Method for preparing dual-shell hollow micro-nano structural TiO2 microspheres by one-step template-hydrothermal process

A micro-nano structure, double-shell technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of high fault tolerance, necessity of complex multi-step synthesis process, cumbersome operation process, etc., to achieve simple operation and save The effect of simple resources and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The following are parts by mass,

[0027] Weigh 15 parts glucose and 1 part (NH 4 ) 2 TiF 6 , dissolved in a certain amount of deionized water, and stirred evenly; the mixture was transferred into a hydrothermal kettle, reacted at 190 °C for 24 hours, and washed several times by centrifugation to obtain black powder; finally, the black powder was treated at high temperature in a muffle furnace, After calcining at 550 °C for 4 h, the white powder was collected, that is, the double-shelled hollow micro-nano-structured TiO 2 Microspheres.

Embodiment 2

[0029] The following are parts by mass,

[0030] Weigh 20 parts of glucose and 2 parts (NH 4 ) 2 TiF 6 , dissolved in a certain amount of deionized water, and stirred evenly; the mixture was transferred into a hydrothermal kettle, reacted at 190 °C for 20 hours, and washed several times with centrifugal water to obtain black powder; finally, the black powder was treated at high temperature in a muffle furnace, After calcining at 550 °C for 4 h, the white powder was collected, that is, the double-shelled hollow micro-nano-structured TiO 2 Microspheres.

Embodiment 3

[0032] The following are parts by mass,

[0033] Weigh 30 parts of glucose and 1 part (NH 4 ) 2 TiF 6 , dissolved in a certain amount of deionized water, and stirred evenly; the mixture was transferred into a hydrothermal kettle, reacted at 190 ° C for 18 hours, and washed several times by centrifugation to obtain black powder; finally, the black powder was processed in a muffle furnace at high temperature, After calcining at 550 °C for 4 h, the white powder was collected, that is, the double-shelled hollow micro-nano-structured TiO 2 Microspheres.

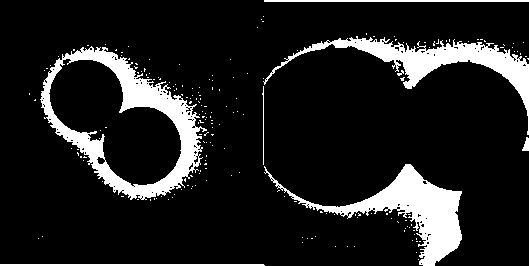

[0034] see figure 1 ,from figure 1 It can be seen from the left and right of the double-shelled hollow micro-nano-structured TiO that can be successfully prepared by a one-step template-hydrothermal method. 2 The particle size of the inner shell is about 400nm, and the particle size of the outer shell is about 1-1.5μm. The hollow structure is obvious, and each sphere is in a monodispersed state with regular morphology.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com