Aeroengine combustion chamber service life prediction method

An aero-engine and life prediction technology, which is applied in computer-aided design, special data processing applications, instruments, etc., can solve the problems of high experimental cost, inability to accurately reproduce the aero-engine combustion chamber, and inability to reflect the impact of aero-engine combustion chamber life, etc. , to achieve the effect of reducing the number of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

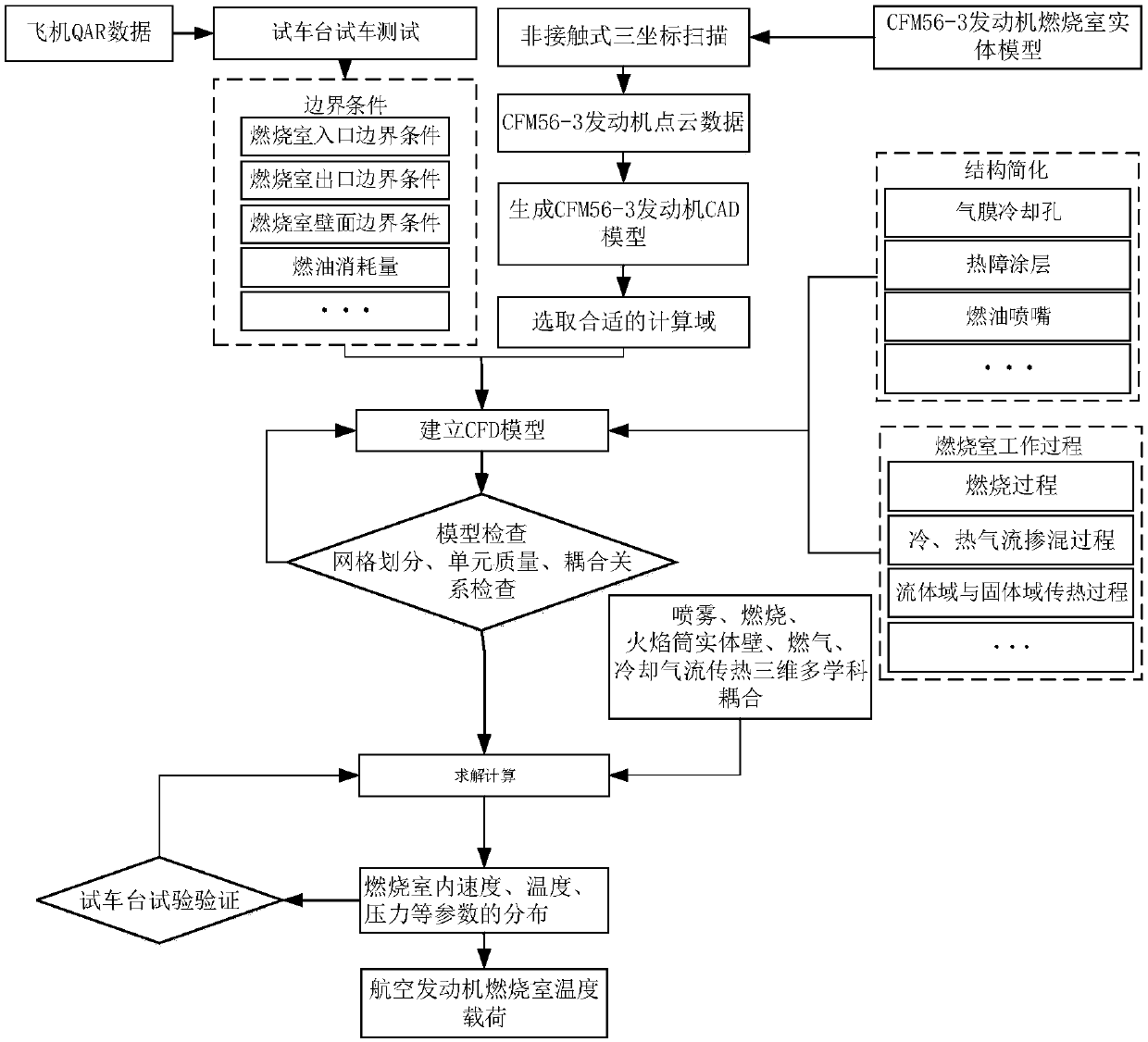

[0026] (1) CFD analysis of the aero-engine combustion chamber: the QAR data of the aircraft can be analyzed to obtain the typical working conditions of the aero-engine, and the engine is tested on the test bench to obtain the aerodynamic parameters of the combustion chamber inlet and outlet during the engine working process and Engine operating state parameters such as fuel consumption; conduct non-contact 3D scanning of the CFM56-3 engine solid model, obtain CFM56-3 engine point cloud data and generate a 3D engine model, and combine the structure of the engine to rationally simplify the 3D model and select the appropriate Computational domain, the grid discretization of the computational domain, considering the combustion process, the mixing process of hot and cold air flow, the heat transfer process between the fluid domain and the solid domain during the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com