Laser machining equipment for parallel machining

A laser processing and equipment technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of low processing efficiency and unsuitable processing of conical focused beams, and achieve the effect of improving laser processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

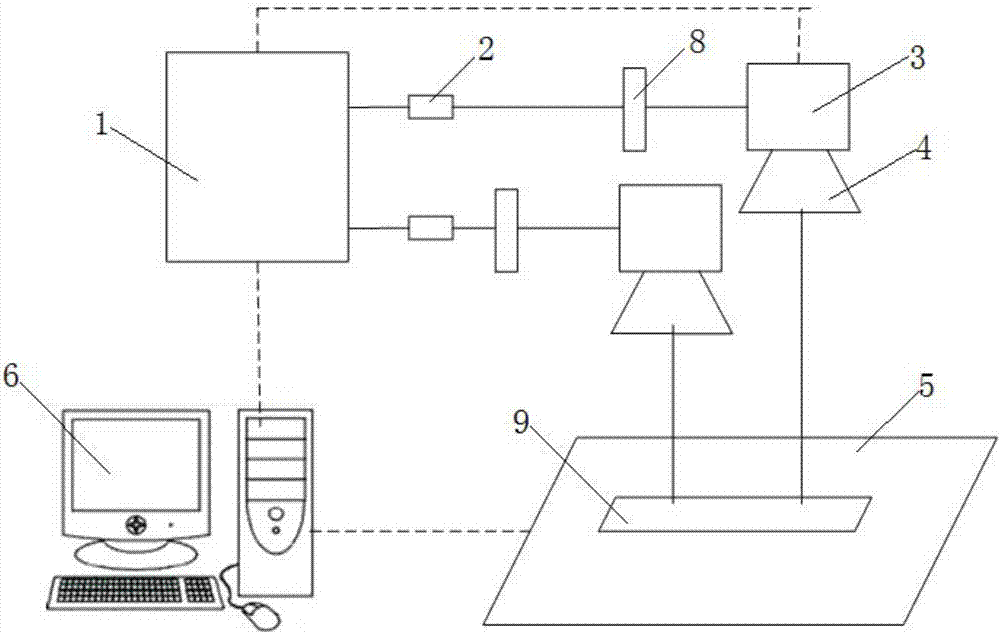

[0024] This embodiment provides a laser processing equipment for parallel processing, which includes a multi-beam laser 1 sequentially arranged along the optical path, a beam expander 2, a vibrating mirror 3 and a lens 4, and the light exit side of the lens 4 is provided with a The processing platform 5 that carries and moves the element 9 to be processed in the X-Y direction also includes a control mechanism 6 for controlling the multi-beam laser 1 and the vibrating mirror 3. The control mechanism 6 is a computer, and the multi-beam laser 1 is a multi-beam laser. One-way solid-state laser, as shown in the figure, it can produce multiple laser beams, the beam expander 2 is set in one-to-one correspondence with the multiple laser light paths generated by the laser, and each beam expander 2 is equipped with a vibrating mirror 3 correspondingly, each A lens 4 is correspondingly arranged behind each vibrating mirror 3 .

[0025] Wherein, the beam expander 2 is a beam expander, whi...

Embodiment 2

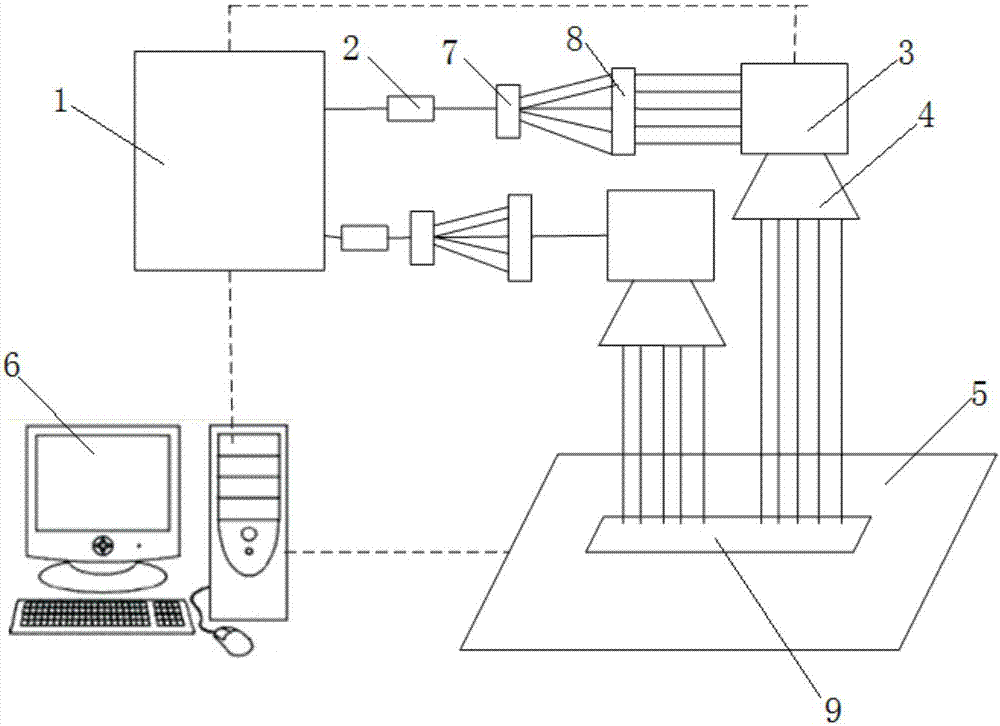

[0029] This embodiment provides a laser processing equipment for parallel processing, which includes a multi-beam laser 1 sequentially arranged along the optical path, a beam expander 2, a vibrating mirror 3 and a lens 4, and the light exit side of the lens 4 is provided with a The processing platform 5 that carries and moves the element 9 to be processed in the X-Y direction also includes a control mechanism 6 for controlling the multi-beam laser 1 and the vibrating mirror 3. The control mechanism 6 is a computer, and the multi-beam laser 1 is a multi-beam laser. One-way solid-state lasers can generate multiple laser beams. The beam expander 2 is provided in one-to-one correspondence with multiple laser light paths generated by the laser, and each beam expander 2 is followed by a vibrating mirror 3 , and each vibrating mirror 3 is followed by a lens 4 correspondingly.

[0030] Wherein, the beam expander 2 is a beam expander, which is used to expand the laser beam generated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com