System and process for producing artificial stones or fireproof thermal-insulation materials by utilizing rotary kiln system

An artificial stone, fireproof and thermal insulation technology, applied in the cutting of textile materials, non-woven fabrics, textiles and papermaking, etc., can solve the problems of large temperature rise and small production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

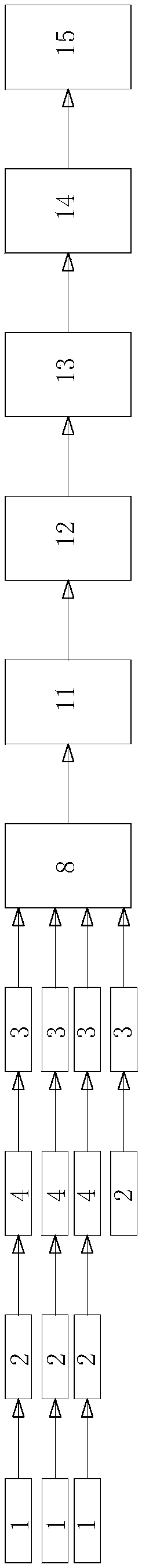

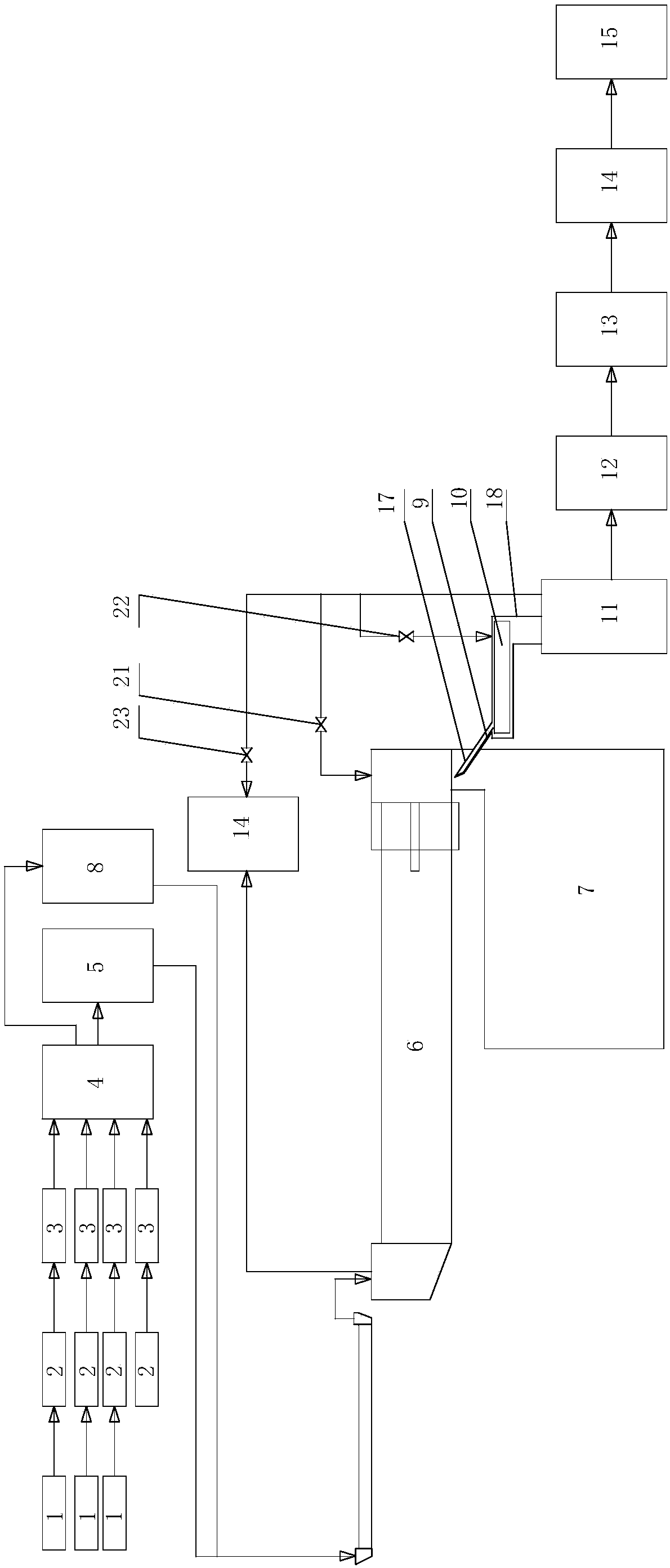

[0071] A system for producing artificial stone using a rotary kiln system, which includes a crusher 1, a raw material storehouse 2, a batching weighing scale 3, a pulverizer 4, a homogenizing storehouse 5, a rotary kiln 6, a grate cooler 7 and Artificial stone feeding warehouse 8, artificial stone chute 9, plate feeder 10, melting furnace 11, forming machine 12, crystallization kiln 13, polishing machine 14, artificial stone cutting machine 15 and controller 16; artificial stone chute 9 A heat preservation shell 17 is provided, a heat preservation cover 18 is provided on the apron feeder 10, a first temperature sensor 19 is provided in the rotary kiln 6, a second temperature sensor 20 is provided in the heat preservation cover 18,

[0072] The discharge port of the pulverizer 4 is respectively connected with the feed port of the homogenization storehouse 5 and the feed port of the artificial stone feed storehouse 8, and the discharge port of the artificial stone feed storehouse...

Embodiment 2

[0086] The traditional artificial stone production system includes crusher 1, raw material warehouse 2, pulverizer 4, batching scale 3, artificial stone feeding warehouse 8, melting furnace 11, molding machine 12, crystallization kiln 13, polishing machine 14 and artificial stone cutting machine 15.

