Superconductive thin film material and manufacturing method thereof

A technology of a superconducting thin film and a manufacturing method, which is applied in the manufacture/processing of superconducting devices, superconducting devices, superconducting parts, etc. The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

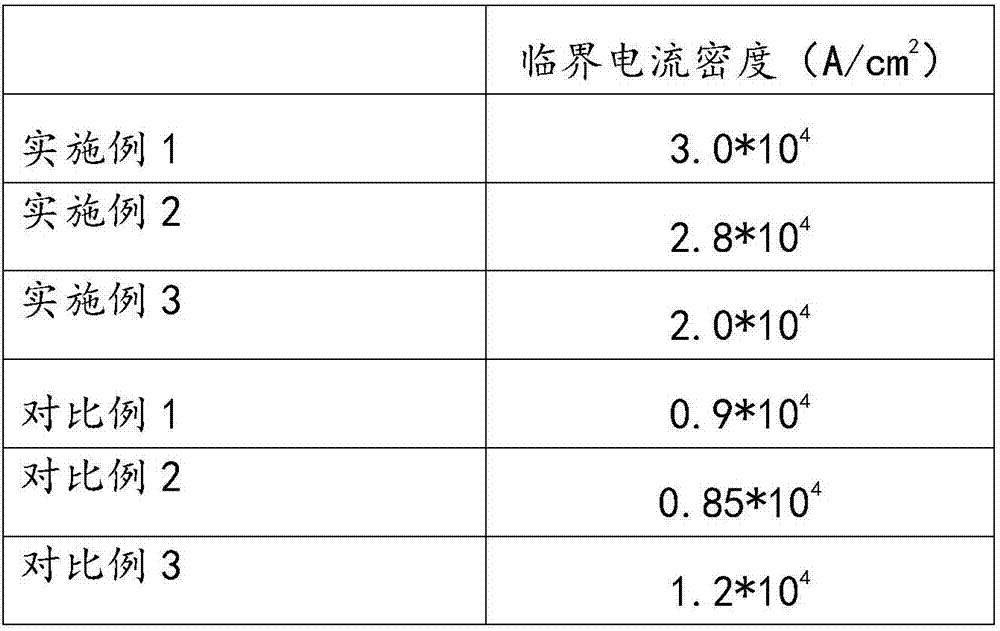

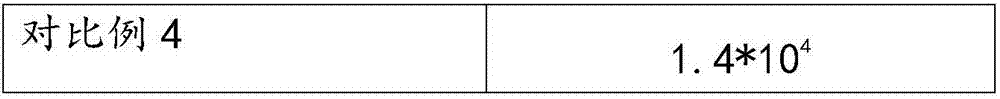

Embodiment 1

[0024] A superconducting thin film material, composed of the following components according to mass percentage: 2.9% yttrium trifluoroacetate, 5.8% barium trifluoroacetate, 2.5% terpineol, 10.5% acetylacetone, 6.5% acetylacetone Zirconium and the balance niobium. During preparation, mix yttrium hydrochloric acid solution, barium hydrochloric acid solution, titanium hydrochloric acid solution, zirconium hydrochloric acid solution and niobium hydrochloric acid solution evenly, the pH value is between 5.0-6.0, remove water to obtain pure gel; add terpineol to prepare The precursor solution is obtained, and coated on the substrate for low-temperature thermal decomposition; after the treated substrate is heat-treated, it is annealed and heat-treated to obtain a superconducting thin film material.

Embodiment 2

[0026] A superconducting thin film material, composed of the following components according to mass percentage: 3.3% yttrium trifluoroacetate, 6.8% barium trifluoroacetate, 2.5% terpineol, 11.5% acetylacetone, 6.5% acetylacetone Zirconium and the balance niobium. During preparation, mix yttrium hydrochloric acid solution, barium hydrochloric acid solution, titanium hydrochloric acid solution, zirconium hydrochloric acid solution and niobium hydrochloric acid solution evenly, the pH value is between 5.0-6.0, remove water to obtain pure gel; add terpineol to prepare The precursor solution is obtained, and coated on the substrate for low-temperature thermal decomposition; after the treated substrate is heat-treated, it is annealed and heat-treated to obtain a superconducting thin film material.

Embodiment 3

[0028] A superconducting thin film material is composed of the following components according to mass percentage: 3.9% yttrium trifluoroacetate, 5.8% barium trifluoroacetate, 2.5% terpineol, 12.5% acetylacetone, 7.5% acetylacetone Zirconium and the balance niobium. During preparation, mix yttrium hydrochloric acid solution, barium hydrochloric acid solution, titanium hydrochloric acid solution, zirconium hydrochloric acid solution and niobium hydrochloric acid solution evenly, the pH value is between 5.0-6.0, remove water to obtain pure gel; add terpineol to prepare The precursor solution is obtained, and coated on the substrate for low-temperature thermal decomposition; after the treated substrate is heat-treated, it is annealed and heat-treated to obtain a superconducting thin film material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com