A kind of black electrochromic polymer material and its preparation method and application

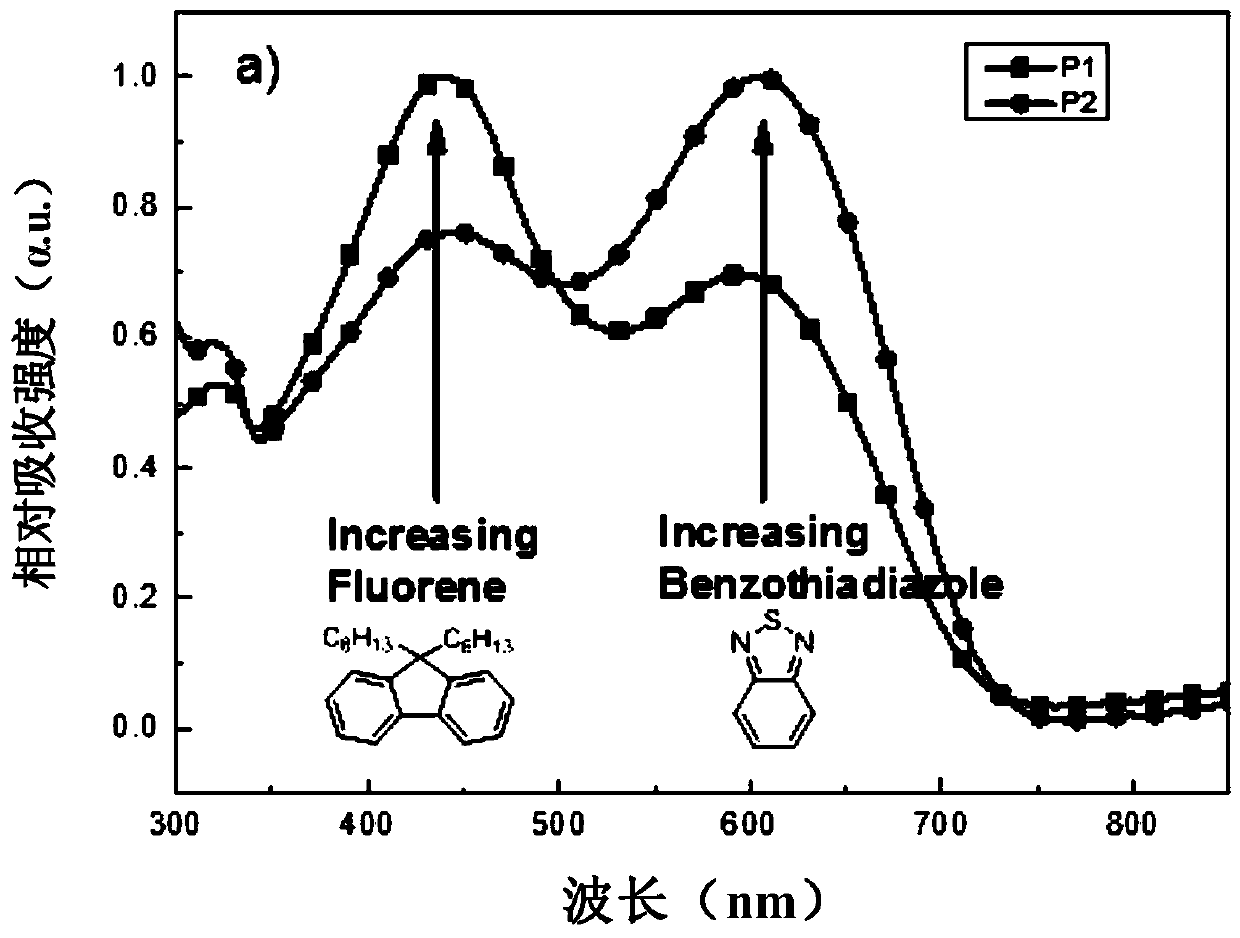

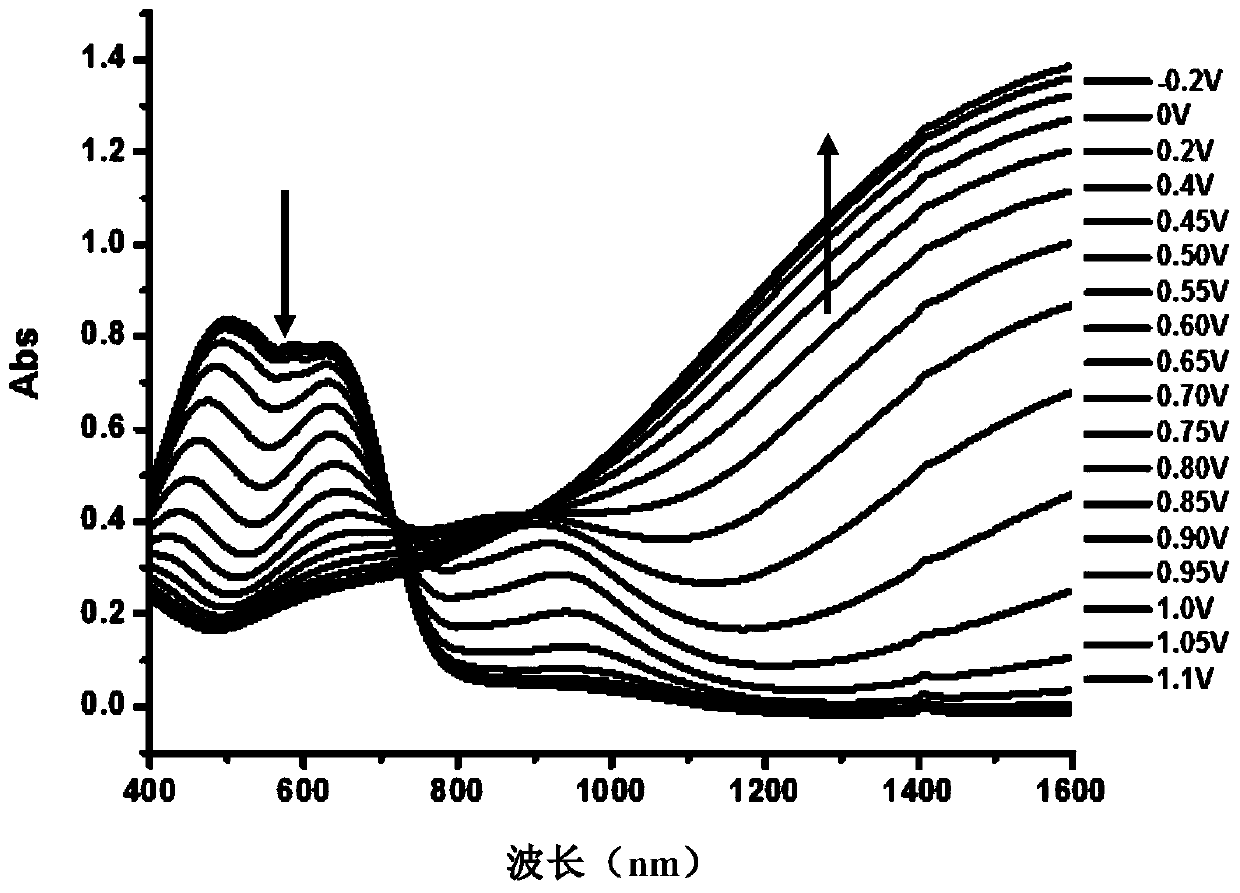

A polymer material and electrochromic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of insufficient absorption of visible light, insufficient blackness of polymers, and difficult absorption, etc., to achieve excellent electrochromic performance, The preparation method is simple and efficient, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

