Kitchen garbage treatment device

A technology of food waste and treatment device, which is applied in the direction of grease/oily substance/floating matter removal device, transportation and packaging, liquid carbon-containing fuel, etc., which can solve the complex composition of food waste, environmental pollution, and increase of sewage in urban pipe network Dealing with burdens etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

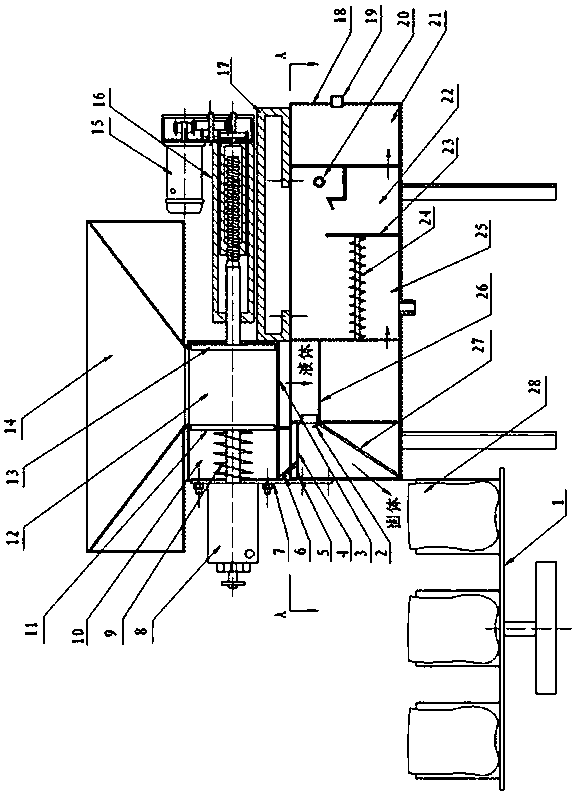

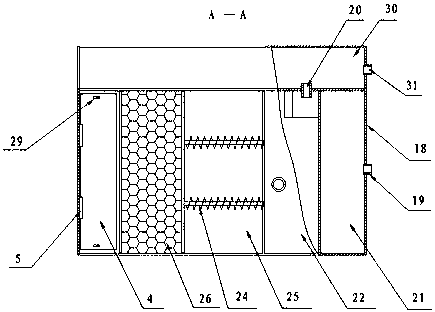

[0022] In order to have a further understanding and understanding of the structural features and the achieved effects of the present invention, a detailed description is provided with preferred embodiments and accompanying drawings: a kitchen waste treatment device, including a rapid extrusion component, an electromagnetic Suction assembly, solid-liquid separation chamber, box 18. The quick extrusion assembly includes a motor 15, an electric telescopic rod 16, and an extrusion plate 13; the electromagnetic attraction assembly includes an electromagnet 8, an electromagnet spring 9, and a solid material pressing plate 11; the solid-liquid separation chamber includes a solid The material chamber part 10 and the solid-liquid separation chamber part 12, the box body 18 includes a space for setting a filter partition 26, a space for setting a movable plate 4 and a slide plate 27, a waste water tank 21, an oil-water separation box 22, a liquid heating box 25, and a waste oil tank 30....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com