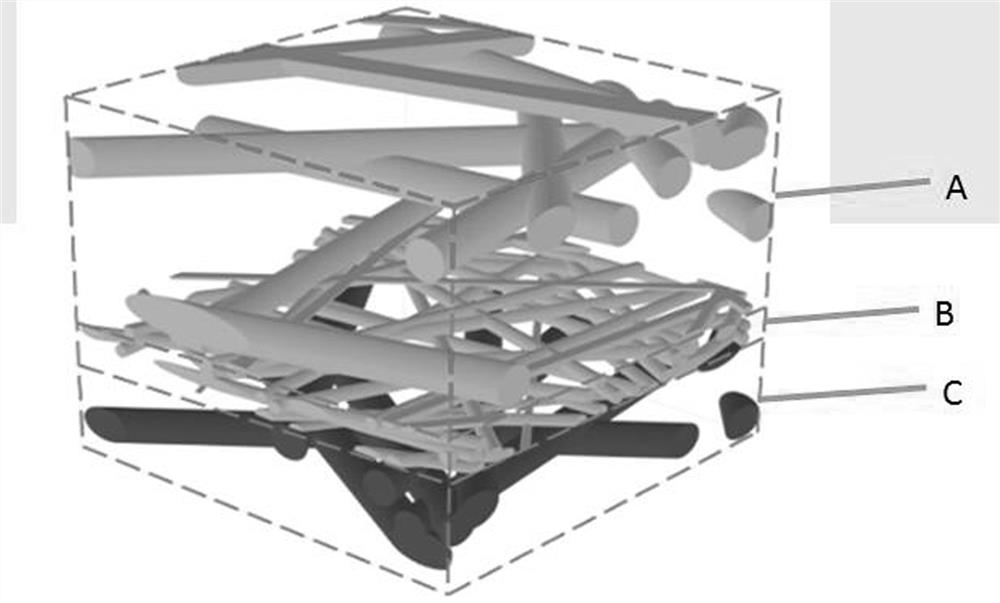

[0030] The absorbent core of this example uses a flow-conducting nonwoven composite material such as figure 1 As shown, from top to bottom are laminated composite consolidated air-through non-woven fabrics, polypropylene melt-blown non-woven fabrics and polypropylene spun-bonded non-woven fabrics. Its preparation method is as follows:

[0031] (1) According to the polypropylene spunbond process, the grammage is 8g / m 2 Polypropylene spunbond nonwoven fabrics, in the polypropylene spunbond process, polypropylene chips and hydrophilic masterbatches are added in a mass ratio of 19:1;

[0032] (2) Polypropylene melt-blown nonwovens are prepared by the melt-blown method. When the melt-blown non-woven fabric is spun, water-soluble polyester chips, hydrophilic masterbatches, and polypropylene chips are used in a mass ratio of 2:1:17 Add, and then produce and process according to the technology of melt-blown nonwovens; in the preparation process, 13g / m 2 The hot-air non-woven fabric...

Embodiment 2

[0037] The flow-guiding non-woven composite material for the absorbent core in this embodiment is composed of sequentially laminated and consolidated air-through non-woven fabric, polypropylene melt-blown non-woven fabric and polypropylene spun-bonded non-woven fabric. Its preparation method is as follows:

[0038] (1) First, according to the polypropylene spunbond process, the grammage is 12g / m 2 Polypropylene spunbond nonwoven fabrics, in the polypropylene spunbond process, the polypropylene slices and hydrophilic masterbatches are added in a mass ratio of 18:1;

[0039] (2) Polypropylene melt-blown nonwovens are prepared by the melt-blown method. When the melt-blown non-woven fabric is spun, water-soluble polyester chips, hydrophilic masterbatches, and polypropylene chips are prepared in a mass ratio of 3:1:16 Add, and then carry out production and processing according to the technology of melt-blown nonwoven fabric; In the preparation process, polypropylene spunbonded non...

Embodiment 3

[0044] The flow-guiding non-woven composite material for the absorbent core in this embodiment is composed of sequentially laminated and consolidated air-through non-woven fabric, polypropylene melt-blown non-woven fabric and polypropylene spun-bonded non-woven fabric. Its preparation method is as follows:

[0045] (1) According to the polypropylene spunbond process, the grammage is 9g / m 2 Polypropylene spunbond nonwoven fabrics, in the process of polypropylene spunbond, polypropylene slices and hydrophilic masterbatches are added according to the mass ratio of 20:1;

[0046] (2) Polypropylene melt-blown nonwovens are prepared by the melt-blown method. When the melt-blown non-woven fabric is spun, water-soluble polyester chips, hydrophilic masterbatches, and polypropylene chips are used in a mass ratio of 2:1:18. Add, and then produce and process according to the technology of melt-blown nonwovens; in the preparation process, 15g / m 2 The hot air non-woven fabric is laid unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com