Three-phase metering device and method for high-water-content low-yield oil well output liquid

A technology of metering device and oil well, which is used in surveying, earth-moving drilling, wellbore/well components, etc., can solve the problems of affecting the metering accuracy, large metering error, and limited field promotion, and achieves the goal of reducing the separation device and ensuring the accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

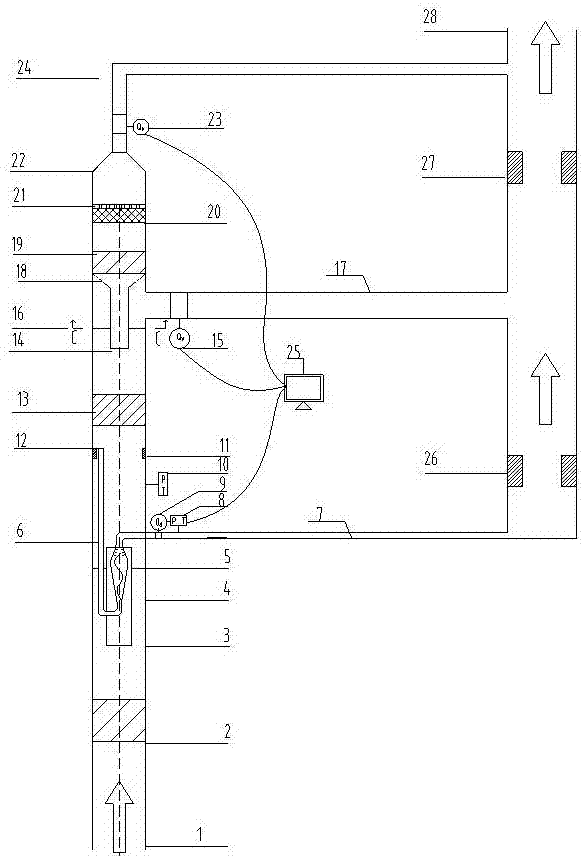

[0043] The oil well produced liquid flows into the oil well oil, gas and water three-phase automatic metering system of the present invention through the vertically installed liquid production inlet section 1. After the produced liquid flows through the cyclone device 2, the inflow is rectified into a gas core and an oil-water mixture. The outer ring adheres to the wall, and the gas core is taken out by the gas core sampling pipe 3 which is placed in the center of the pipeline for sampling according to the principle of isokinetic energy. It also includes a small amount of oil-water fluid. At this time, all the gas core and part of the liquid pass through the gas core sampling pipe 3. The gas-liquid cyclone separator 4 enters the gas-liquid cyclone separator 4 tangentially, and then rotates at a high speed into the gas-liquid cyclone separator 4 to realize the effective separation of gas and liquid by the centrifugal force and gravity generated by the rotation. The gas-liquid cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com