Composite material structure based fluid-solid coupling value prediction method

A composite material and fluid-solid coupling technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as insufficient consideration, achieve high-precision numerical prediction, improve reliability, save experimental costs and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

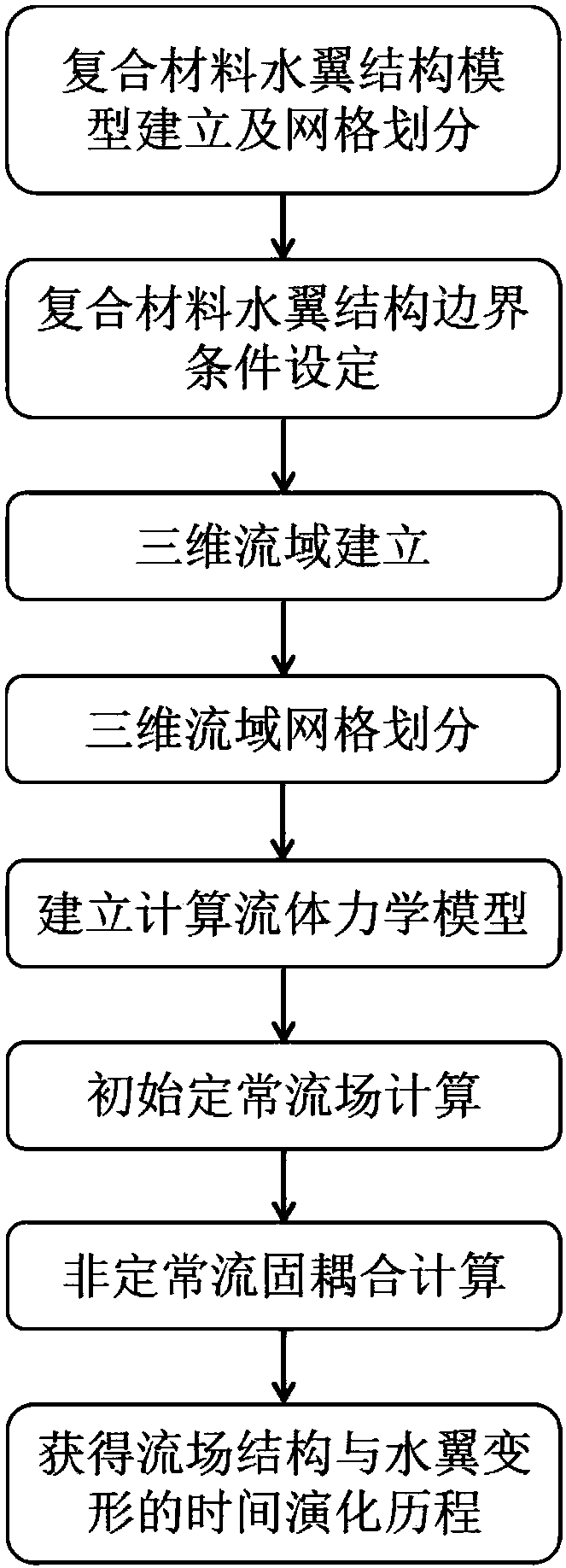

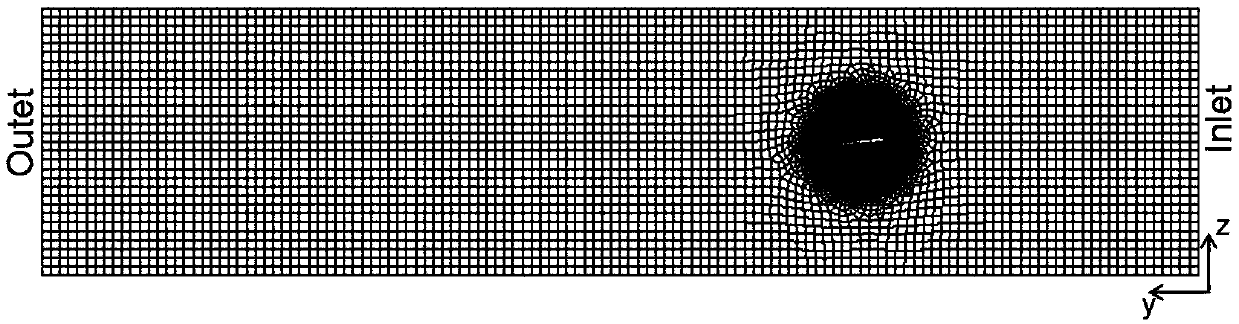

Method used

Image

Examples

Embodiment 1

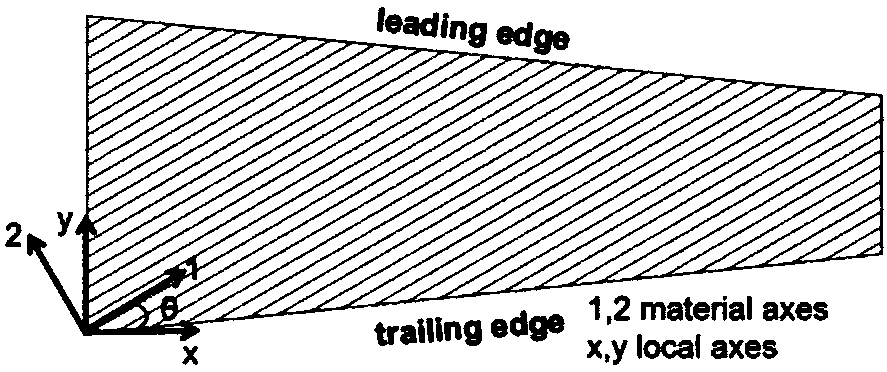

[0045]Under the action of the flow field, the composite material structure will produce large deformation, which will affect the flow field structure and improve the hydraulic performance of the structure. Applied to hydraulic machinery, it can effectively improve the efficiency of hydraulic machinery. In order to obtain a composite material structure that can effectively improve efficiency and guide the actual design and processing, this example adopts a fluid-structure coupling numerical prediction method based on composite material structure, and analyzes the flow of composite hydrofoils under different design parameters. Numerical prediction of solid-coupling characteristics can quickly obtain composite material structures that can effectively improve efficiency. Among them, the design parameter is the ply angle of the partial ply of the composite material. Corresponding to the efficiency of hydraulic machinery, the design goal of composite hydrofoils is the lift-to-drag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com