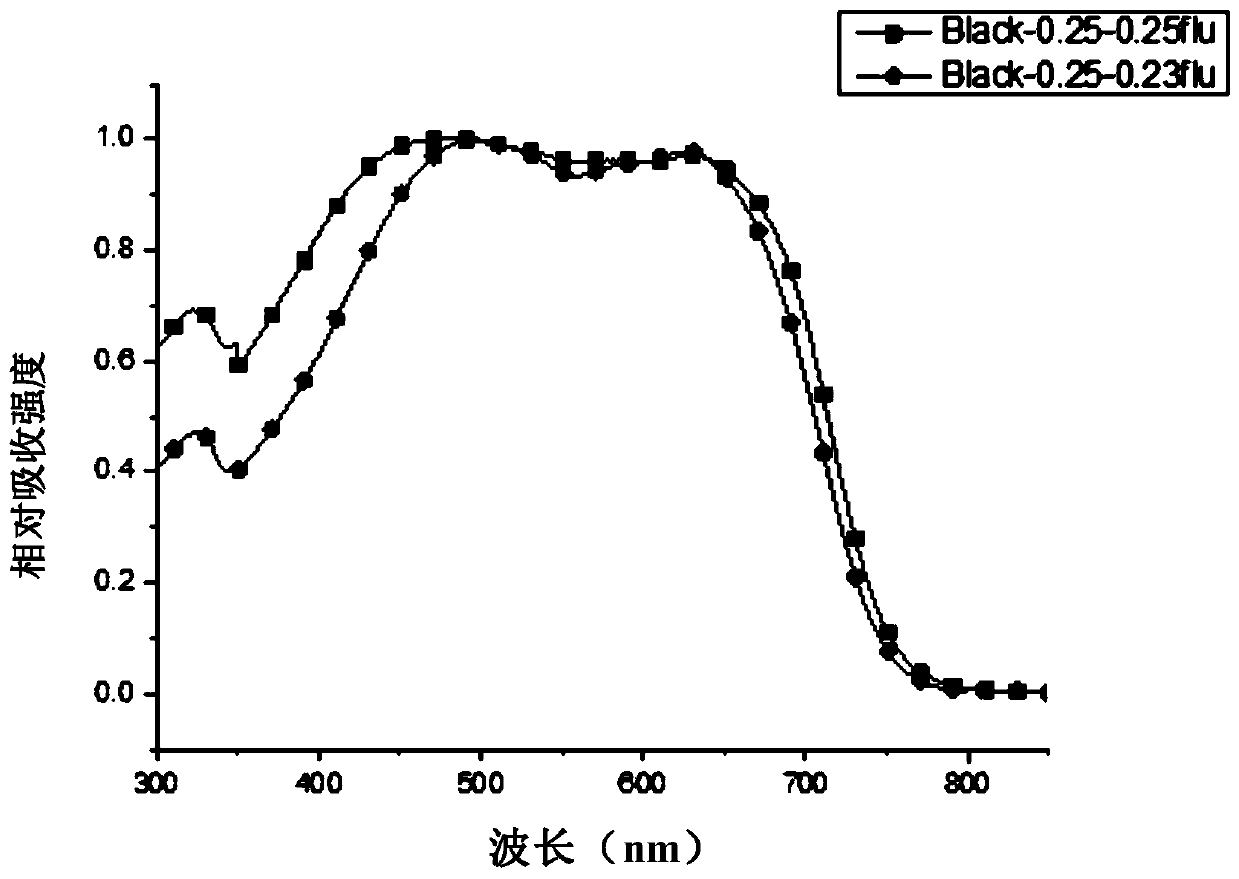

[0047] In this example, the polymer Black-0.25-0.23Flu was prepared through the following preparation process:

[0048]

[0049] The preparation method specifically comprises the following steps:

[0050] Add 3,3-bis(((2-ethylhexyl)oxy)methyl)-3,4-dioxo-2H-thiophene[3,4-b][1,4]dioxo to the Shrek tube Cyclo(0.32g, 1.0eq.), 4,7-dibromo[1,2,5]benzothiadiazole (0.053g, 0.25eq.), 6,8-dibromo-3,3-bis( ((2-Ethylhexyl)oxy)methyl)-3,4-dioxo-2H-thiophene[3,4-b][1,4]dioxane (0.226g, 0.52eq.), 2, 7-dibromo-9,9-dihexyl-9H-fluorene (0.082g, 0.23eq.), potassium carbonate (0.261g, 2.6eq.), pivalic acid (0.022g, 0.3eq.), palladium acetate ( 0.0033g, 0.02eq.). Evacuate for 15 minutes, then fill back with nitrogen, and repeat the evacuation and nitrogen replacement operation three times. Bubble 7 mL of N-methylpyrrolidone with nitrogen for 15 min before adding it to the Shrek tube. Heated at 120° C. and reacted for 6 hours under the protection of nitrogen. The reaction solution was pour...

Embodiment 2

[0054] In this example, the polymer Black-0.25-0.25Flu was prepared through the following preparation process:

[0055]

[0056] The preparation method specifically comprises the following steps:

[0057] Add 3,3-bis(((2-ethylhexyl)oxy)methyl)-3,4-dioxo-2H-thiophene[3,4-b][1,4]dioxo to the Shrek tube Cyclo(0.22g, 1.0eq.), 4,7-dibromo[1,2,5]benzothiadiazole (0.037g, 0.25eq.), 6,8-dibromo-3,3-bis( ((2-Ethylhexyl)oxy)methyl)-3,4-dioxo-2H-thiophene[3,4-b][1,4]dioxane (0.149g, 0.5eq.), 2, 7-dibromo-9,9-dihexyl-9H-fluorene (0.061g, 0.25eq.), potassium carbonate (0.179g, 2.6eq.), pivalic acid (0.015g, 0.3eq.), palladium acetate ( 0.0022g, 0.02eq.). Evacuate for 15 minutes, then fill back with nitrogen, and repeat the evacuation and nitrogen replacement operation three times. Bubble 7 mL of N-methylpyrrolidone with nitrogen for 15 min before adding it to the Shrek tube. Heated at 120° C. and reacted for 6 hours under the protection of nitrogen. The reaction solution was poure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com