Synthetic method for ytterbium-and-erbium-codoped KGdF<4> nanoparticle and nanoribbon

A nanoparticle and synthesis method technology, applied in nanotechnology, nanooptics, nanotechnology and other directions, can solve the problems of large product size, high temperature, large synthesis size, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

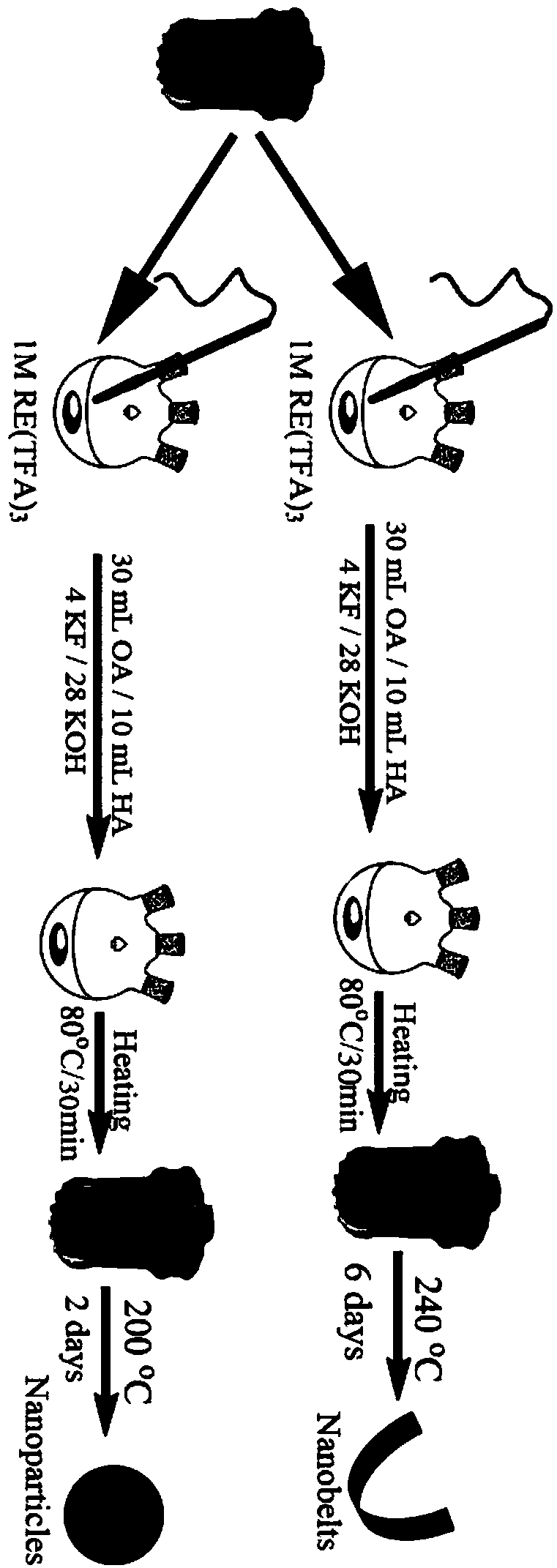

[0034] (1) Preparation of the precursor: the rare earth oxide 78% Gd with a total molar mass of 2 mmoles 2 o 3 and other doped rare earth oxides Ln 2 o 3 (Ln=20%Yb, 2%Er) was added into a 50mL high-temperature reactor, and then a mixed solution of trifluoroacetic acid and water (the volume ratio of trifluoroacetic acid and water was 2:9) was added with a volume of 22mL, and then React for 12-24h in an electric heating constant temperature blast drying oven at 80-140°C. After the reactor was cooled for 12 hours, two parts were equally divided and transferred to three-necked round-bottomed flasks, and then stirred and dried at 60°C for 8 hours to obtain two parts of trifluoroacetate precursor of white solid powder.

[0035] (2) Ytterbium Erbium Co-doped KGdF 4 Preparation of nanoparticles and tapes: Add 30mL oleic acid and 10mL n-hexanol into the three-necked round-bottomed flask containing the above-mentioned white solid trifluoroacetate precursor, mix them evenly under vig...

