Floating LNG production platform

A production platform and floating technology, applied to floating buildings, ships, etc., can solve the problems of ineffective development of offshore natural gas, insufficient technical solutions, high cost, etc., to achieve simple structure, stable operation of devices, and reduced installation and construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

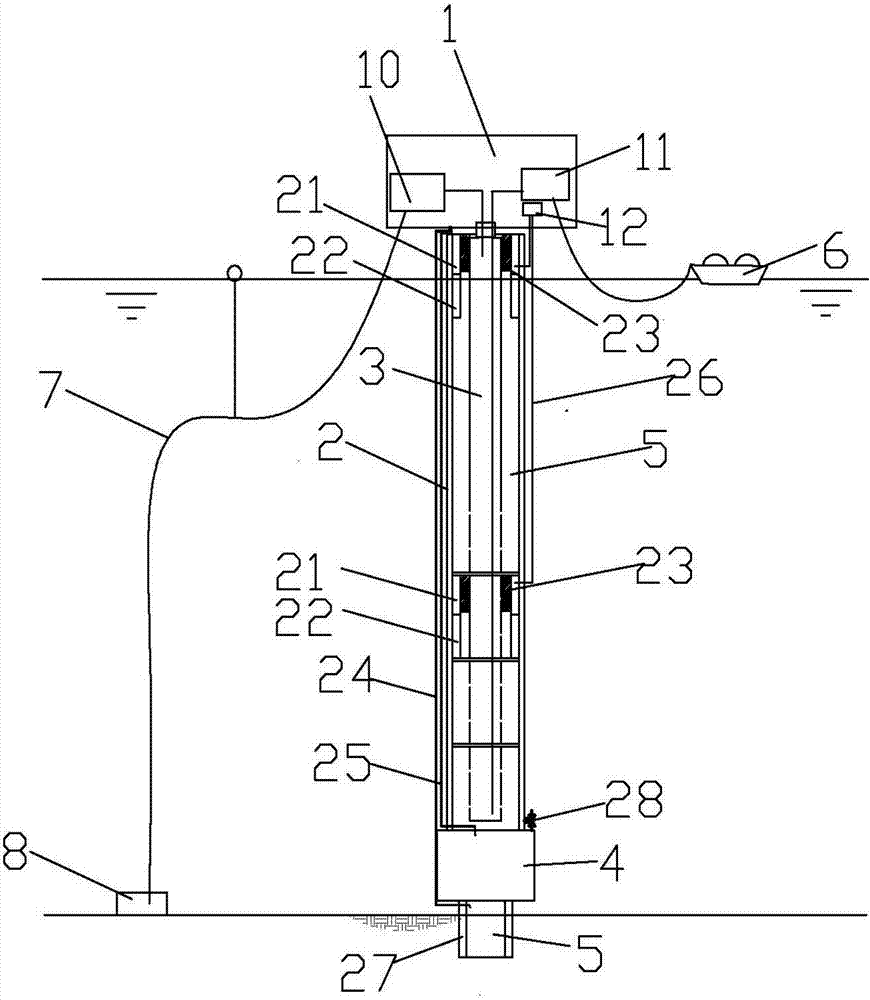

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

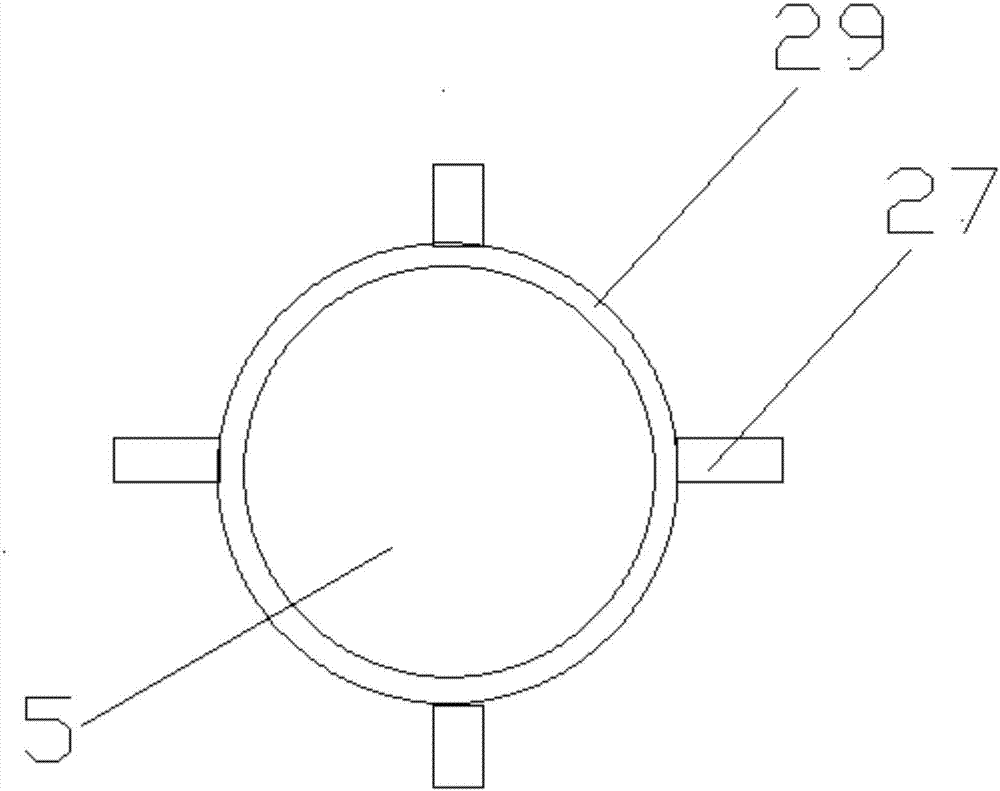

[0022] Such as Figure 1-Figure 2 Shown is a specific embodiment of a floating LNG production platform of the present invention, a floating LNG production platform comprising an upper module 1, a floating body 2 of a hollow structure, a fixed gravity cabin 4 fixedly connected to the bottom of the floating body 2, and The suction pile 5 fixedly connected with the fixed gravity chamber 4, the LNG liquid cargo tank 3 is arranged in the hollow part of the floating body 2, and a plurality of adjustable buoyancy chambers 21, fixed buoyancy chamber 22 and limit device 23 are arranged on the bulkhead of the floating body 2 , the adjustable buoyancy chamber 21, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com