Rare-earth modified high strength aluminum alloy powder special for additive manufacturing

A technology for modification of aluminum alloy powder and rare earth, which is applied in the direction of additive processing, etc., can solve the problems affecting the overall performance of the formed parts, and the performance cannot be guaranteed, so as to improve the physical and chemical properties, refine the alloy grains, expand the The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

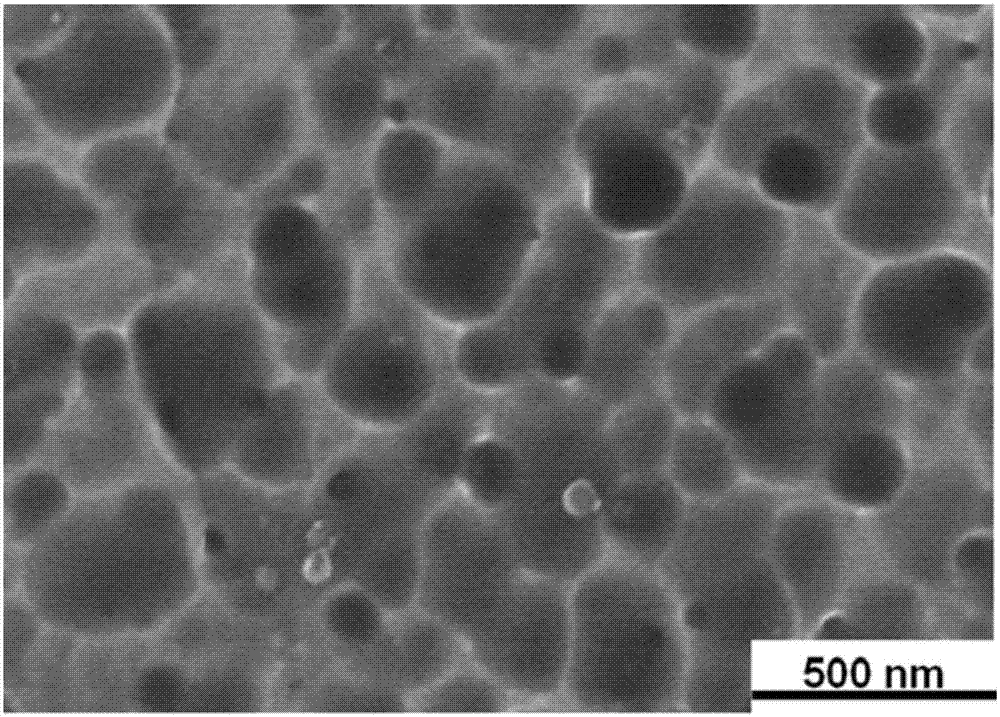

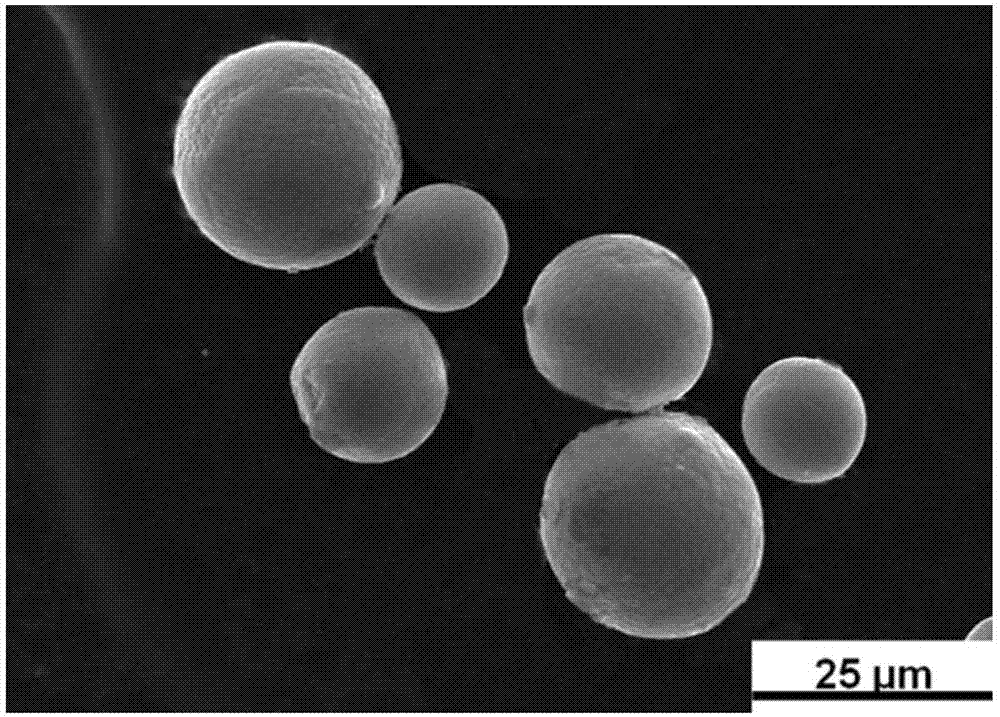

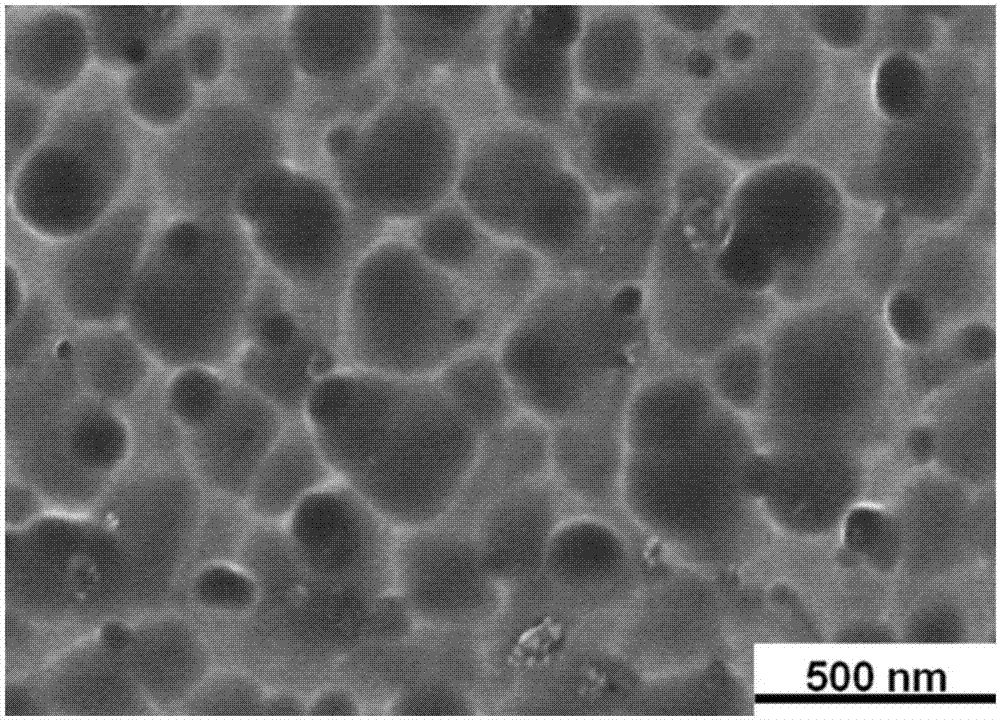

Image

Examples

Embodiment 1

[0057] Step (1): Ingredients

[0058] The mass percentages of the internal elements of a special rare earth modified high-strength aluminum alloy powder for additive manufacturing related to the present invention are: Mg: 4.2%, Zn: 0.5%, Ti: 0.35%, Zr: 0.2%, RE: 0.2% and the rest The amount of Al, where RE is a combination of rare earth elements, is Sc (0.15%) and Ce (0.05%). Weigh the pure metal or intermediate alloy powder according to the above ratio, the particle size of the powder should be less than 1mm, and mix it evenly with a ball mill.

[0059] Step (2): Ball milling and mixing of raw materials

[0060] Weigh the pure metal or intermediate alloy powder according to the above ratio, the particle size of the powder should be less than 1mm, and mix it evenly with a ball mill. The ball-to-material ratio is 10:1, the ball milling speed is 200rpm, and the ball milling time is 5h.

[0061] Step (3): Milling

[0062] The powder is made by gas atomization method, in which...

Embodiment 2

[0069] Step (1): Ingredients

