Planetary gear with multiple sections of micro conical cylindrical face inner holes and design method thereof

A planetary gear, inner hole technology, applied in the direction of elements with teeth, belts/chains/gears, mechanical equipment, etc. load and other problems, to achieve good application prospects, avoid pressure eccentric load, and run smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

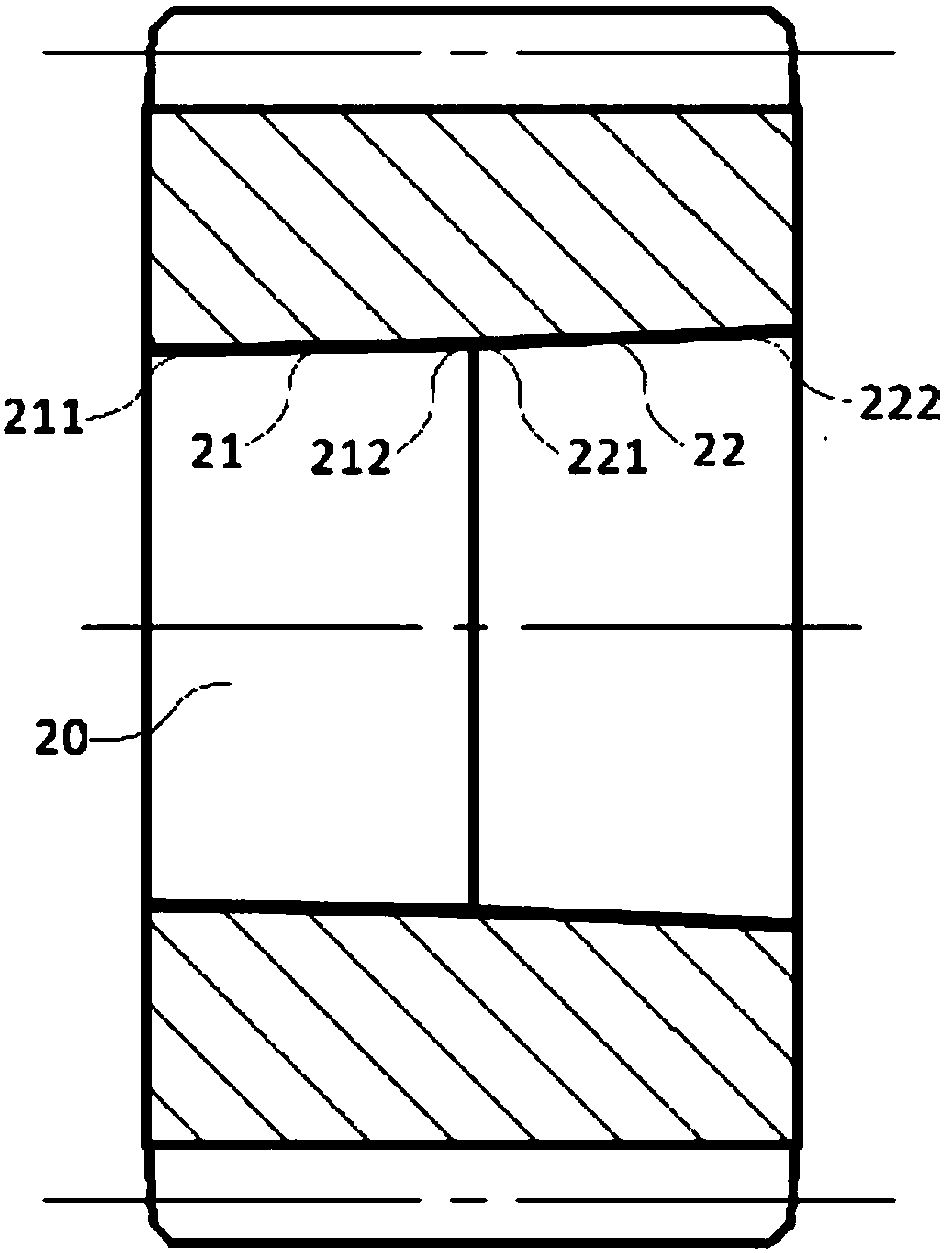

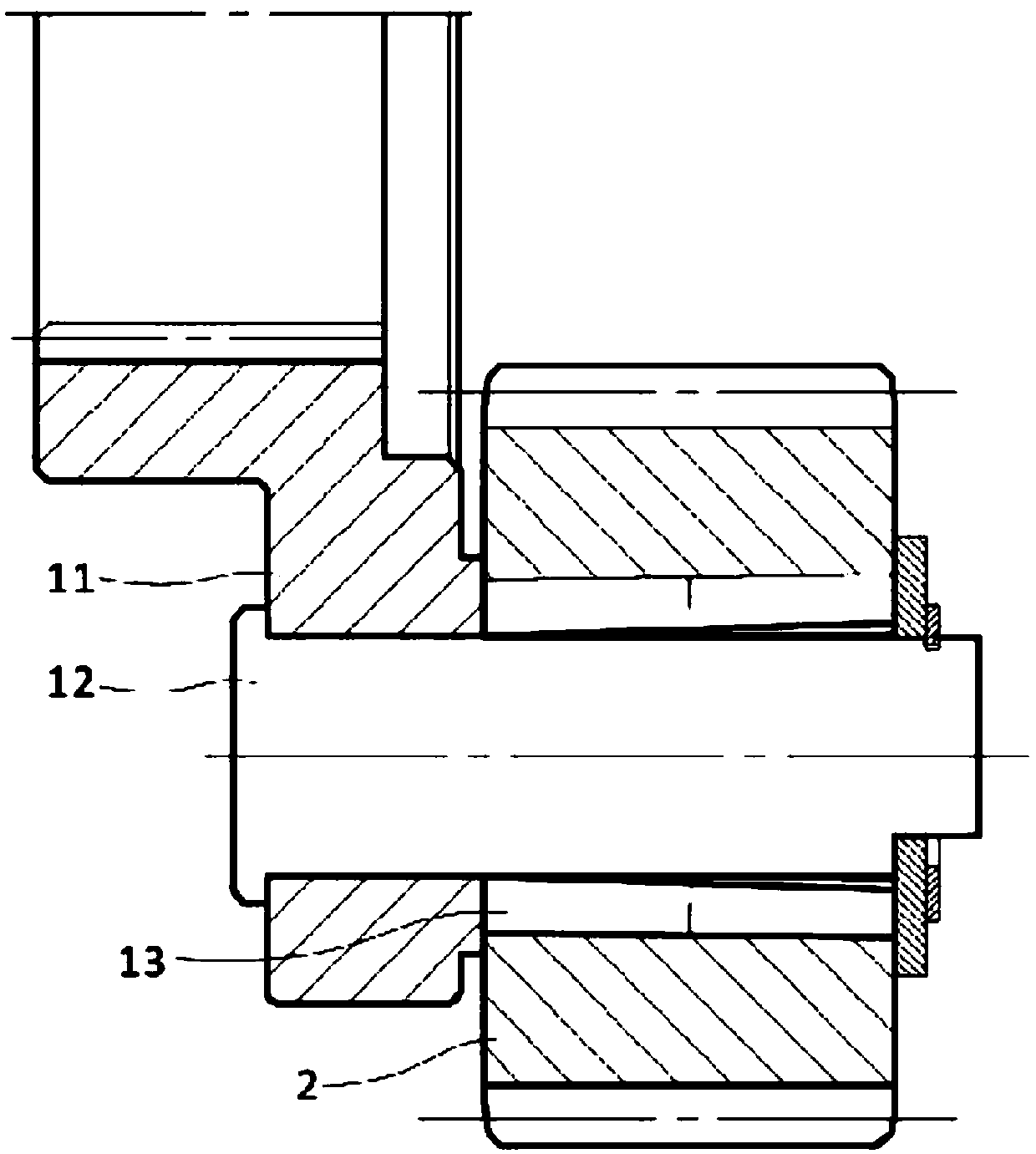

[0021] Embodiment 1: as figure 1 and figure 2 As shown, a planetary gear with two sections of micro-tapered cylindrical inner holes, its planetary gear 2 is set on the planetary carrier 11, wherein the planetary wheel shaft 12 is penetrated by the needle roller 13; the planetary gear 2 is set with a gear inner Hole 20, the gear inner hole 20 includes the first section 21 of the micro-tapered cylindrical surface and the second section 22 of the micro-tapered cylindrical surface. Section 22 is away from the other end of the planetary carrier, the inner diameter of the first section 21 of the micro-taper cylinder surface is smaller than the second section 22 of the micro-taper cylinder surface, and the big head of the first section of the micro-taper cylinder surface is in phase with the small head of the second section of the micro-taper cylinder surface connected with the same inner diameter.

[0022] A design method for a planetary gear provided with multi-stage micro-taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com