A double-hole double-fluid grouting method

A double-liquid grouting and grouting technology, which is applied in construction, infrastructure engineering, soil protection, etc., can solve the problems of short mixing time, affecting strength, and lack of strength, so as to increase the expansion area, improve the degree of fastening, and improve The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

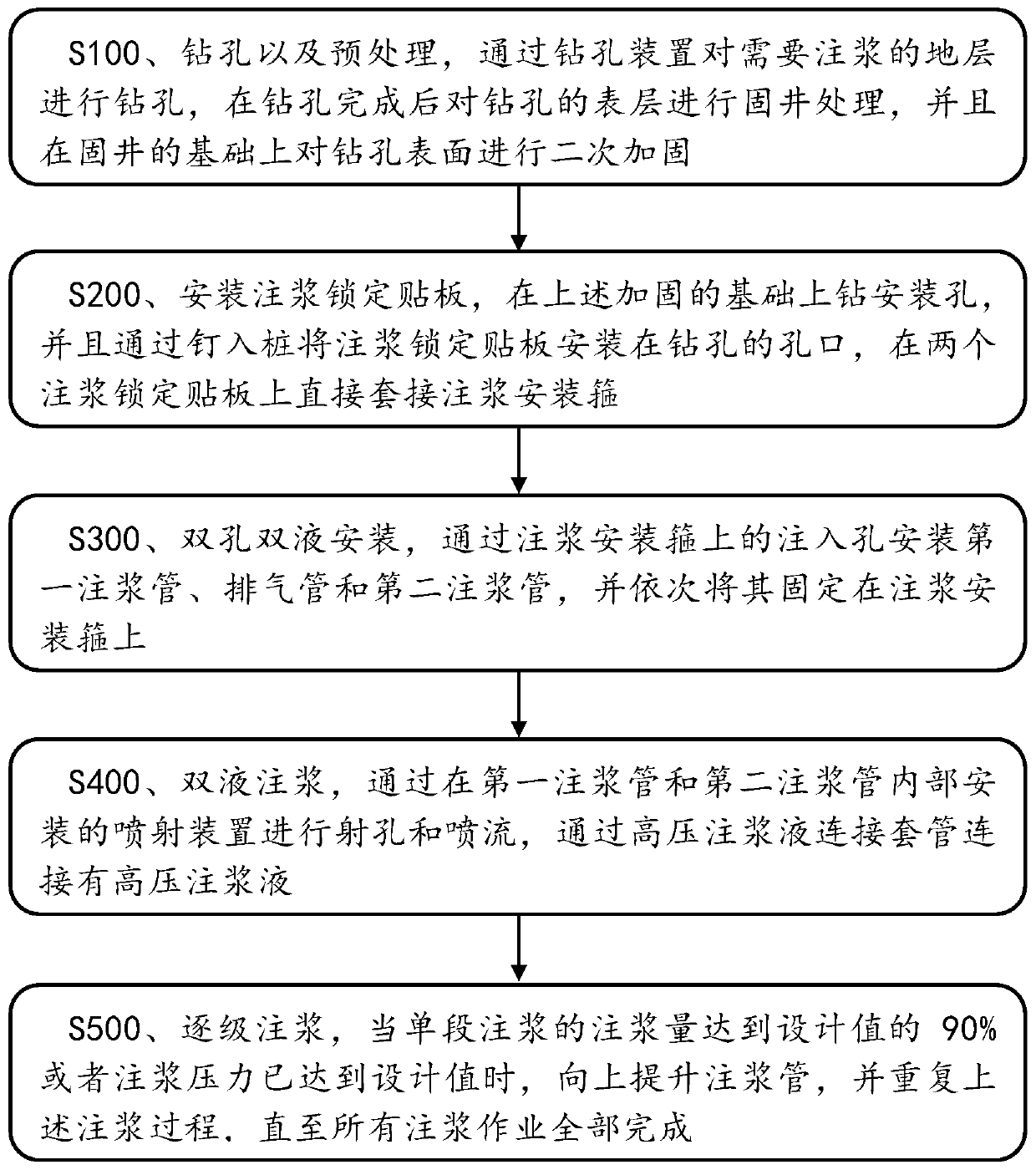

[0034] Such as figure 1 As shown, the present invention provides a kind of two-hole two-fluid grouting method, comprises the steps:

[0035] S100. Drilling and pretreatment: Drilling the stratum that needs grouting through the drilling device, performing cementing treatment on the surface of the drilled hole after the drilling is completed, and performing secondary treatment on the surface of the drilled hole on the basis of the cementing. For secondary reinforcement, the depth of cementing is not less than 10m, and the extended length of solidification on the surface is 3m with the center of the borehole as the center;

[0036] S200. Install the grouting locking plate, drill the installation hole on the above-mentioned reinforced foundation, and install the grouting locking plate on the opening of the drilled hole by nailing the pile, and directly socket the two grouting locking plates grouting mounting hoop;

