Self-stratifying anti-pollution natural stone paint and preparation method thereof

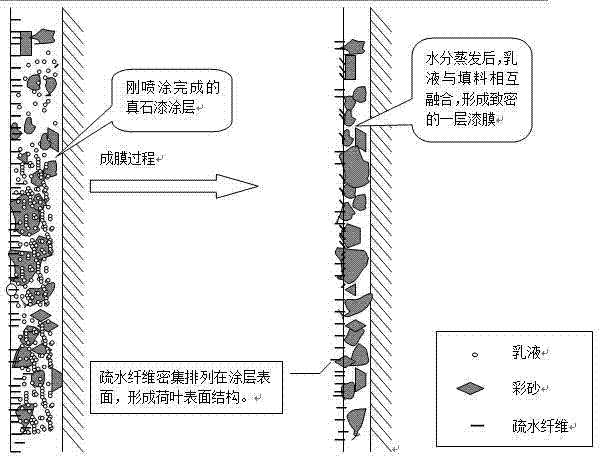

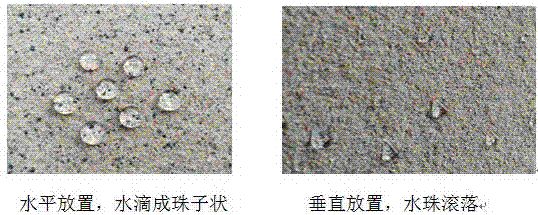

A real stone paint and self-layering technology, which is applied in the field of architectural decorative coating preparation, can solve the problems of poor stain resistance and achieve good stain resistance, prolong service life, and excellent stain resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Water 15.6%; Hydroxyethylcellulose (ES451) 0.15%; Defoamer (NXZ) 0.3%;

[0048] Multifunctional additive (AMP-95) 0.15%; wetting agent (LCN407) 0.1%;

[0049] Fungicide (HF) 0.15%; real stone paint emulsion (RS9765) 12.5%;

[0050] Hydrophobic agent (R / 75) 2%; film-forming aid (alcohol ester twelve) 0.65%;

[0051] Inorganic gel (SMP-HV2) 0.4%; hydrophobic fiber (polypropylene fiber powder) 3%;

[0052] Colored sand 65%.

[0053] Concrete preparation steps are as follows:

[0054] 1) Add an appropriate amount of water into the paint can, start stirring, and control the speed at 600 rpm;

[0055]2) Slowly add hydroxyethyl cellulose (ES451), defoamer (NXZ), multifunctional additive (AMP-95), wetting agent (LCN407), fungicide (HF), real stone paint emulsion (RS9765) in sequence , Hydrophobic agent (R / 75), film-forming aid (alcohol ester twelve), inorganic gel (SMP-HV2), keep the speed constant, stir for 18 minutes, prepare real stone paint glue, and set aside;

[005...

Embodiment 2

[0058] Water 10.4%; Hydroxyethylcellulose (ES451) 0.15%; Defoamer (NXZ) 0.3%;

[0059] Multifunctional additive (AMP-95) 0.15%; wetting agent (LCN407) 0.1%;

[0060] Fungicide (HF) 0.2%; real stone paint emulsion (RS9765) 16%;

[0061] Hydrophobic agent (R / 75) 0%; film-forming aid (alcohol ester twelve) 0.8%;

[0062] Inorganic gel (SMP-HV2) 0.4%; hydrophobic fiber (hydrophobic glass fiber powder) 5%;

[0063] Colored sand 66.5%.

[0064] Concrete preparation steps are as follows:

[0065] 1) Add an appropriate amount of water into the paint can, start stirring, and control the speed at 700 rpm;

[0066] 2) Slowly add hydroxyethyl cellulose (ES451), defoamer (NXZ), multifunctional additive (AMP-95), wetting agent (LCN407), fungicide (HF), real stone paint emulsion (RS9765) in sequence , film-forming aid (alcohol ester twelve), inorganic gel (SMP-HV2), keep the speed constant, stir for 15 minutes, and prepare real stone paint glue for use;

[0067] 3) Pump the real stone ...

Embodiment 3

[0069] Water 11.8%; Hydroxyethylcellulose (ES451) 0.2%; Defoamer (NXZ) 0.3%;

[0070] Multifunctional additive (AMP-95) 0.15%; wetting agent (LCN407) 0.1%;

[0071] Fungicide (HF) 0.15%; real stone paint emulsion (TX100) 23.5%;

[0072] Hydrophobic agent (R / 75) 0%; film-forming aid (alcohol ester twelve) 1%;

[0073] Inorganic gel (ATTAGEL 40) 0.3%; hydrophobic fiber (modified wollastonite powder) 4.5%;

[0074] Colored sand 58%.

[0075] Concrete preparation steps are as follows:

[0076] 1) Add an appropriate amount of water into the paint can, start stirring, and control the speed at 780 rpm;

[0077] 2) Slowly add hydroxyethyl cellulose (ES451), defoamer (NXZ), multifunctional additive (AMP-95), wetting agent (LCN407), fungicide (HF), real stone paint emulsion (TX100) in sequence , film-forming aid (alcohol ester twelve), inorganic gel (ATTAGEL40), keep the speed constant, stir for 12 minutes, prepare real stone paint glue, and set aside;

[0078] 3) Pump the real st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com