Environment-friendly cement foaming material processing device and method

A technology for cement foaming and material processing, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc. The effect of structural order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

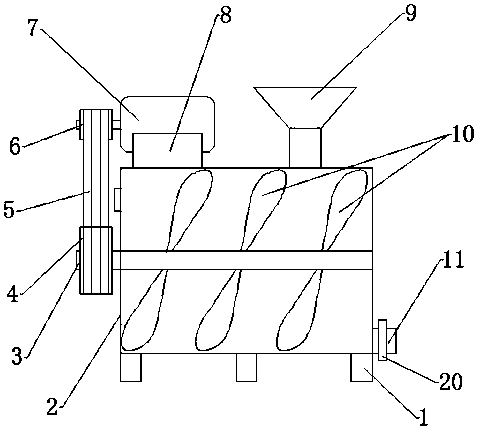

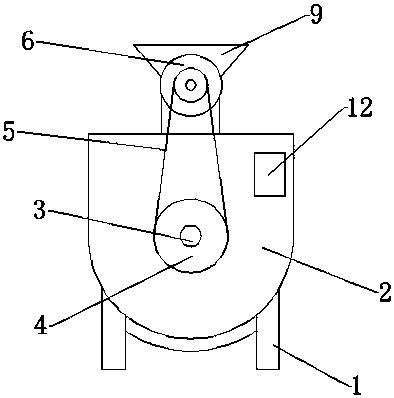

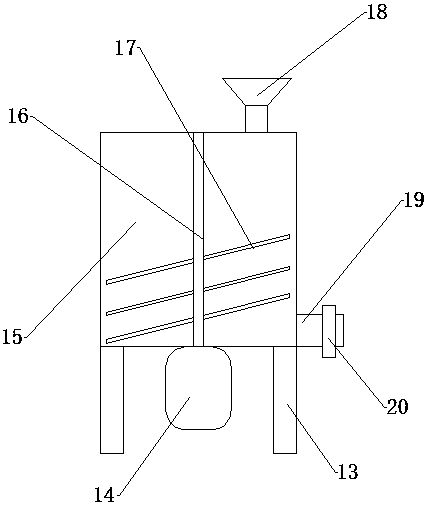

[0026] Such as figure 1 , figure 2 and image 3 Shown, a kind of environment-friendly cement foaming material processing device and processing method, comprise foaming agent stirring chamber 2, mixing chamber 15 and controller 12, below foaming agent stirring chamber 2 are provided with stirring support 1, discharge pipe 11 and A valve 20, a stirring spindle 3 and a stirring blade 10 are arranged in the middle of the foaming agent stirring chamber 2, and the stirring spindle 3 drives the stirring blade 10 to rotate at a high speed, and exposes the stirring blade 10 to the air, thereby driving the air to mix with the foaming liquid to form a Foaming agent, a motor support 8, a stirring motor 7 and a foaming liquid feed hopper 9 are arranged above the foaming agent stirring chamber 2, and a controller 12, a stirring pulley 4, and a motor belt are arranged on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com