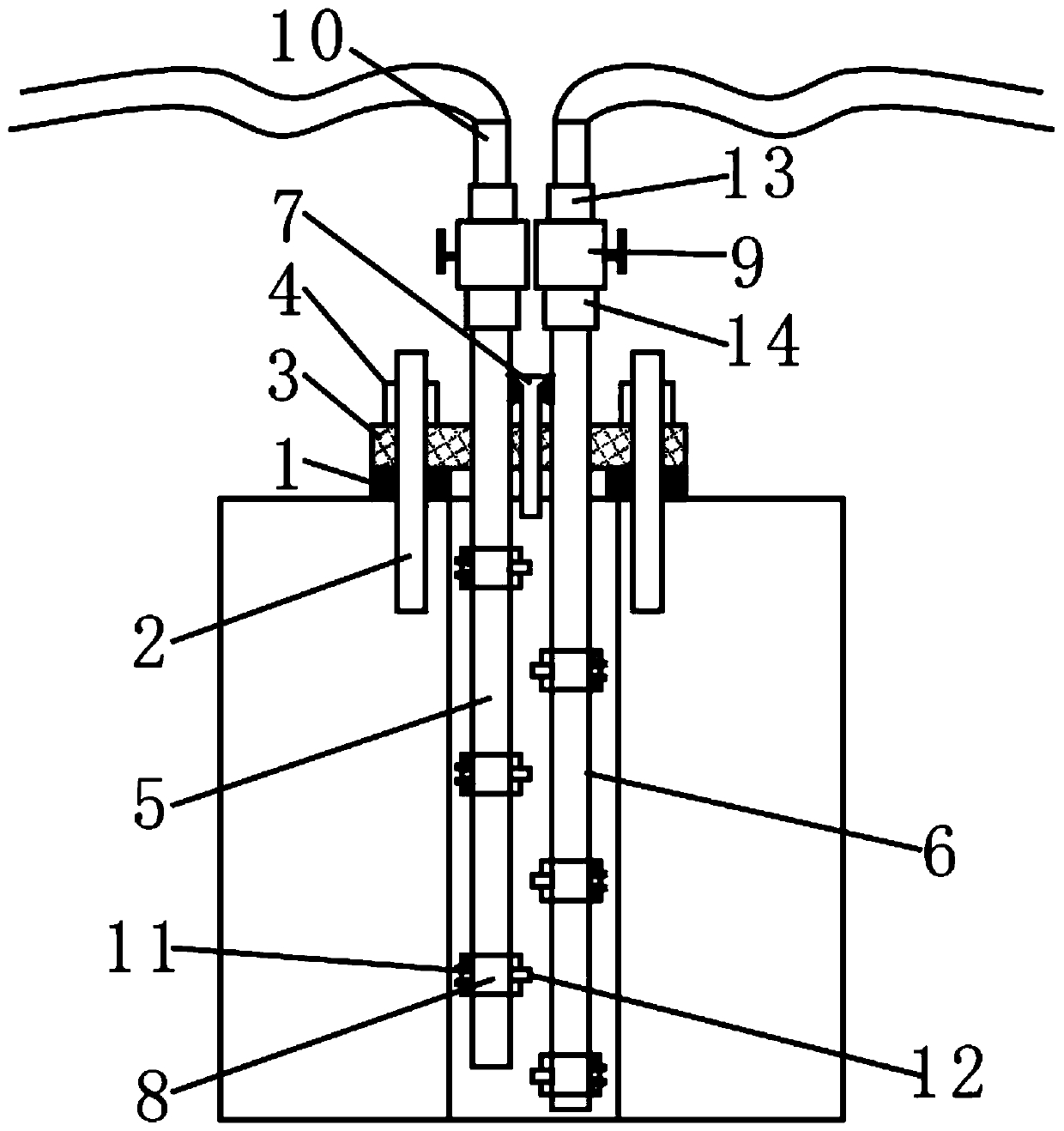

[0037] S300, double hole double liquid installation, install th...

Embodiment 2

[0045] Such as figure 1 As shown, the present invention provides a kind of two-hole two-fluid grouting method, comprises the steps:

[0046] S100. Drilling and pretreatment: Drilling the stratum that needs grouting through the drilling device, performing cementing treatment on the surface of the drilled hole after the drilling is completed, and performing secondary treatment on the surface of the drilled hole on the basis of the cementing. For secondary reinforcement, the depth of cementing shall not be less than 10m, and the extension length of solidification on the surface shall be 3.5m in radius with the borehole as the center;

[0047] S200. Install the grouting locking plate, drill the installation hole on the above-mentioned reinforced foundation, and install the grouting locking plate on the opening of the drilled hole by nailing the pile, and directly socket the two grouting locking plates grouting mounting hoop;

[0048] S300, double hole double liquid installation,...

Embodiment 3

[0056] Such as figure 1 As shown, the present invention provides a kind of two-hole two-fluid grouting method, comprises the steps:

[0057] S100. Drilling and pretreatment: Drilling the stratum that needs grouting through the drilling device, performing cementing treatment on the surface of the drilled hole after the drilling is completed, and performing secondary treatment on the surface of the drilled hole on the basis of the cementing. For secondary reinforcement, the depth of cementing is not less than 10m, and the extended length of solidification on the surface is 4m in radius with the borehole as the center;

[0058] S200. Install the grouting locking plate, drill the installation hole on the above-mentioned reinforced foundation, and install the grouting locking plate on the opening of the drilled hole by nailing the pile, and directly socket the two grouting locking plates grouting mounting hoop;

[0059] S300, double hole double liquid installation, install the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com