Low-emission and low-smell filling functional master batch and preparation method thereof

A functional masterbatch and low-odor technology, applied in the field of composite materials, can solve problems such as impact performance is greatly affected, and achieve excellent dispersion, broad market prospects, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~2

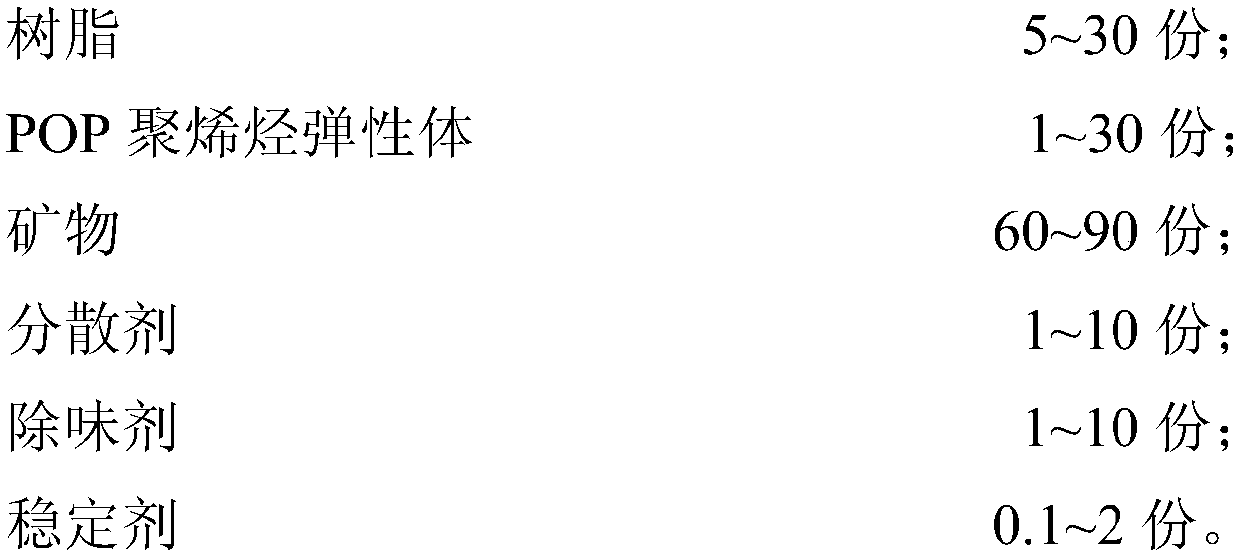

[0036] The present invention prepares low-emission and low-odor filling functional masterbatches. The raw material ratios of Examples 1-6 and Comparative Examples 1-2 are listed in the following Tables 1 and 2 respectively. Unless otherwise specified, the percentages refer to weight percentages.

[0037] The preparation method of filling functional masterbatch with low emission and low odor comprises the following steps:

[0038] Add minerals to the mixer, heat to 60 degrees Celsius, then add POP elastomer and dispersant, mix well and then add resin, add deodorant during stirring, and finally add stabilizer, mix well and send into Extrusion and granulation in the two-stage screw granulation unit, the speed of the single-screw extruder is 100 rpm, the speed of the twin-screw host is 600 rpm, and the temperature of each section of the screw is 160 ° C ~ 200 ° C; during the granulation process Using multi-stage vacuum suction, the vacuum pressure is kept at 0.08MPA, and the granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com