Exterior window lintel structure

A technology for lintels and external windows, applied to truss structures, joists, girders, etc., can solve the problems of excessive heat transfer coefficient of external window lintels, reduce heat transfer coefficients, increase construction costs, and facilitate heat preservation energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

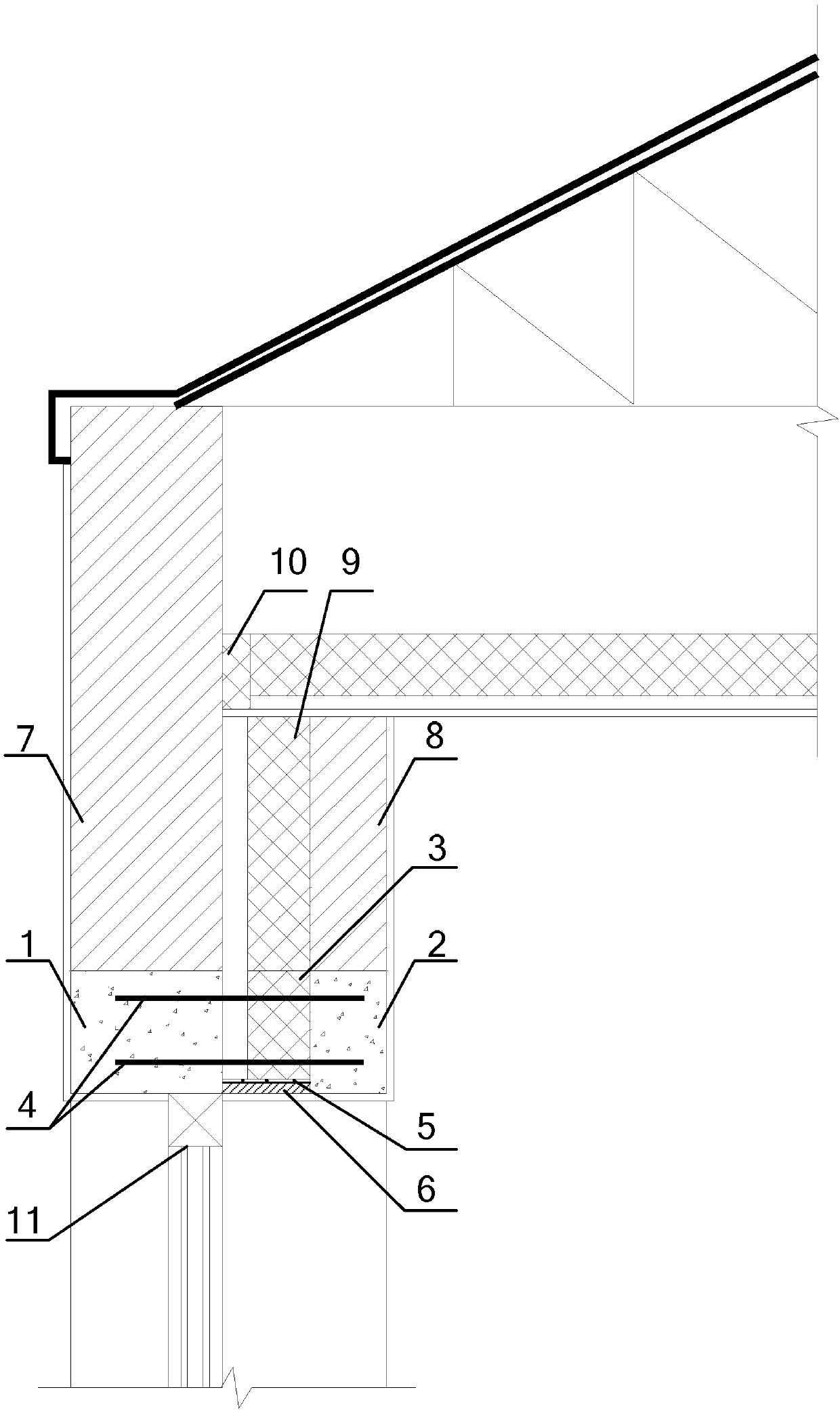

[0014] refer to figure 1 Describe this embodiment in detail, an outer window lintel structure described in this embodiment, the structure includes an outer beam 1, a lintel insulation layer 3 and an inner beam 2;

[0015] The outer beam 1 is fixed between the top of the outer window frame and the outer wall 7, and the thickness is the same as that of the outer wall 7,

[0016] The lintel insulation layer 3 is fixed between the top of the outer window frame and the wall insulation layer 9,

[0017] The inner beam 2 is fixed between the top of the window hole and the inner wall 8, and the thickness is the same as that of the inner wall 8,

[0018] The bottom of the lintel insulation layer 3 is provided with a steel wire mesh 5, and the outer surface of the steel wire mesh 5 is coated with mortar 6,

[0019] The outer girder 1 and the inner girder 2 are connected by two parallel reinforcement bars 4, and the reinforcement bars 4 are arranged horizontally.

[0020] The exterior...

specific Embodiment approach 2

[0021] Specific embodiment 2: This embodiment is to further illustrate a kind of outer window lintel structure described in specific embodiment 1. In this embodiment, when the lintel insulation layer 3 adopts non-hydrophobic thermal insulation materials, in order to avoid heat preservation If the layer is damp, the performance of the thermal insulation material will be reduced. There is a gap between the outer beam 1 and the lintel insulation layer 3. This gap is used as a moisture-proof air interlayer, and the distance between the outer beam 1 and the lintel insulation layer 3 is equal to the wall air space. layer thickness.

specific Embodiment approach 3

[0022] Specific embodiment three: this embodiment is a further description of a kind of exterior window lintel structure described in specific embodiment one. In this embodiment, a roof insulation layer 10 is laid between the outer wall 7 and the shed roof, and the roof insulation Layer 10 has a thickness of 50 mm. Laying the roof insulation layer 10 between the outer wall 7 and the roof can cut off the thermal bridge of this part, further achieving the purpose of insulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com