Orally disintegrating clozapine tablets prepared by 3D printing and preparation method thereof

An orally disintegrating tablet and 3D printing technology are applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas. Convenience and quickness, the effect of improving the success rate and compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

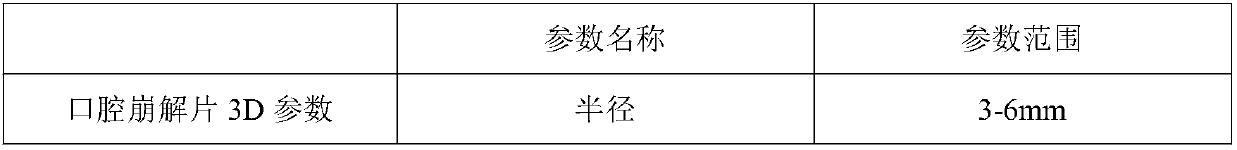

[0029] The prescription of 3D printed clozapine orally disintegrating tablets is as follows:

[0030]

[0031] 3D printing parameters are as follows:

[0032]

[0033] The preparation method is as follows:

[0034] (1) According to the pre-set parameters, use CAD and other software to model, and convert it into a st1 format file and import it into the LTY software control system of the 3D printer.

[0035] (2) Calculated by weight percentage, 20% clozapine, 65% mannitol, 10% sucrose, and 305% PVP K are mixed evenly in proportion, and packed into the powder and ink cartridge of the 3D printing rapid prototyping machine as medicinal powder.

[0036] (3) Put 25% ethanol into the cartridge.

[0037] (4) The control system outputs printing instructions, the powder spreading device spreads the powder on the 3D printing platform, the printing nozzle of the 3D printing system moves in the X-Y axis direction, and sprays the bonding liquid on the powder according to the set mode...

Embodiment 2

[0042] The prescription of 3D printed clozapine orally disintegrating tablets is as follows:

[0043]

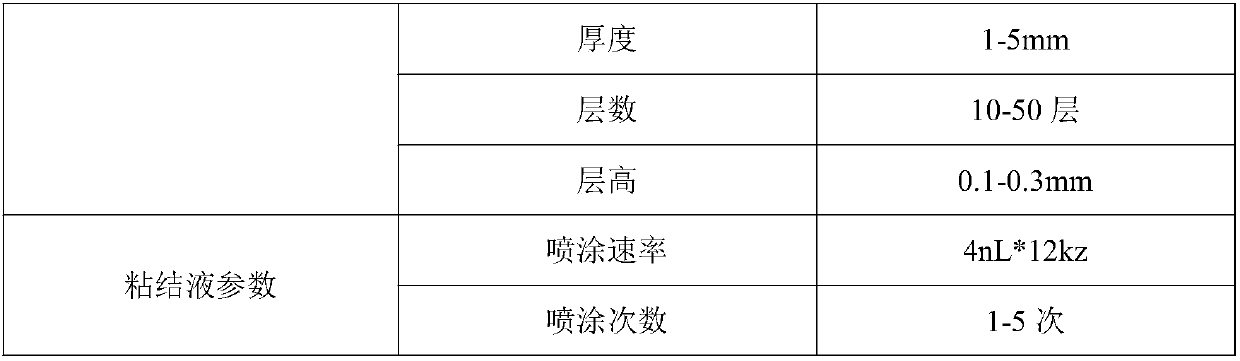

[0044] 3D printing parameters are as follows:

[0045]

[0046]

[0047] The preparation method is as follows:

[0048] (1) According to the pre-set parameters, use CAD and other software to model, and convert it into a st1 format file and import it into the LTY software control system of the 3D printer.

[0049] (2) Calculated by weight percentage, mix clozapine 30%, pregelatinized starch 50%, maltodextrin 10%, PVPK 308%, and sucralose 2% in proportion, and load it into a 3D printing rapid prototyping machine as a medicine powder in the toner cartridge.

[0050] (3) Put 2% PVP K30-25% ethanol into the cartridge.

[0051] (4) The control system outputs printing instructions, the powder spreading device spreads the powder on the 3D printing platform, the printing nozzle of the 3D printing system moves in the X-Y axis direction, and sprays the bonding liquid on the...

Embodiment 3

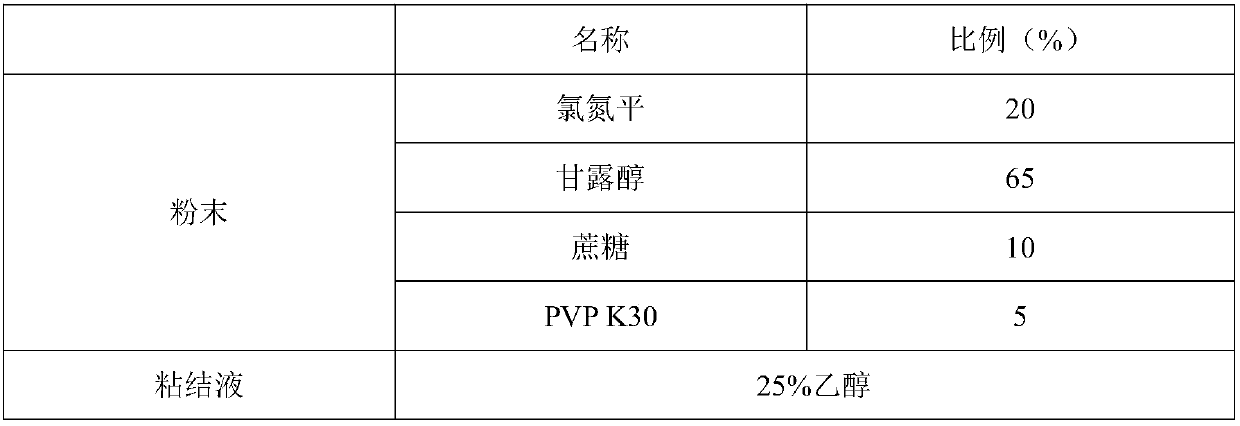

[0056] The prescription of 3D printed clozapine orally disintegrating tablets is as follows:

[0057]

[0058] The 3D printing parameters of this embodiment are as follows:

[0059]

[0060]

[0061] The preparation method is as follows:

[0062] (1) According to the pre-set parameters, use CAD and other software to model, and convert it into a st1 format file and import it into the LTY software control system of the 3D printer.

[0063] (2) Calculated by weight percentage, mix 50% of clozapine, 38% of mannitol, 10% of PVP K30, and 2% of stevioside evenly in proportion, and put them into the powder and ink box of the 3D printing rapid prototyping machine as medicine powder.

[0064] (3) Fill the cartridge with 50% ethanol.

[0065] (4) The control system outputs printing instructions, the powder spreading device spreads the powder on the 3D printing platform, the printing nozzle of the 3D printing system moves in the X-Y axis direction, and sprays the bonding liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Storey height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com