Intelligent cleaning robot for photovoltaic power station

A technology for cleaning robots and photovoltaic power plants, applied in photovoltaic power plants, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of poor photovoltaic panel capacity, use of labor, and poor photovoltaic power station conditions, so as to achieve stable walking and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

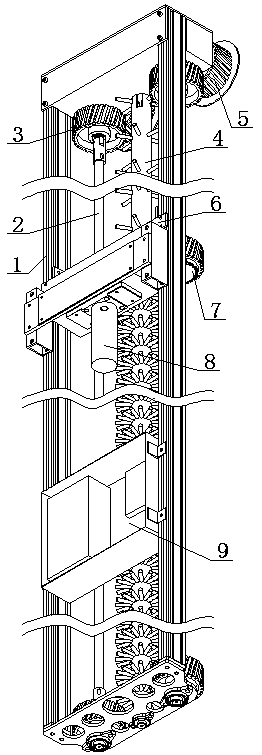

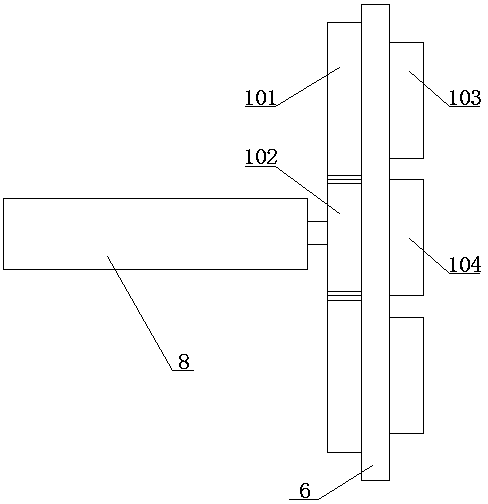

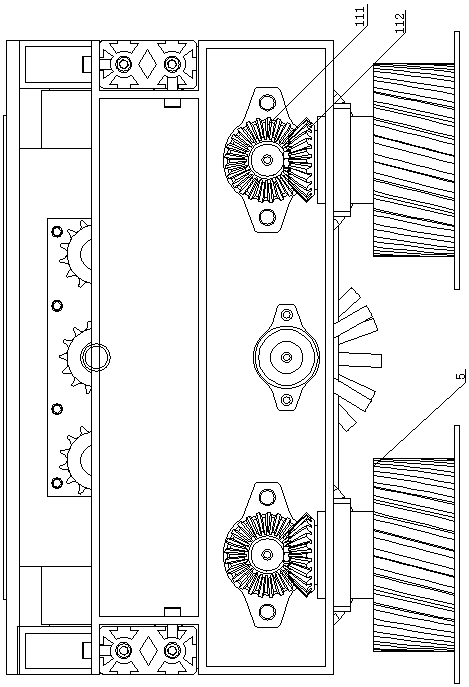

[0041] as attached figure 1 , attached figure 2 And attached image 3 As shown, a photovoltaic power plant intelligent cleaning robot of the present invention includes a frame 1 and a brush roller 4 assembled on the frame 1, a transmission shaft 2, a guide mechanism, a limit sensor and a driving device, and the frame 1 is a cuboid frame, the axial length of the brush roller 4 is consistent with the length of the inclined direction of the photovoltaic panel 14, the brush roller 4 is rotatably assembled in the middle end of the frame 1, and the drive shaft 2 is rotatably assembled in the machine On the frame 1, the transmission shaft 2 and the brush roller 4 are arranged side by side at intervals, and the two ends of the brush roller 4 are equipped with rotatable walking wheels 3, and the walking wheels 3 can walk along the top surface of the photovoltaic panel 14; the guide mechanism includes relative The guide wheels 5 located on both sides of the axial direction of the bru...

Embodiment 2

[0053] as attached Figure 4As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: the width side frame at the top of the photovoltaic panel array 15 is the top frame guide rail 141 of the photovoltaic panel array, located at The width frame at the bottom of the photovoltaic panel square array 15 is the bottom frame guide rail 142 of the photovoltaic panel square array, between the top frame guide rails 141 of every two adjacent photovoltaic panel square arrays and between each adjacent two photovoltaic panel square arrays Transition guide rails are laid between the bottom frame guide rails 142 of the photovoltaic panel array. The top frame guide rail 141 of the photovoltaic panel square array and the corresponding top transition guide rail 12 cooperate to form the top walking track. The corresponding bottom transition guide rail 13 cooperates to form the bottom walking track, and the above-m...

Embodiment 3

[0056] as attached Figure 5 And attached Figure 6 As shown, this embodiment is a further improvement on the basis of Embodiment 2. The difference between this embodiment and Embodiment 2 is that a parking mechanism is provided outside the photovoltaic panel array, and the parking mechanism includes a parking panel and a The parking position sensor and the brush lever on the top, the brush lever is set above the parking panel through the L-shaped arm lever, and the brush lever is set above the parking panel through the arm lever, which is used to control the photovoltaic panel power generation unit moved below it The photovoltaic panel 14 in it is cleaned; there are two parking mechanisms, and the two parking mechanisms are relatively arranged at the head end and the tail end of the preset stroke. The preset stroke is that the cleaning robot walks along the length direction of the photovoltaic panel array.

[0057] Among them, the two parking mechanisms are the head parking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com