Drug-loaded polyvinyl alcohol microsphere

A technology of polyvinyl alcohol microspheres and drug loading, applied in the field of drugs, can solve the problems of slow drug release rate and small maximum drug absorption, and achieve the effects of fast drug release rate, excellent effect and uniform particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

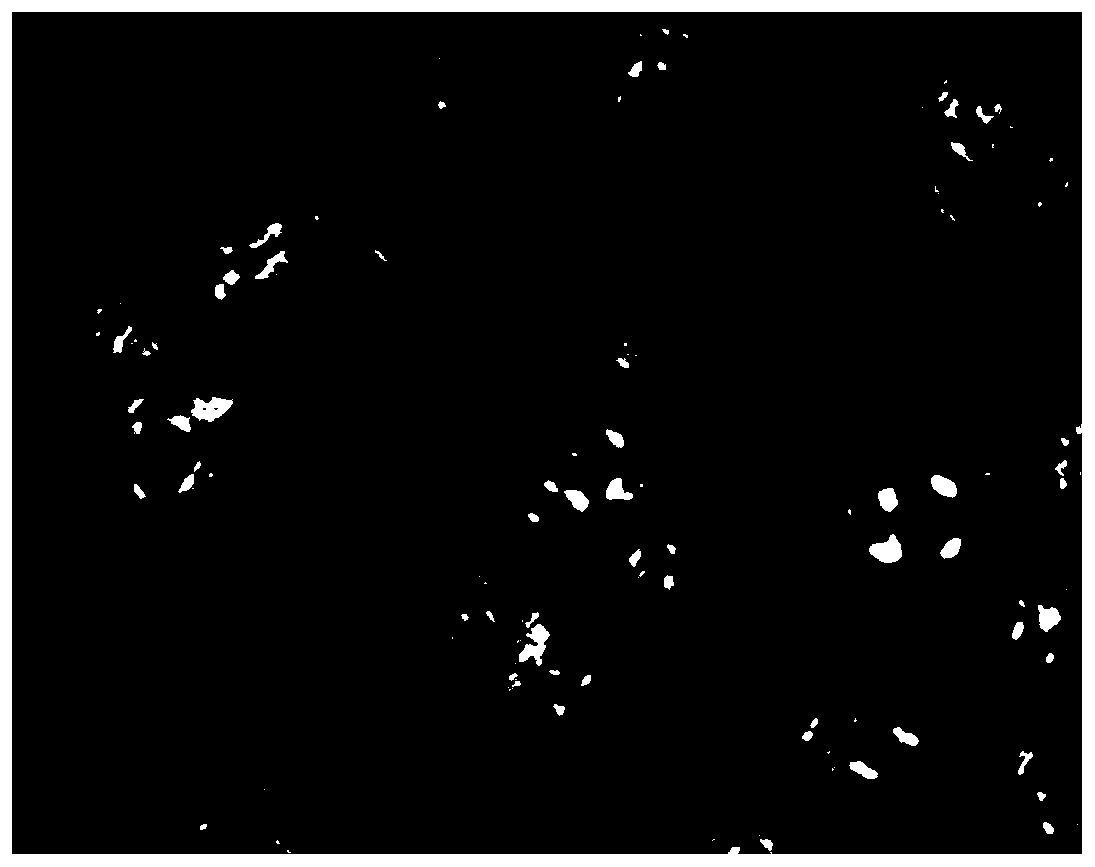

Embodiment 1

[0039] Dissolve aminoacetaldehyde dimethyl acetal in dichloromethane in a pear-shaped flask; stir, slowly add acryloyl chloride to the liquid phase at 0°C, the reaction is exothermic; slowly add triethylamine dropwise, and let the system Rise to room temperature and react for another 3 hours; after the reaction is completed, wash with water and dichloromethane, suspend to dry and suction filter, and seal and store at room temperature.

[0040] Accurately weigh a certain amount of polyvinyl alcohol particles, swell in deionized water for a period of time, place them in a water bath and heat up to 90°C with the water bath, stir to dissolve them completely, and obtain transparent polyethylene with a certain viscosity Alcohol solution, the mass fraction is 10%. Under the action of magnetic stirring, add N-acryloyl-aminoacetaldehyde-dimethyl acetal into the polyvinyl alcohol solution, then adjust the pH value of the system to 1-2 with hydrochloric acid, and react at 40°C for 24 hou...

