Aluminum alloy and preparation method and application thereof, connecting piece for body frame of vehicle, and electric vehicle

A technology of aluminum alloy and connector, applied in the field of aluminum alloy and its preparation, can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The method for preparing aluminum alloy provided in the second aspect of the present disclosure improves the traditional semi-solid forming process and develops a matching heat treatment process by improving the formula of the aluminum alloy, and solves the problem that the traditional preparation method cannot produce complex forming structures and high mechanical properties. The problem of aluminum alloy castings is solved, and the production cost is reduced at the same time.

[0043] The third aspect of the present disclosure provides an aluminum alloy prepared by the method of the second aspect of the present disclosure.

[0044] The fourth aspect of the present disclosure: provide the application of the aluminum alloy according to the first aspect or the third aspect of the present disclosure in vehicle body frame connectors.

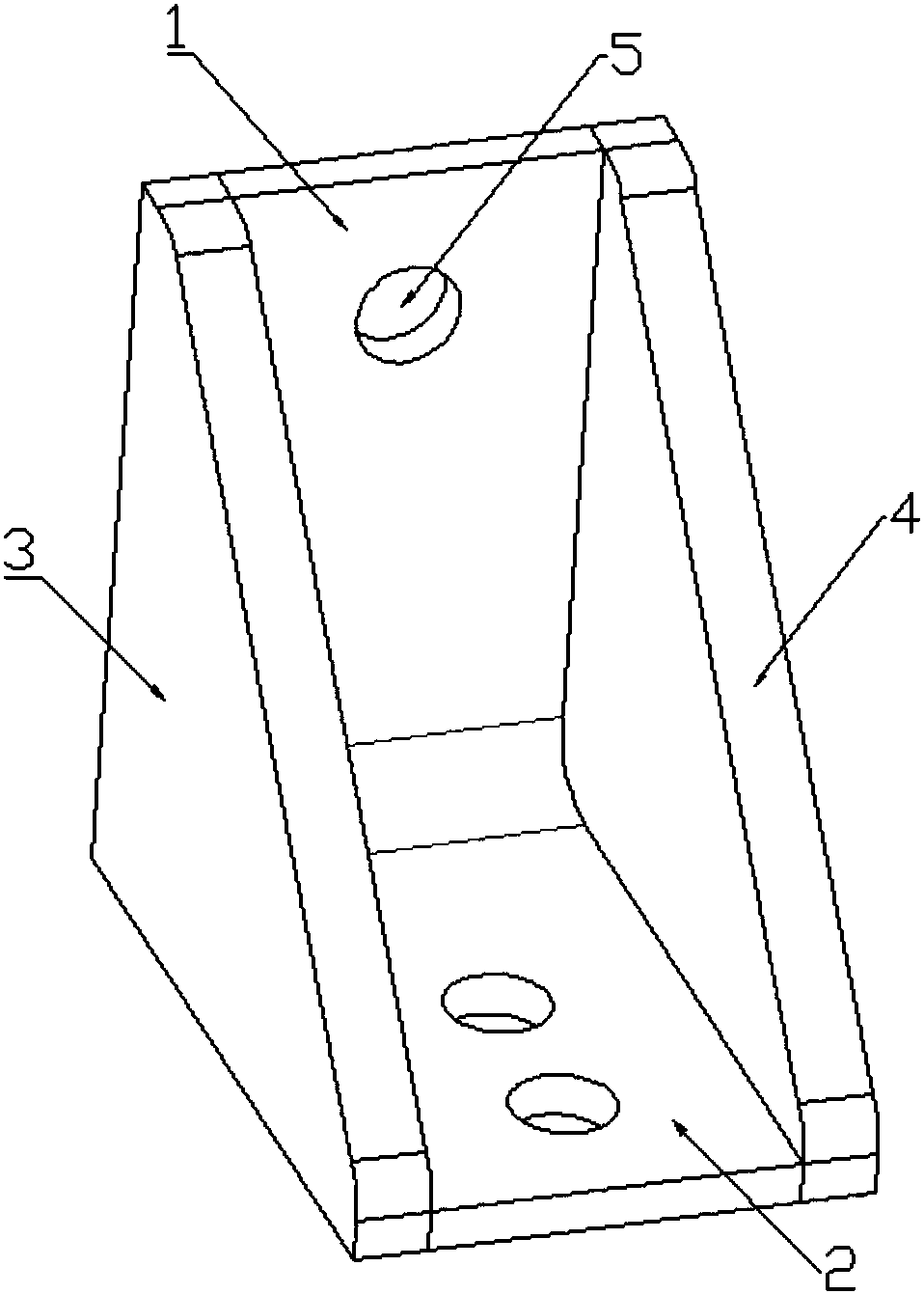

[0045] The fifth aspect of the present disclosure: provide a vehicle body frame connecting piece, the vehicle body frame connecting piece i...

