Slicing, deep-frying and packing integrated device

A slicing device and slicing technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of needing to transfer bags and high production costs, and achieve the effects of reducing labor intensity, saving production costs, and improving frying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

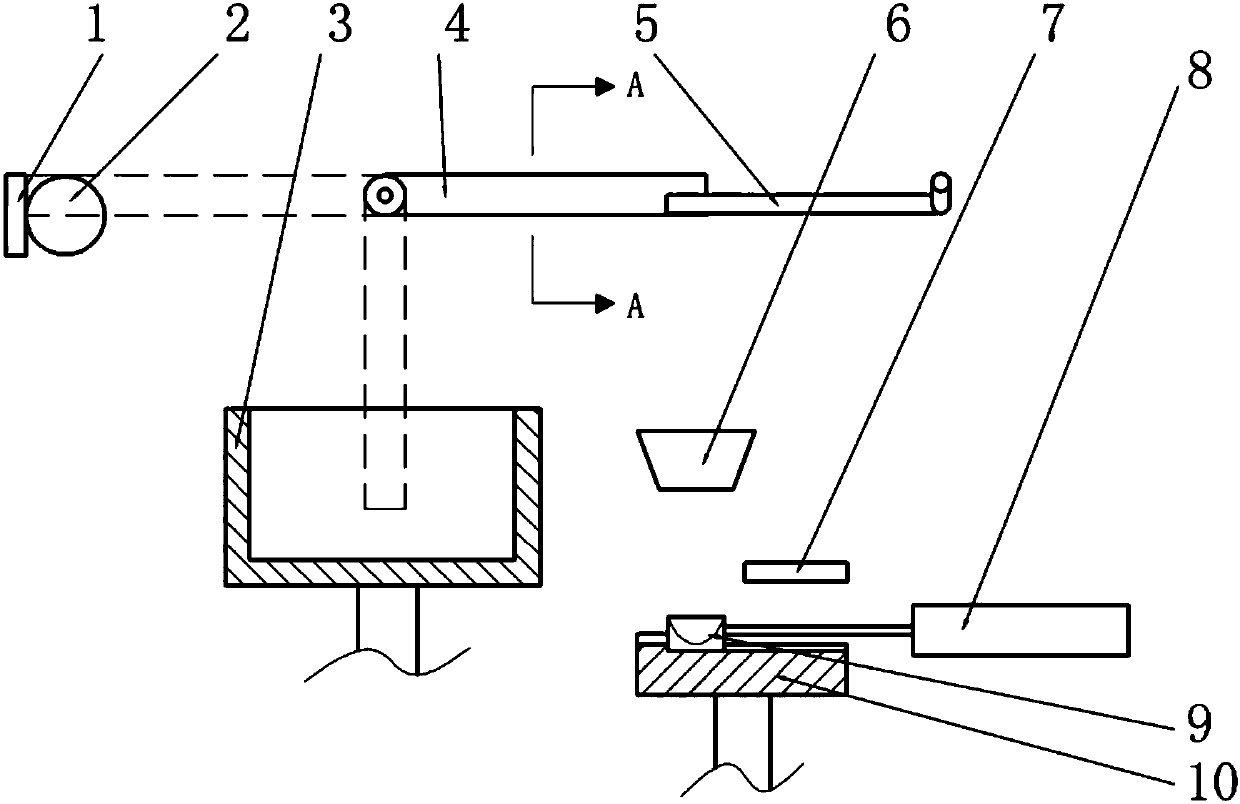

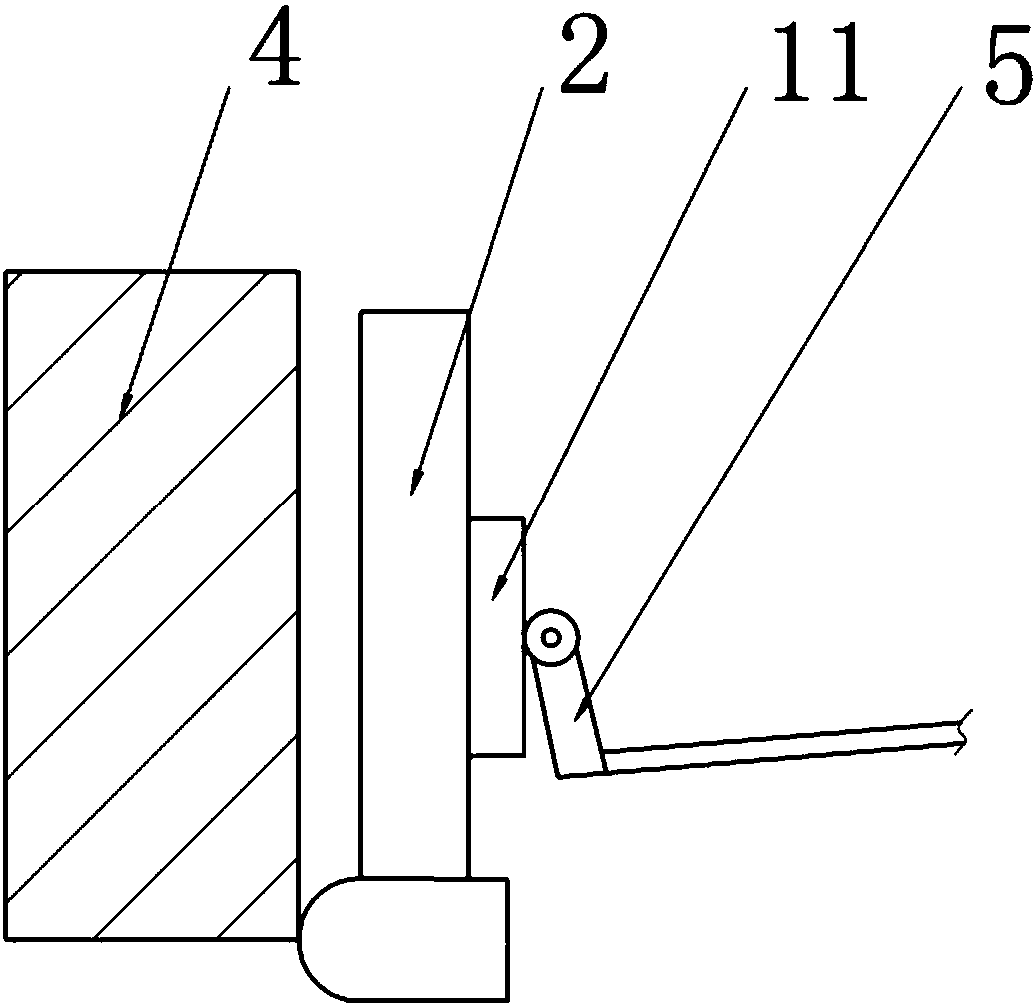

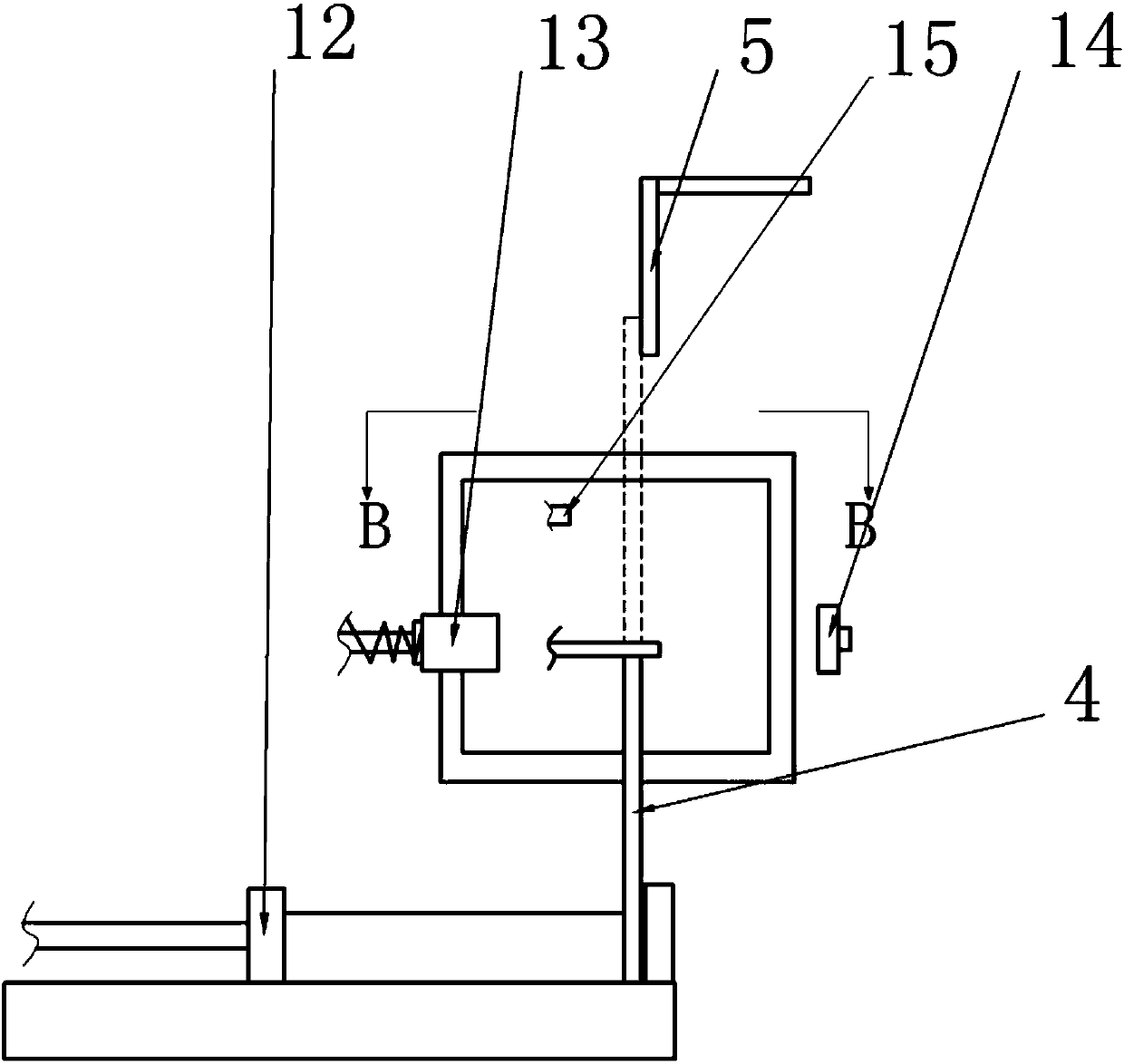

[0028] Embodiment: The integrated device for slicing, frying and packaging in this scheme, such as figure 1 As shown, the output end of the feeding air pump is connected to the inlet end of the feeding cylinder, the feeding cylinder is fixed on the frame 1, a dovetail groove is integrally formed on the feeding plate 12, and a dovetail strip is integrally formed on the frame 1, and the dovetail strip is installed on the In the dovetail groove, the feeding plate 12 is threadedly connected to the output end of the feeding cylinder. The slicing motor is fixedly connected to the frame 1 through anchor bolts. Cutter 4 is plate-shaped, and cutter 4 is made of steel, and cutter 4 keys are connected on the output shaft of slicing motor, and the junction of cutter 4 and slicing motor is positioned at the top of frying tank 3 . Such as Figure 5 As shown, the inserting plate 18 is strip-shaped, and the inserting plate 18 is made of a magnetic conductor. Inserting plate 18 bearing pins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com