Construction method of high formwork with arc-shaped structure

A technology of arc-shaped structure and construction method, which is applied in the direction of arch structure, dome structure, formwork/formwork/working frame, etc., and can solve the problems of large adjustment of formwork poles, large number of uses, and long construction time , to improve flexibility and assembly accuracy, simplify the installation process, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

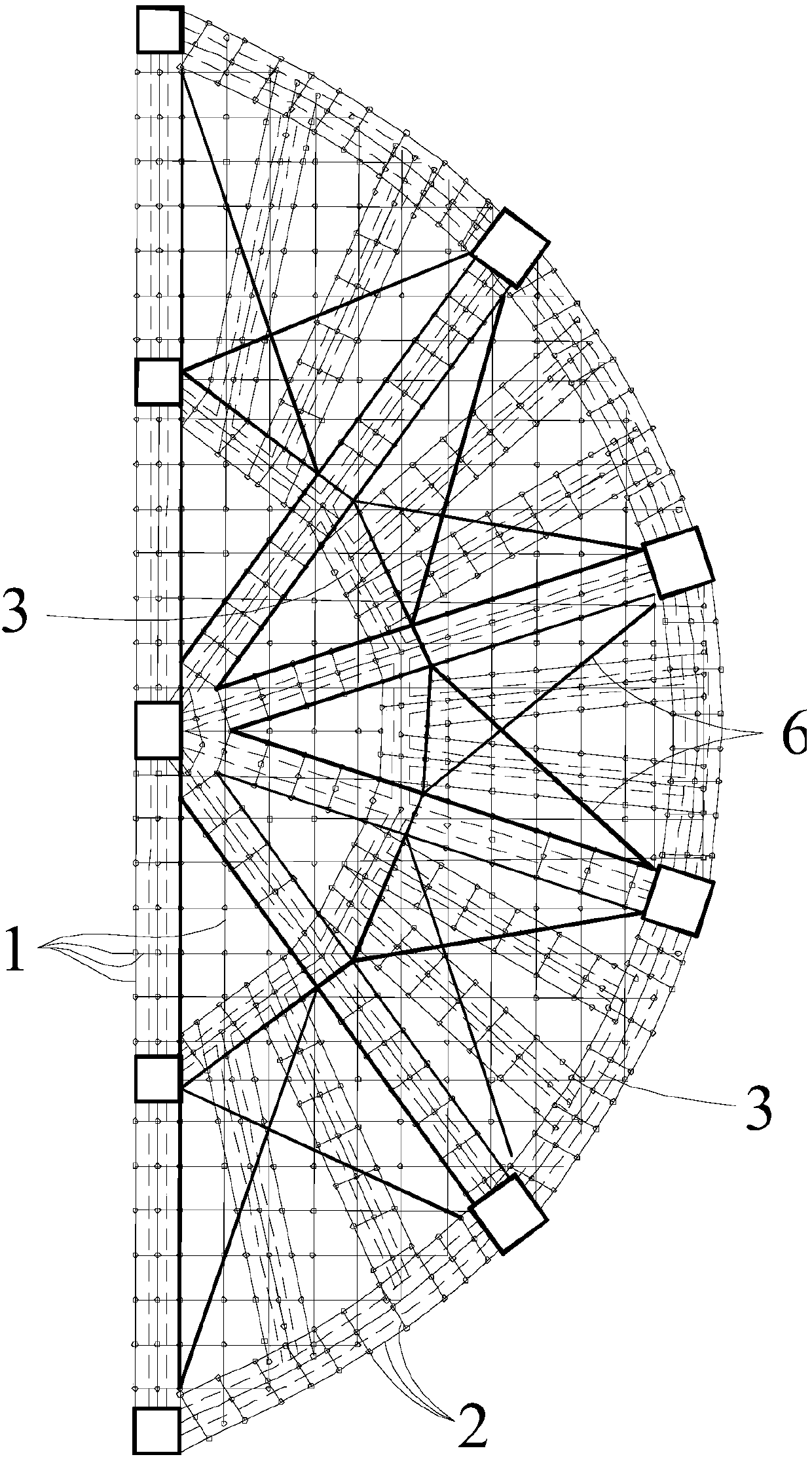

