Method for measuring concentration of beryllium and beryllium compound in air in workplace

A compound and air technology, applied in the field of determination of the concentration of beryllium and its compounds in workplace air, can solve problems such as the inability to guarantee the accuracy and stability of trace beryllium, and the inability to meet the requirements of occupational health management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

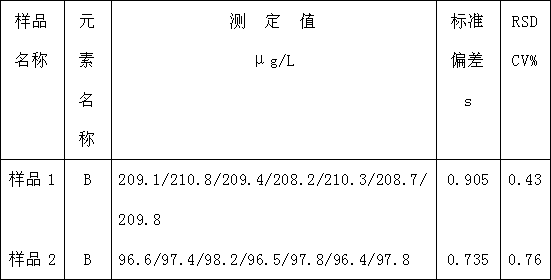

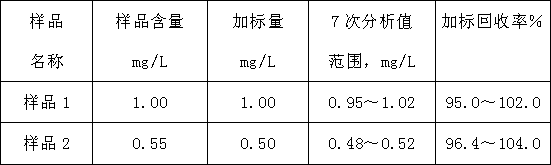

Examples

Embodiment Construction

[0019] The assay method of beryllium and its compound concentration in the workplace air of the present invention comprises the steps:

[0020] Step 1. Sample collection. Place the sampling clip with the microporous membrane installed at the sampling point to collect air samples for 15 minutes at a flow rate of 5 L / min or collect air samples for 2 to 8 hours at a flow rate of 1 L / min;

[0021] Step 2. After sampling, remove the microporous filter membrane from the sampling clip, fold the dust-contacting surface of the microporous filter membrane in half twice, put it in a clean plastic bag or paper bag, and transport and store it in a clean container. Simultaneously conduct blank test;

[0022] Step 3. Sample pretreatment. Place the sampled microporous membrane in a beaker, add 100ml of pure water and 10ml of 1+1 nitric acid digestion solution, and slowly heat and digest to ensure that the digestion solution does not boil. Slowly heat to nearly dry ;Remove and cool, and repea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com