Active force application system for fiber fabric

A fiber fabric, active technology, applied in the field of fiber fabric active force application system, can solve the problems of low construction efficiency, long construction period, waste of high strength and superior performance, etc., and achieve the effect of avoiding fiber fabric damage, improving bearing capacity and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

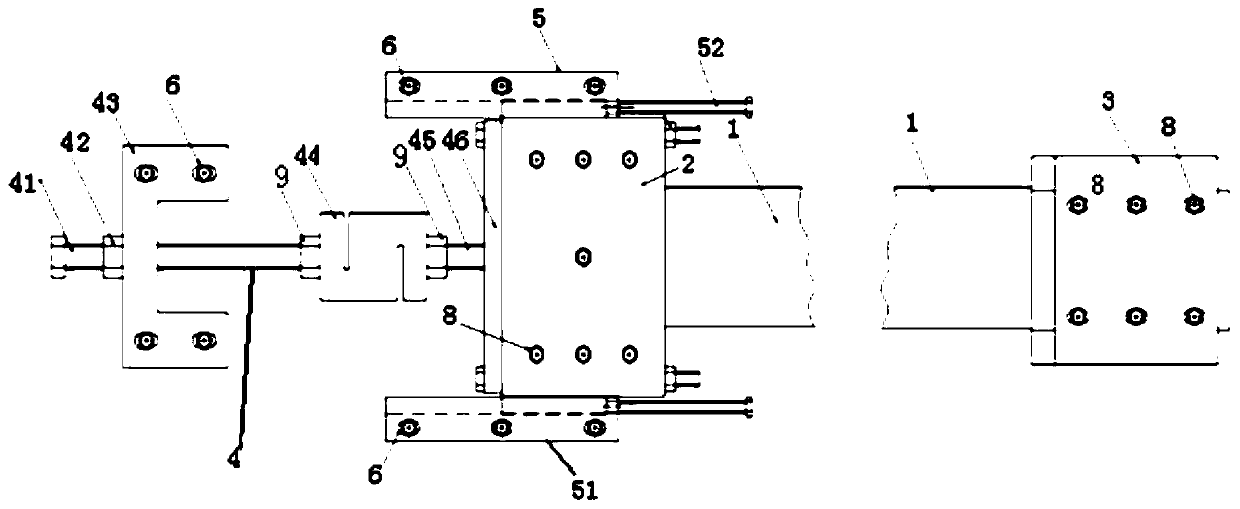

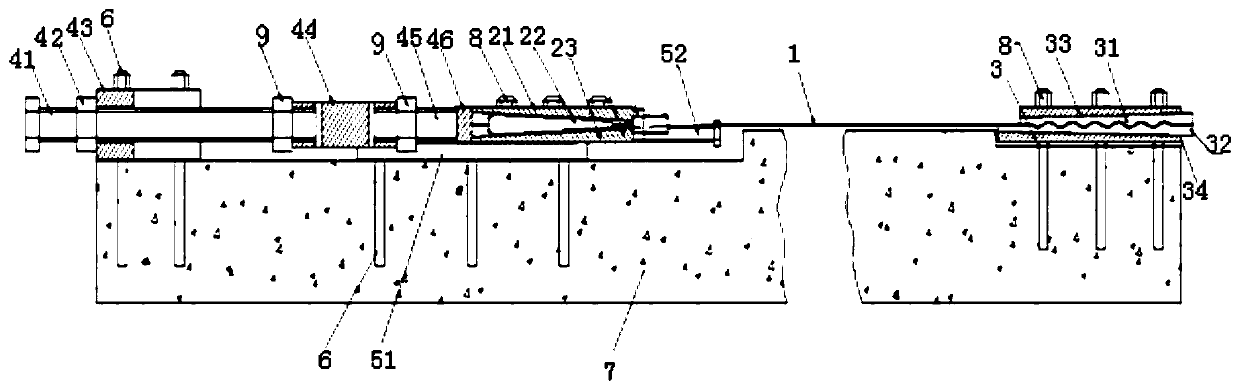

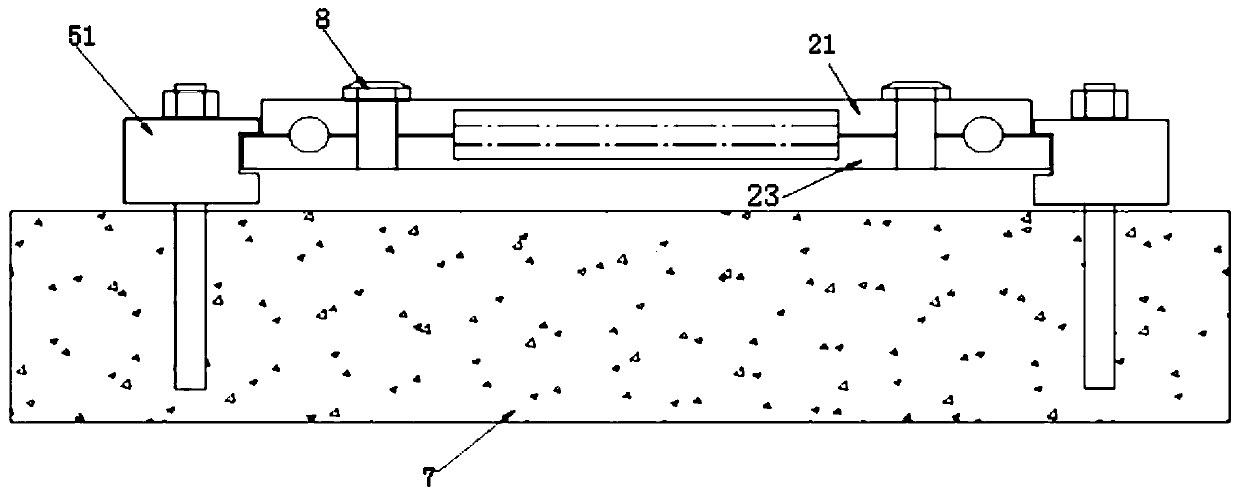

[0024] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0025] The fiber fabric active force application system of the present disclosure is used for the reinforcement of concrete beams, which includes a fiber fabric 1 , a first clamp 2 , a second clamp 3 , a force application member 4 and a fixing member 5 . Both ends of the fiber fabric 1 respectively fixed on the first fixture 2 and the second fixture 3, the force applying member 4 can exert force on the first fixture 2, so that the fiber fabric 1 is stretched, and the fixing member 5 is used to fix the stretched fiber fabric 1 s position.

[0026] In this embodiment, the fiber fabric 1 is clamped and fixed by the first clamp 2 and the second clamp 3, and the pre-stress is applied to the fiber fabric 1 through the force applying member 4, so that the fiber fabric 1 can fully exert its effective bearing capacity , so that its strength utilization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com