[0070] The mass percentages of the internal elements of a special rare earth modified high-strength aluminum alloy powder for additive manufacturing related to the present invention are: Mg: 4.2%, Zn: 0.5%, Ti: 0.35%, Zr: 0.2%, RE: 0.2% and the rest The amount of Al, where RE is a combination of rare earth elements, is Sc (0.14%) and La (0.06%). Weigh the pure metal or intermediate alloy powder according to the above ratio, the particle size of the powder should be less than 1mm, and mix it evenly with a ball mill.

[0071] Step (2): Ball milling and mixing of raw materials

[0072] Weigh the pure metal or intermediate alloy powder according to the above ratio, the particle size of the powder should be less than 1mm, and mix it evenly with a ball mill. The ball-to-material ratio is 10:1, the ball milling speed is 200rpm, and the ball milling time is 5h.

[0073] Step (3): Milling

[0074] The powder is made by gas atomization method, in which...

Embodiment 3

[0081] Step (1): Ingredients

[0082]The mass percentages of the internal elements of a special rare earth modified high-strength aluminum alloy powder for additive manufacturing related to the present invention are: Mg: 4.2%, Zn: 0.5%, Ti: 0.35%, Zr: 0.2%, RE: 0.2% and the rest The amount of Al, where RE is a combination of rare earth elements, is Sc (0.12%), Nd (0.03%) and Yb (0.03%). Weigh the pure metal or intermediate alloy powder according to the above ratio, the particle size of the powder should be less than 1mm, and mix it evenly with a ball mill.

[0083] Step (2): Ball milling and mixing of raw materials

[0084] Weigh the pure metal or intermediate alloy powder according to the above ratio, the particle size of the powder should be less than 1mm, and mix it evenly with a ball mill. The ball-to-material ratio is 10:1, the ball milling speed is 200rpm, and the ball milling time is 5h.

[0085] Step (3): Milling

[0086] The gas atomization method is used to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com