example 1

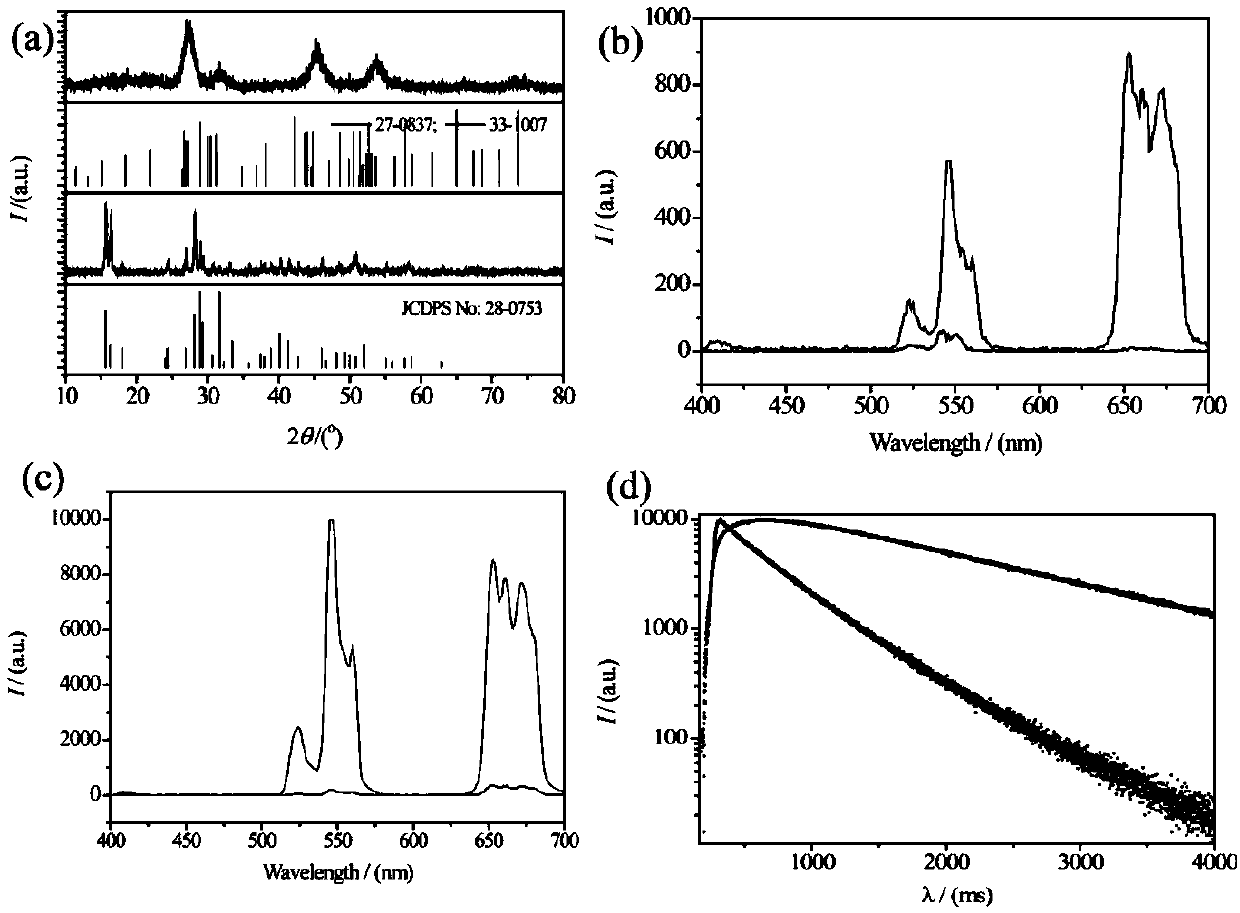

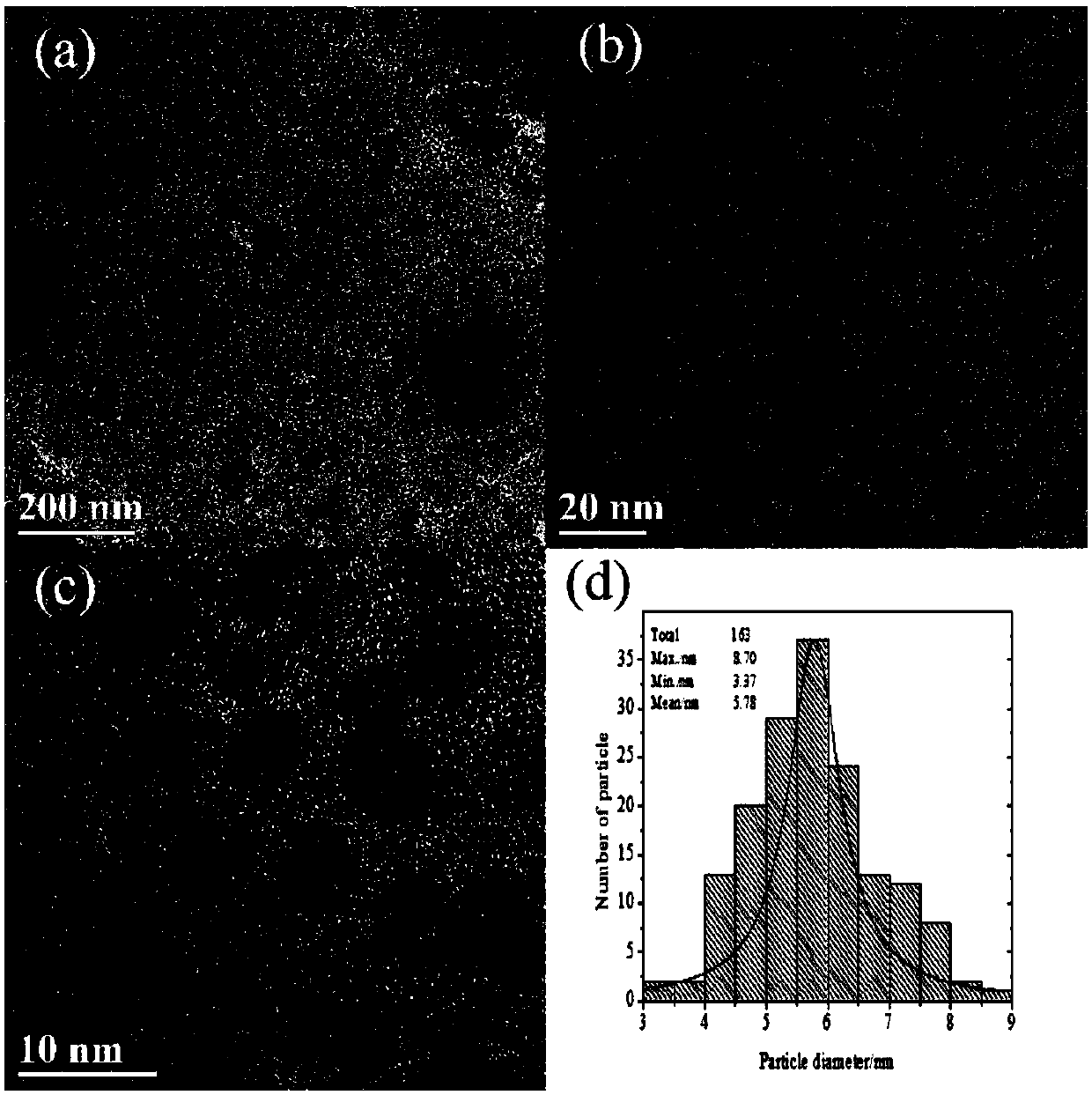

[0036] Example 1: KGdF 4 : Preparation of 20%Yb, 2%Er nanoparticles

[0037] Weigh 0.0038g erbium oxide (Er 2 o 3 ), 0.0394g ytterbium oxide (Yb 2 o 3 ) and 0.1414 g gadolinium oxide (Gd 2 o 3 ) was added to a 100mL high-temperature reactor, and then a mixed solution of trifluoroacetic acid and water (volume ratio=2:9) with a total volume of 11mL was added, and the reaction was carried out in an electric thermostat blast drying oven at 80°C for 24h. After the reactor was cooled for 12 hours, it was transferred to four 100 mL three-neck round bottom flasks, and then stirred and dried at 60° C. for 8 hours to obtain a white solid powder trifluoroacetate precursor. A total volume of 30mL of oleic acid (OA) and 10mL of n-hexanol mixed solution was added to the above-mentioned three-necked flask containing the white solid trifluoroacetate precursor, and it was mixed evenly under vigorous stirring to obtain a light yellow transparent clear solution, weighing Add 4 mmol KF and 2...

example 2

[0040] Example 2: KGdF 4 : Preparation of 20%Yb, 2%Er nanoparticles

[0041] Weigh 0.0038g erbium oxide (Er 2 o 3 ), 0.0394g ytterbium oxide (Yb 2 o 3 ) and 0.1414 g gadolinium oxide (Gd 2 o 3 ) was added to a 100mL high-temperature reactor, and then a mixed solution of trifluoroacetic acid and water (volume ratio=2:9) with a total volume of 11mL was added, and the reaction was carried out in an electric thermostat blast drying oven at 80°C for 24h. After the reactor was cooled for 12 hours, it was transferred to four 100 mL three-neck round bottom flasks, and then stirred and dried at 60° C. for 8 hours to obtain a white solid powder trifluoroacetate precursor. A total volume of 30mL of oleic acid (OA) and 30mL of n-hexanol mixed solution was added to the above-mentioned three-necked flask containing the white solid trifluoroacetate precursor, and it was mixed evenly under vigorous stirring to obtain a light yellow transparent clear solution, which was weighed as Add 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com