Embodiment 2

[0043] The cross-linking reaction temperature of the polyvinyl alcohol solution in Example 1 was replaced from 55°C to 25°C, and the other reaction conditions were the same as in Example 1, and the microsphere product M2 was obtained by using this method. The test results showed that the dispersion of microspheres M2 prepared at 25°C was poor, and the adhesion between microspheres was very serious.

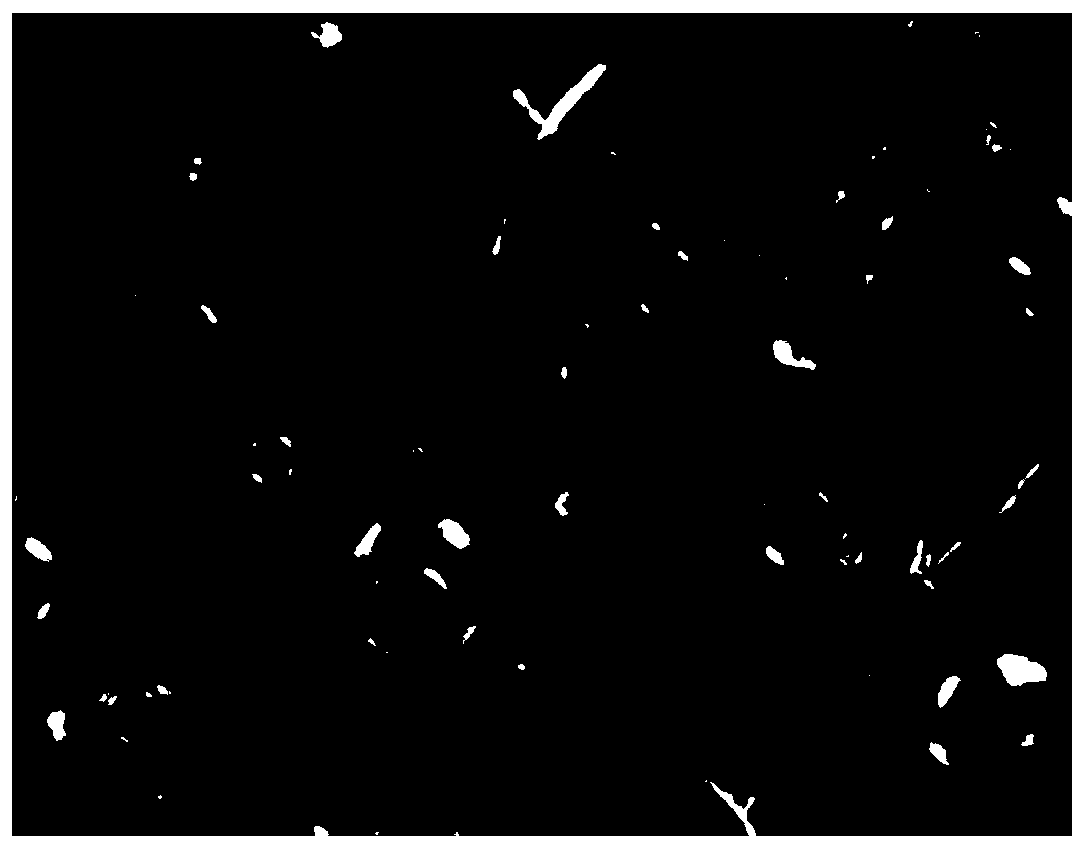

Embodiment 3

[0045] The cross-linking reaction temperature of the polyvinyl alcohol solution in Example 1 was replaced from 55°C to 80°C, and the other reaction conditions were the same as in Example 1, and the microsphere product M3 was obtained by using this method. The test results show that the microspheres M3 prepared at 80°C have good dispersion, but the spherical shape is irregular, the particle size is large and the distribution is not uniform.

[0046] From the comparison of Examples 1-3, it can be seen that the crosslinking reaction temperature has a significant impact on the morphology, dispersibility and particle size distribution of the microspheres. The present invention proves through the above tests that only by controlling the crosslinking reaction temperature around 55°C can the polyvinyl alcohol microspheres with better shape, higher dispersibility and uniform particle size distribution be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com