Flame-retardant board for space leasing and preparation method thereof

A space and plate technology, applied in the field of flame retardant plates for space leasing and its preparation, can solve the problems of high application cost of flame retardant and smoke suppressant, difficulty in synthesis, etc., achieve high promotion and application value, reduce production cost, and improve mechanical properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of flame-retardant panels for space leasing:

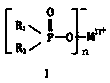

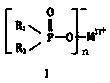

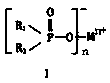

[0049] (1) Preparation of flame retardant and smoke suppressant: In parts by weight, 10 parts of phosphinate with R1 and R2 substituents as shown in formula (I), 1 part of tributyltin and 6 parts of tri-n-octyl oxide Phosphine was mixed at 240°C for 20min, and then kept at 260°C for 1.5h, wherein, R 1 is methyl; R 2 Be phenyl, M is Al, n is 3, obtains flame retardant and smoke suppressant A1;

[0050] (2) In parts by weight, 75 parts of PVC-SG5 polyvinyl chloride, 100 parts of nano-scale calcium carbonate, 2 parts of dimethyl tin oxide PVC stabilizer, 0.5 parts of stearic acid, ACR K-123 modifier 2 parts and 15 parts of flame retardant and smoke suppressant A1, hot mixed at 120°C for 1.5h, then cold mixed at 60°C for 20min, and then extruded at 160°C.

[0051]

Embodiment 2

[0053] Preparation of flame-retardant panels for space leasing:

[0054] (1) Preparation of flame retardant and smoke suppressant: In parts by weight, 10 parts of phosphinate with R1 and R2 substituents as shown in formula (I), 2 parts of tributyltin and 8 parts of tri-n-octyl oxide Phosphine was mixed at 245°C for 25min, and then kept at 270°C for 2h, wherein, R 1 is n-propyl; R 2 It is an isopropyl group substituted by a hydroxyl group at the 1 position, M is Al, and n is 3 to obtain the flame retardant and smoke suppressant A2;

[0055] (2) In parts by weight, 100 parts of PVC-SG5 polyvinyl chloride, 125 parts of nano-scale calcium carbonate, 4.5 parts of dimethyl tin oxide PVC stabilizer, 0.8 parts of stearic acid, ACR K-123 modifier 2.8 parts and 20 parts of flame retardant and smoke suppressant A2, hot mixed at 130°C for 1.2h, then cold mixed at 70°C for 30min, and then extruded at 180°C.

Embodiment 3

[0057] Preparation of flame-retardant panels for space leasing:

[0058] (1) Preparation of flame retardant and smoke suppressant: In parts by weight, 10 parts of phosphinate with R1 and R2 substituents as shown in formula (I), 3 parts of tributyltin and 10 parts of tri-n-octyl oxide Phosphine was mixed at 250°C for 30min, and then kept at 280°C for 2.5h, wherein, R 1 For the n-hexyl substituted by chlorine at the 6-position; R 2 It is a methyl group substituted by an amino group, M is Al, and n is 3, and the flame retardant and smoke suppressant A3 is obtained.

[0059] (2) In parts by weight, 120 parts of PVC-SG5 polyvinyl chloride, 150 parts of nano-scale calcium carbonate, 7 parts of dimethyl tin oxide PVC stabilizer, 1.2 parts of stearic acid, ACR K-123 modifier 3.5 parts and 25 parts of flame retardant and smoke suppressant A3, hot mixed at 140°C for 2 hours, then cold mixed at 80°C for 40 minutes, and then extruded at 210°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com