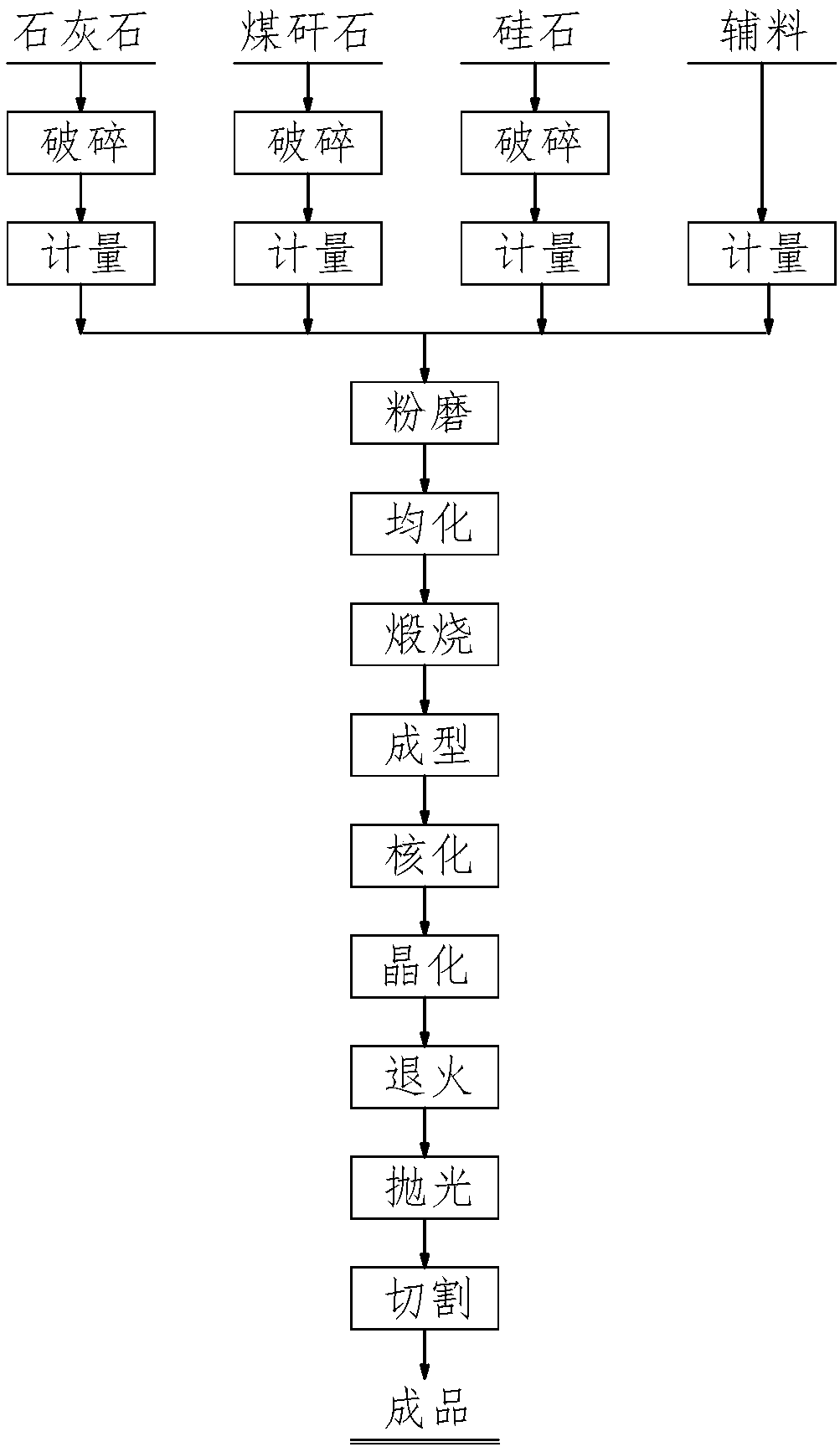

[0087] Utilize the system described in embodiment 2 to produce CaO-Al 2 o 3 -SiO 2 When it is a microcrystalline stone,

[0088] Firstly, after limestone, coal gangue and silica are crushed by crusher 1, buffered by raw material warehouse 2, weighed by ingredient weighing scale 3, and ground by grinding machine 4, they are transported together with the measured auxiliary materials to artificial stone feeding warehouse 8 for standby ; Wherein the proportion of each component in the batch is 25wt% of limestone, 21wt% of coal gangue, 47wt% of silica, and 7wt% of auxiliary materials;

[0089] Secondly, the batch materials in the artificial stone feeding warehouse 8 are transporte...

Embodiment 3

[0092] Utilize the system of embodiment 1 the present invention to produce artificial stone and the system of embodiment 2 traditional production of artificial stone to produce microcrystalline stone, its direct material cost and energy consumption are listed in the following table

[0093] Unit: ton

[0094]

[0095]

[0096] As can be seen from the above table, the cost of producing microcrystalline stone in Example 1 is 53.71 yuan / square meter, compared with the cost of producing microcrystalline stone in Example 2 87.58 yuan / square meter, reducing the direct material cost of 33.87 yuan / square meter, A reduction of 38.67%. Among them, the direct material cost of molten materials is 341.41 yuan / ton (70.7+53.35+3.96+213.4=341.41), which is 768.6 yuan / ton lower than the direct material cost of traditional melting kiln 1110 yuan / ton, which is 69.24% lower.

[0097] It can be seen that the present invention makes full use of the low-cost characteristics of the rotary kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com