Embodiment 1

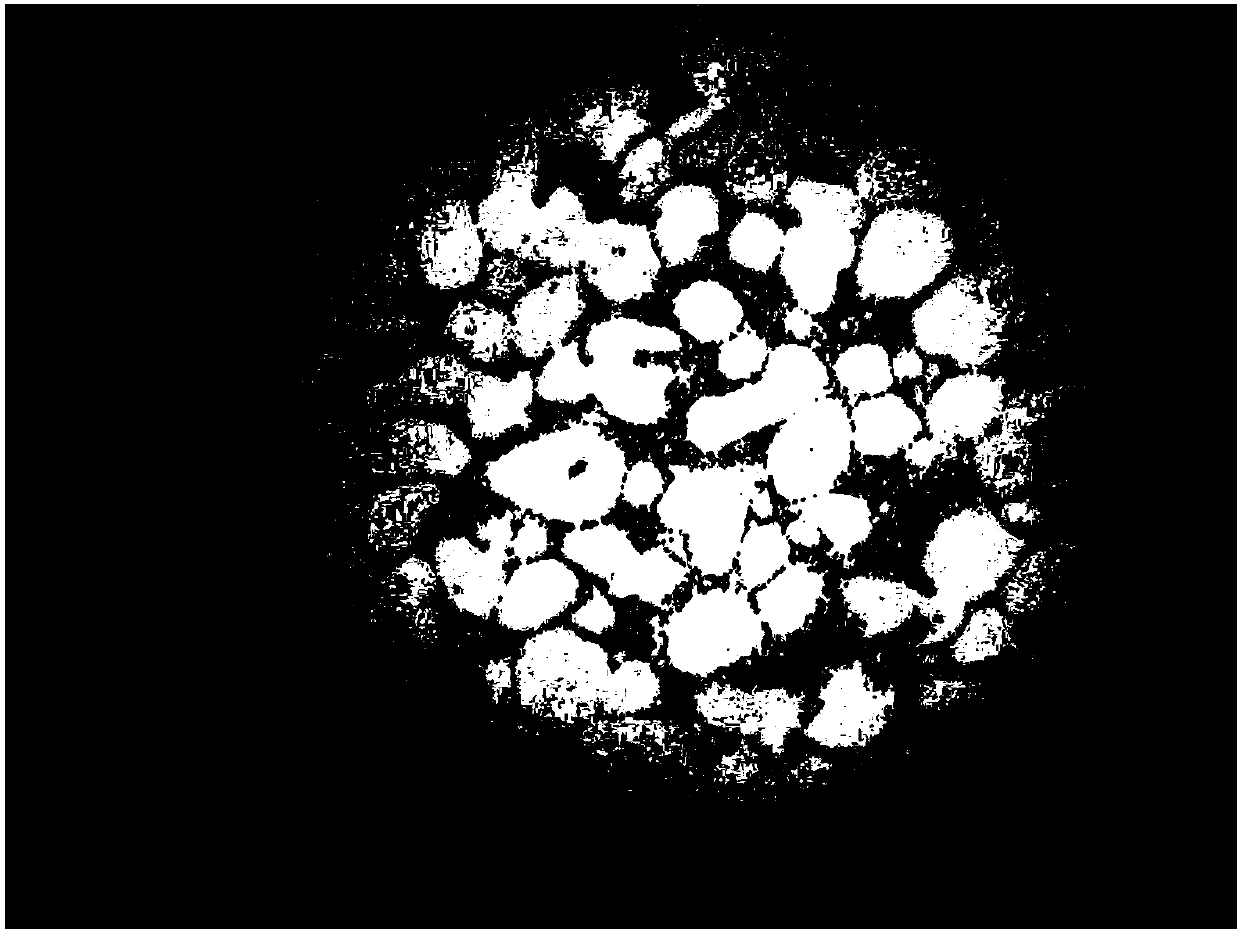

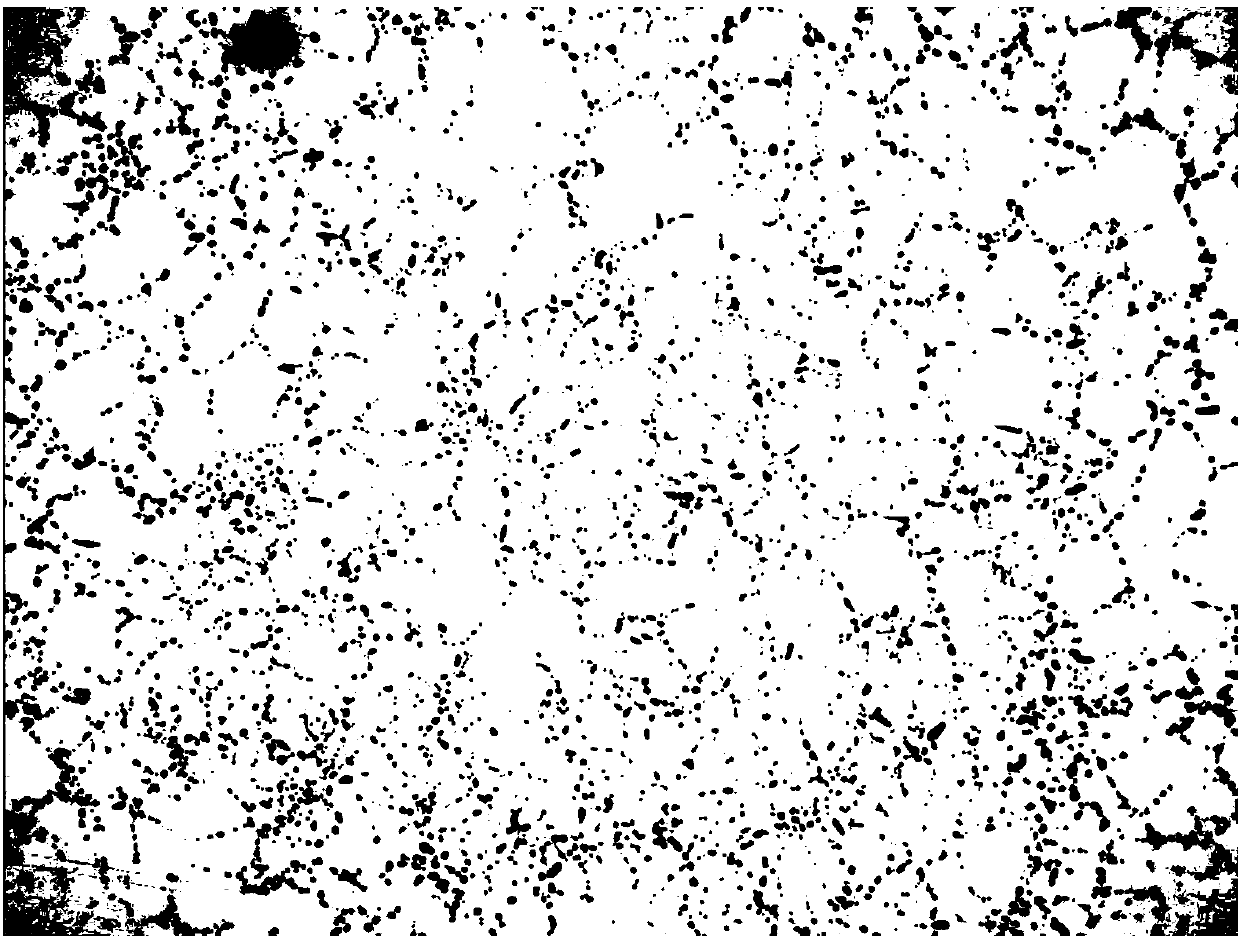

[0053] 6.3 parts by weight of Si, 0.55 parts by weight of Mg, 0.25 parts by weight of Cu, 0.1 parts by weight of Fe, 0.02 parts by weight of Mn, 0.15 parts by weight of Ti, 0.03 parts by weight of Zn and Al supplemented to 100 parts by weight Melt at 710°C for 8 hours; put the melted material in a crucible for ultrasonic vibration treatment and mechanical stirring treatment, the ultrasonic frequency is 30KHz, the ultrasonic vibration time is 9 seconds, the temperature is 690°C, and the ultrasonic vibration amplitude is 0.15 mm, the mechanical stirring speed is 1000r / min, and the mechanical stirring time is 9 seconds; pour the stirred material into the barrel, and squeeze it into the mold with a bottom-up squeeze casting machine (650 tons of tonnage) , the pressure is 60MPa, the injection speed is 0.2m / s; after the die-casting treatment, the sample nozzle and slag bag are removed, and the solid solution treatment is carried out at 525°C for 9 hours, and then the natural aging tr...

Embodiment 2

[0055] 6.1 parts by weight of Si, 0.51 parts by weight of Mg, 0.3 parts by weight of Cu, 0.07 parts by weight of Fe, 0.03 parts by weight of Mn, 0.1 parts by weight of Ti, 0.04 parts by weight of Zn and Al supplemented to 100 parts by weight Melt at 710°C for 8 hours; put the melted material in a crucible for ultrasonic vibration treatment and mechanical stirring treatment, the ultrasonic frequency is 60KHz, the ultrasonic vibration time is 1 minute, the temperature is 690°C, and the ultrasonic vibration amplitude is 0.1 mm, the mechanical stirring speed is 200r / min, and the mechanical stirring time is 60 seconds; pour the stirred material into the barrel, and squeeze it into the mold with a bottom-up squeeze casting machine (450 tons of tonnage) , the pressure is 100MPa, the injection speed is 0.4m / s; after the die-casting treatment, the sample nozzle and slag bag are removed, and the solid solution treatment is carried out at 520°C for 9h, and then the natural aging treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com