Stirring device

A stirring device and mixing barrel technology, which is applied in the direction of mixer accessories, transportation, packaging, dissolution, etc., can solve the problems of insufficient mixing of raw materials on both sides of the mixing barrel, prone to transmission failures, etc., and achieve the effect of convenient operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

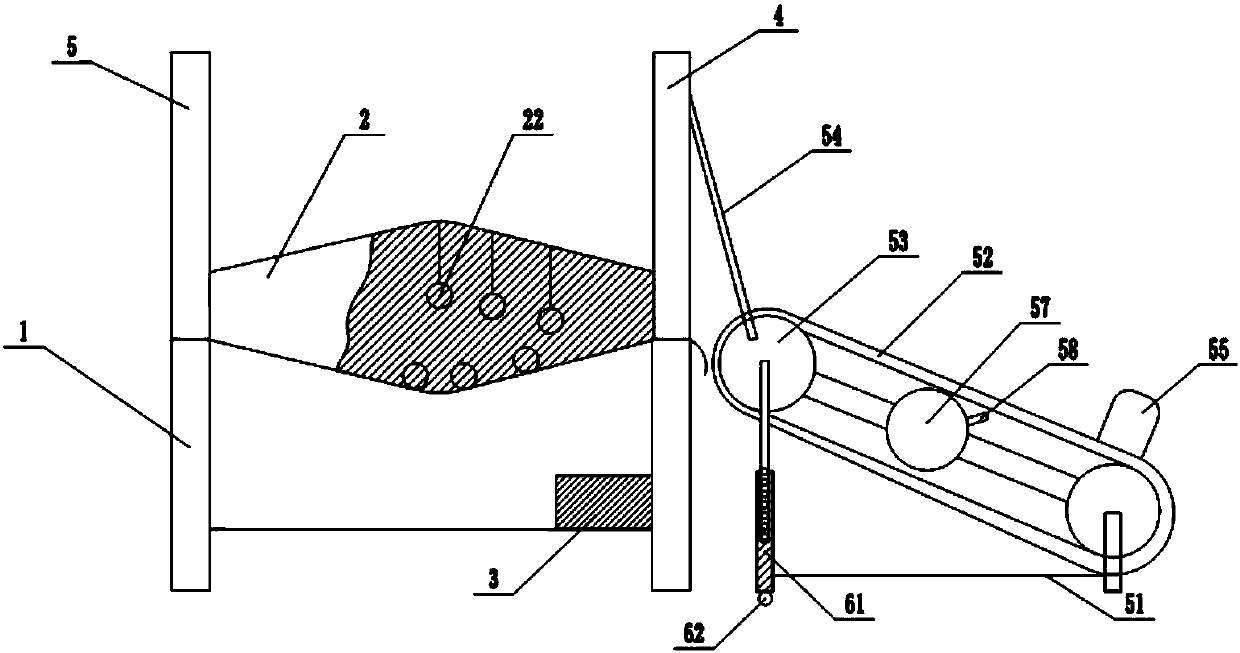

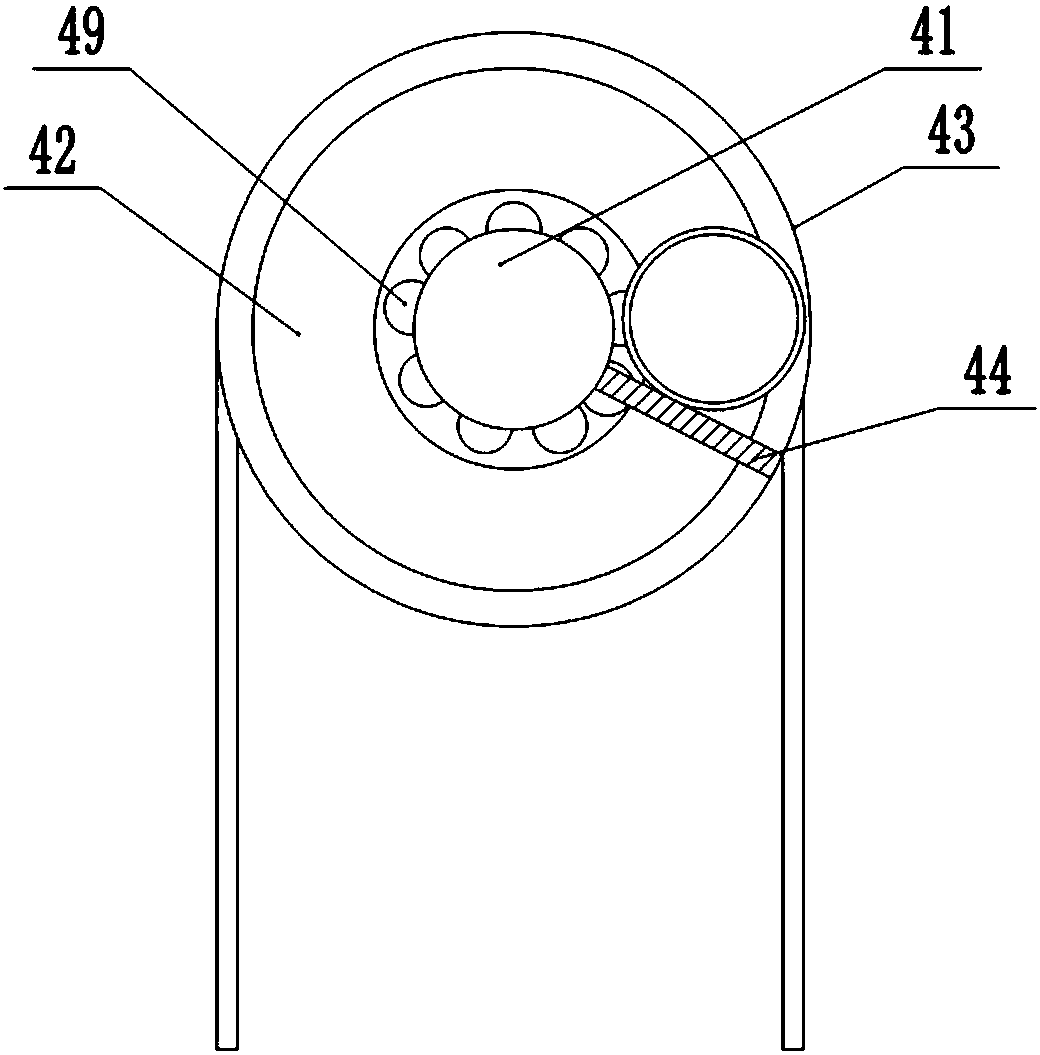

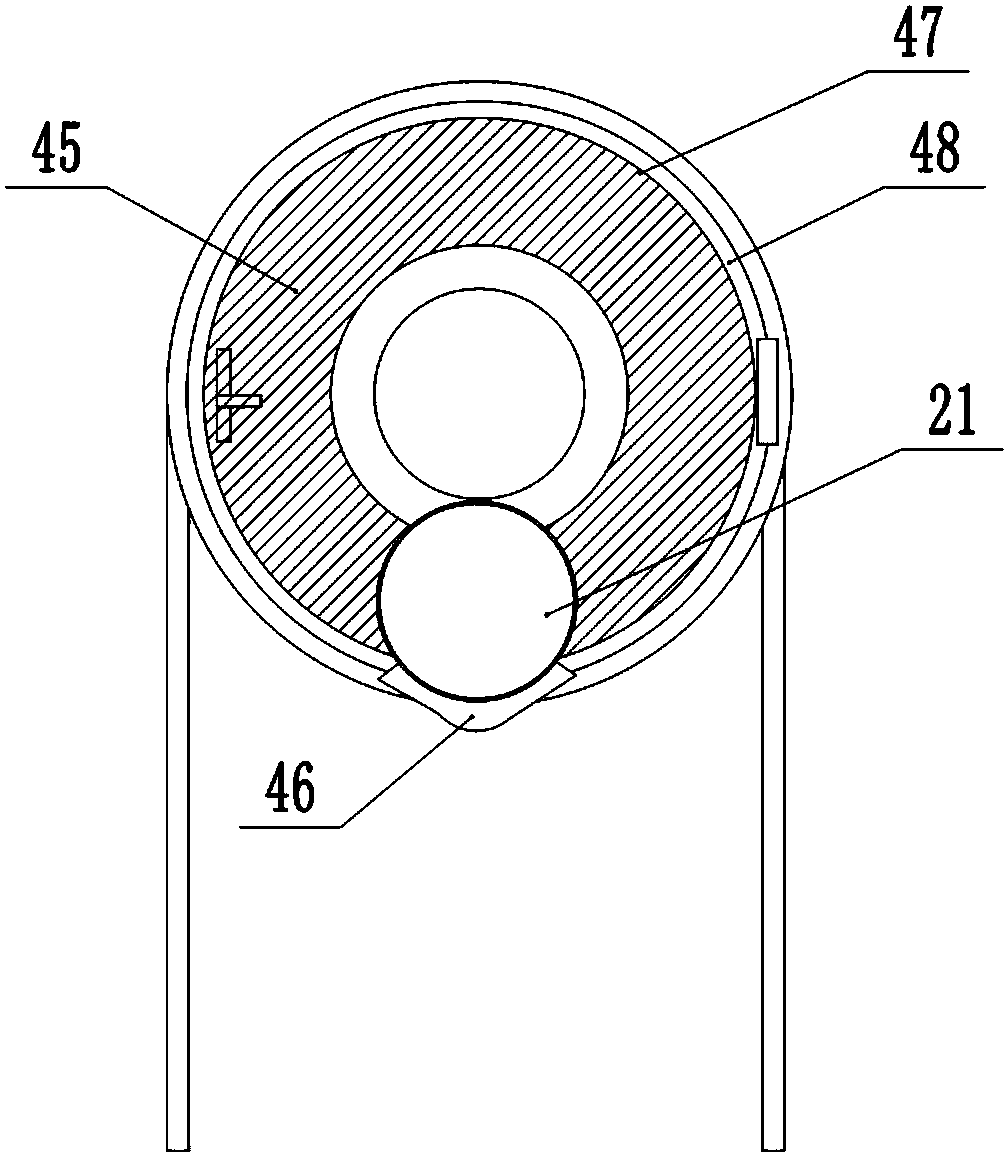

[0021] The reference signs in the drawings of the description include: frame 1, mixing tank 2, electrical control box 3, front drive mechanism 4, rear drive mechanism 5, feed port 21, pendulum 22, rotating shaft 41, groove 42, circle Disk 43, baffle plate 44, strip hole 45, curved part 46, warehouse door 47, sealing ring 48, protrusion 49, support frame 51, conveyor belt 52, transmission wheel 53, connecting rod 54, telescopic block 55, backguy 56, Support wheel 57, telescopic rod 58, adjustment rod 61, pulley 62.

[0022] as attached Figure 1-3 Shown: a mixing device, including a frame 1, a feeding mechanism, a mixing bucket 2, an electrical control box 3 and a driving mechanism, the feeding mechanism includes a support frame 51, a conveyor belt 52 and a transmission wheel 53, and the mixing bucket 2 is horizontal The mixing tank has a bulge in the middle, and is shuttle-shaped as a whole. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com