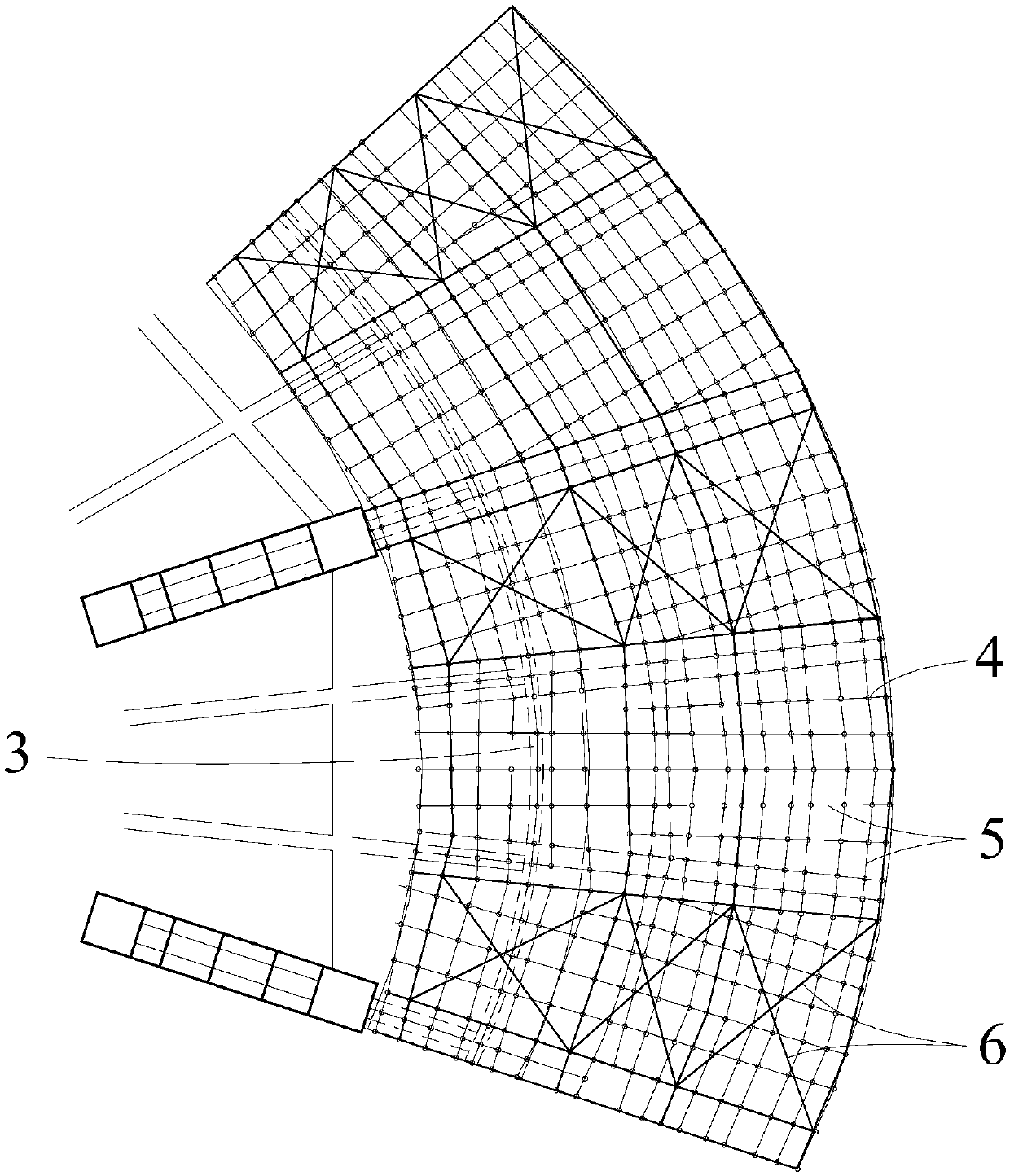

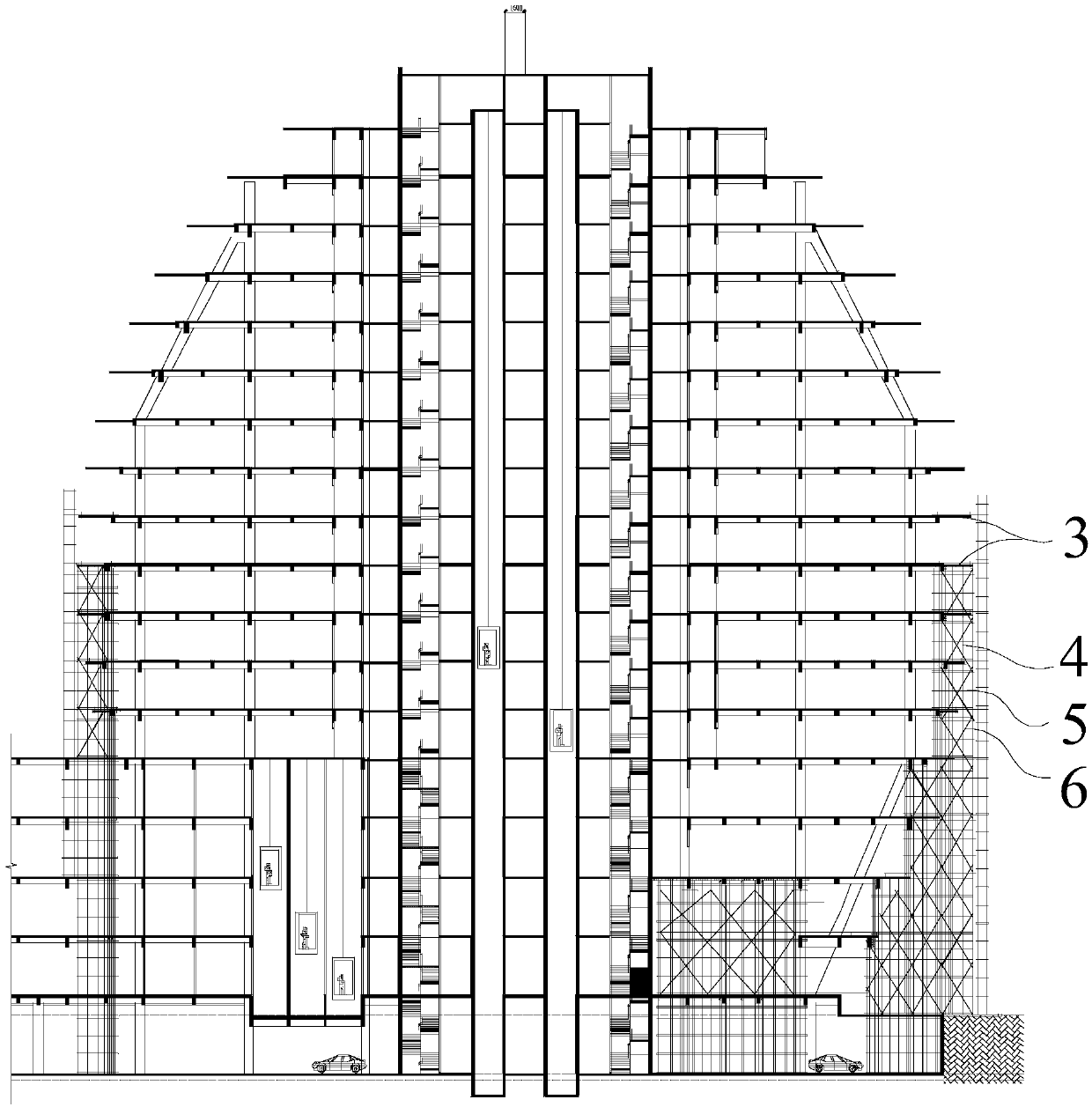

[0053] Such as Figure 2-4 As shown, a kind of curved structure 3 high support formwork construction method of the present invention is used for constructing the ellipsoid building of curved structure 3 such as the curved beam of variable curvature and curved plate etc. on the outside of construction, comprises the following steps :

[0054] A, make the template of arc structure 3, described template comprises side form and bottom form, and described side form and described bottom form are equally divided into standard module and non-standard module, and each described standard module and each number the non-standard modules;

[0055] B. Do data analysis and setting-out positioning according to the measurement reference points and design drawings;

[0056] C. According to the setting-out result, the formwork support of the high formwork is set, the vertical pole 4 of the formwork support is arranged along the position of the beam column to be poured, and the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com