A high-efficiency and safe screening equipment for iron powder impurity removal and classification

A screening equipment and miscellaneous classification technology, applied in the direction of sieve, solid separation, magnetic separation, etc., can solve the problems of increasing the difficulty of the subsequent process, uneven classification of iron powder, affecting the subsequent process, etc. Select the effect, improve the effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

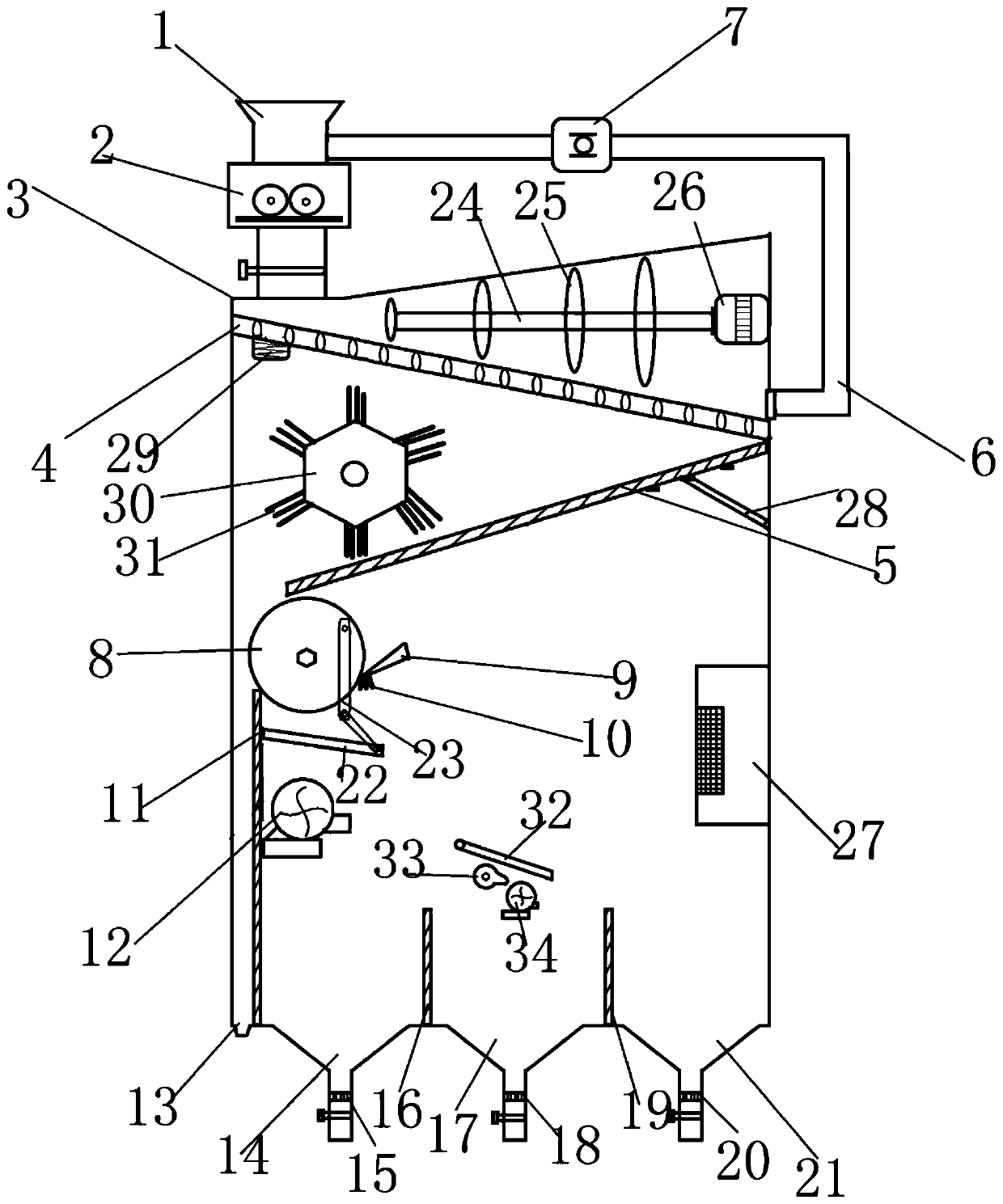

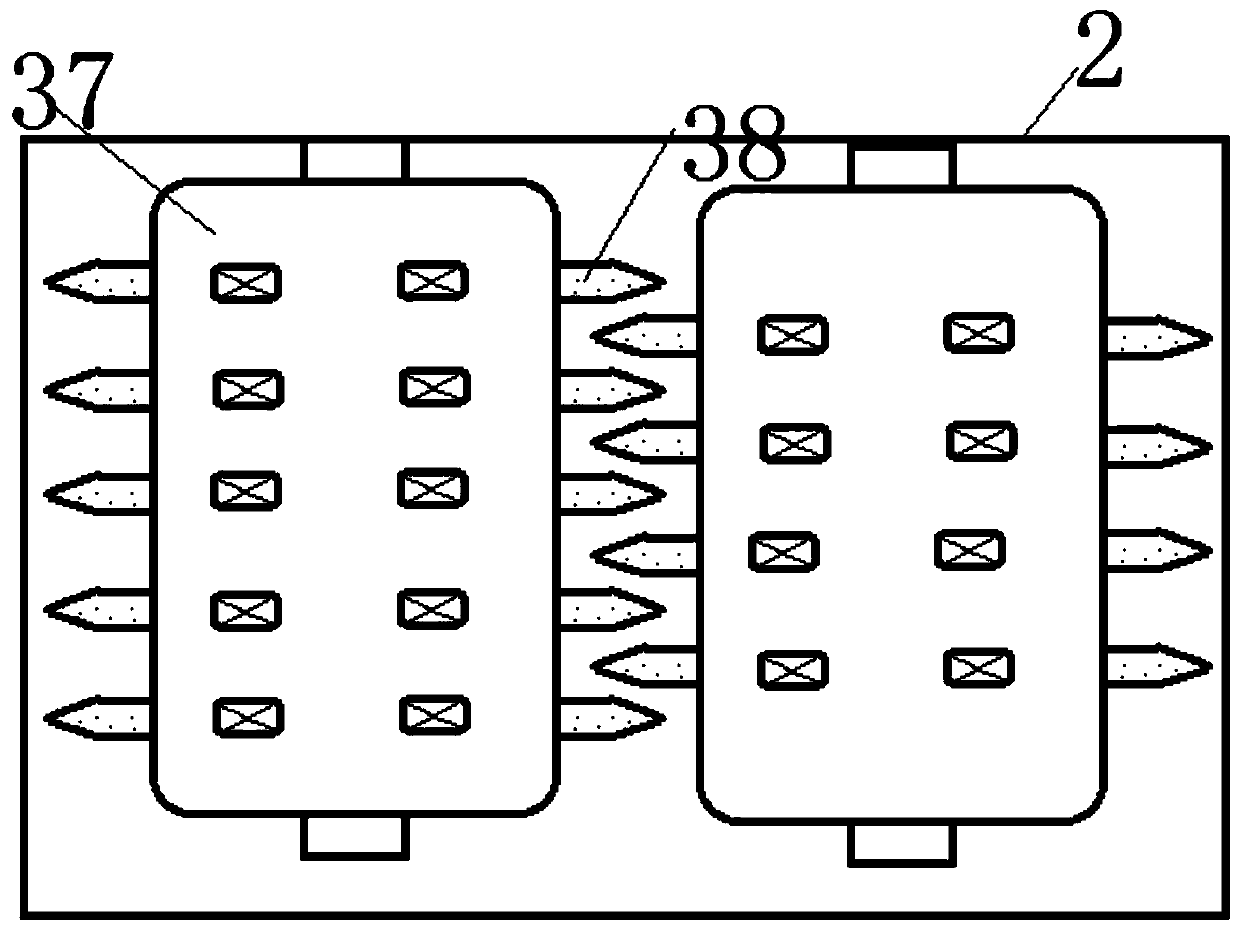

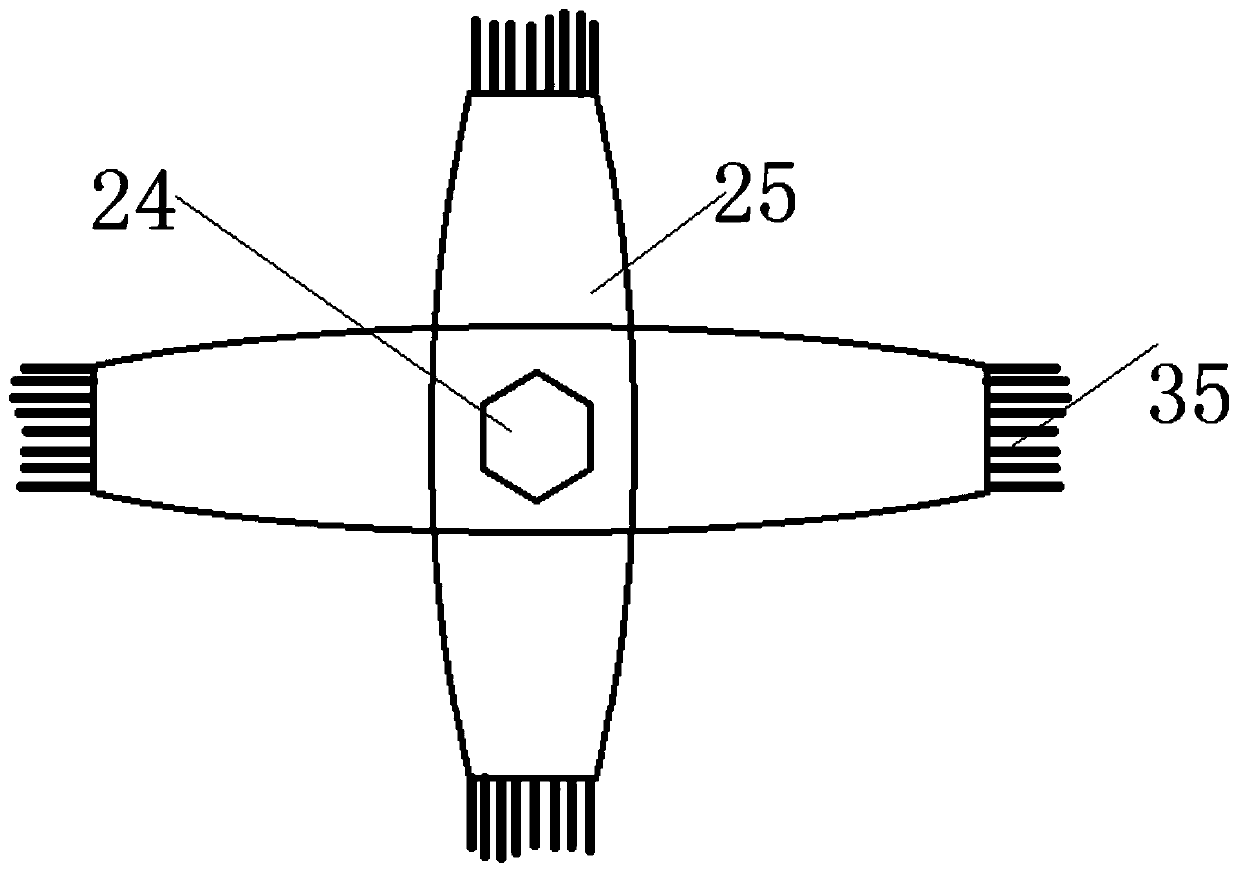

[0021] see Figure 1-5, a high-efficiency and safe screening equipment for removing impurities and classifying iron powder, including a feeding pipe 1, a pulverizer 2, a screening box 3, a vibrating screen 4, a guide plate 5, a return pipe 6, a solid transfer pump 7, an electromagnetic wheel 8, and a scraper 9 , clapboard 11, first winnowing machine 12, impurity outlet port 13, first-class iron powder outlet port 14, second-stage iron powder outlet port 17 and third-stage iron powder outlet port 21, the top of the screening box 3 and the feeding The pipe 1 is connected, and the pulverizer 2 is installed on the feeding pipe 1. Multiple sets of crushing cylinders 37 are installed in the pulverizer 2. The crushing cylinder 37 is provided with crushing teeth 38 that cooperate with each other and are staggered. The crushing cylinder 37 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com