Preparation method of lightweight porous wheat straw concrete panels

A wheat straw and concrete technology, which is applied in the field of preparation of cement concrete plates, can solve the problems of destroying soil drought resistance and moisturizing ability, existing fire and traffic accidents, environmental pollution, etc., and achieves improvement of self-weight, thermal insulation performance, and good compressive strength. , the effect of good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

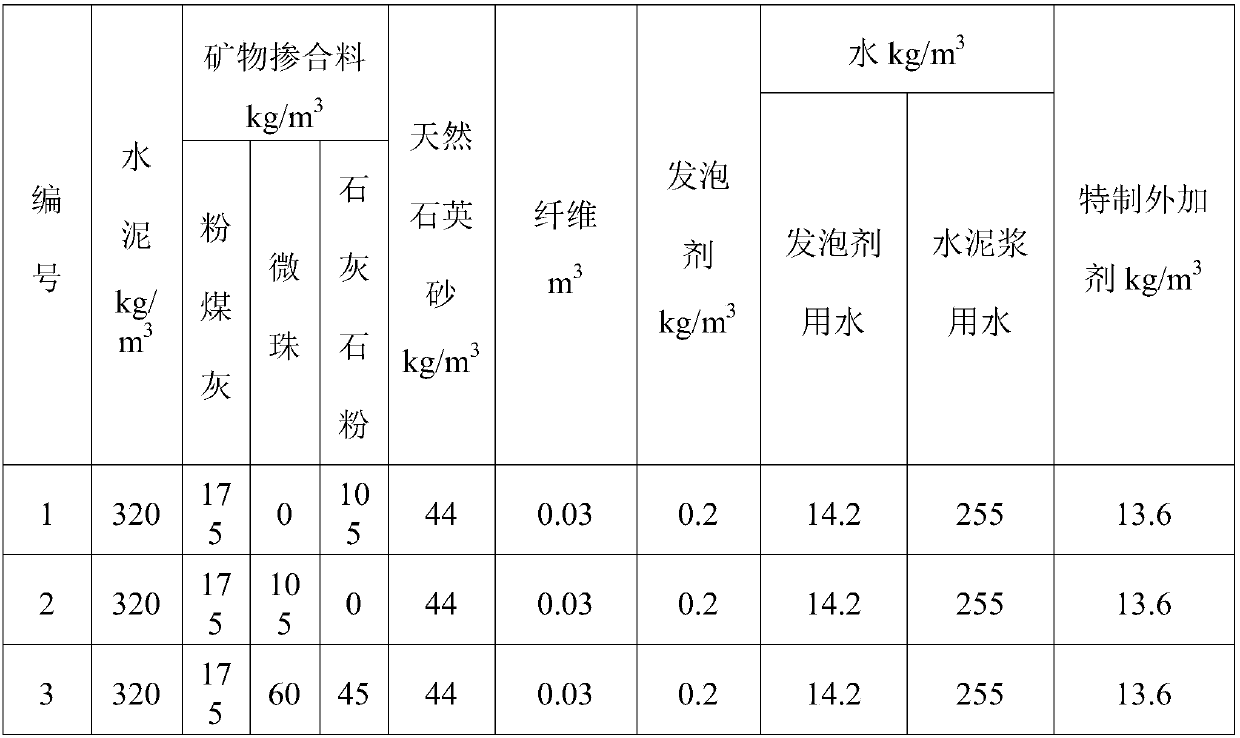

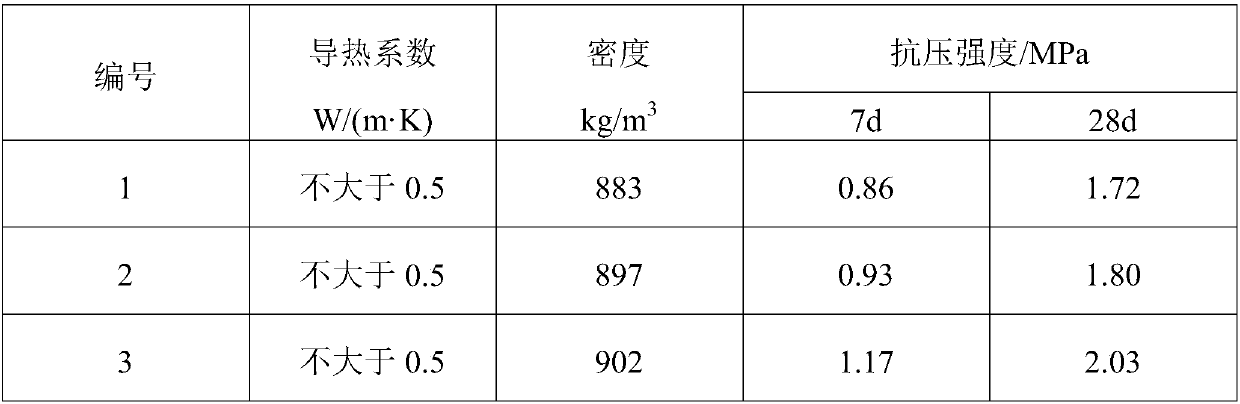

Embodiment 1-3

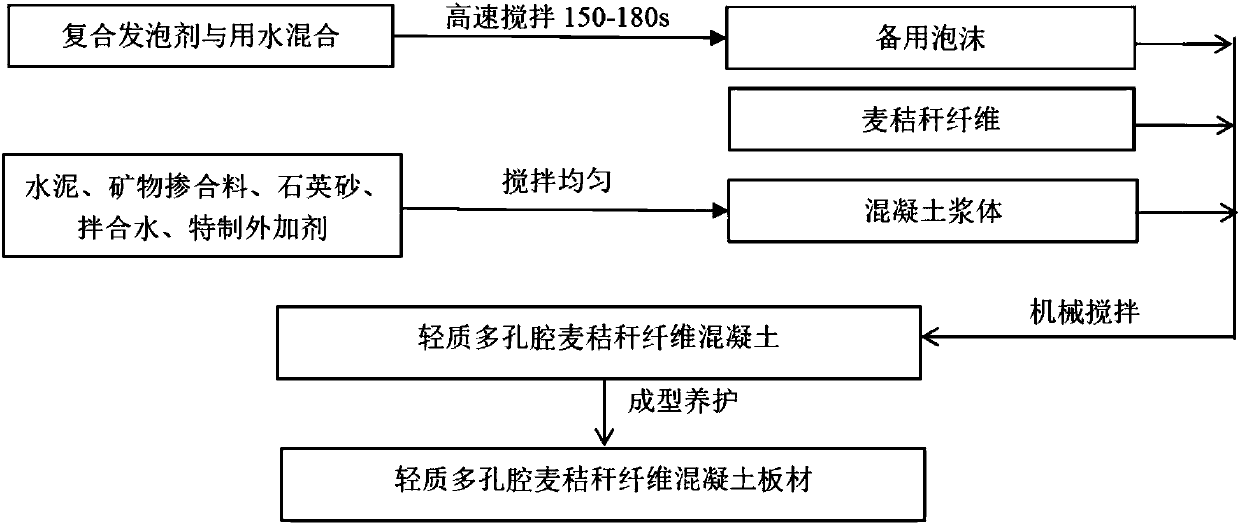

[0024] Step 1: Use a mixer to mechanically stir the composite foaming agent and water to cause foam for later use. The mass ratio of foaming agent to water is 1:(65-75), the high-speed stirring speed is ≥980r / min, and the stirring time is 150-180s;

[0025] Step 2: Mix cement, mineral admixture, quartz sand, mixing water, and special admixture evenly; the mass ratio of cement, mineral admixture, quartz sand, mixing water, and special admixture is 1.10-1.25 :0.80-1.05:0.10-0.15:0.75-0.85:0.03-0.06;

[0026] Step 3: Add the prepared foam and wheat straw fibers into the uniformly mixed cement slurry and mechanically stir; wherein the volumes of the spare foam and wheat straw fibers are respectively 85-125% and 2.25-3.25% of the cement slurry; The length of straw fiber is 0-5mm, and the mechanical stirring speed is ≥320r / min;

[0027] Step 4: After the preparation is completed, pour the concrete into the panel mold and form it with slight vibration. After the panel surface is pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com